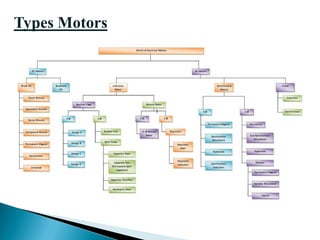

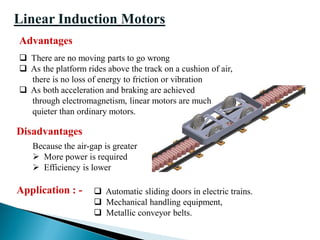

DC motors have advantages like easy speed control but disadvantages like sparks and noise. There are several types of DC motors including shunt wound, series wound, compound wound, and permanent magnet. AC motors are more common and include induction motors, which are the most widely used. Induction motors have constant speed and are robust but lack speed control. Other AC motor types include synchronous, repulsion, hysteresis, and linear induction motors. Stepper motors are useful for precise positioning.