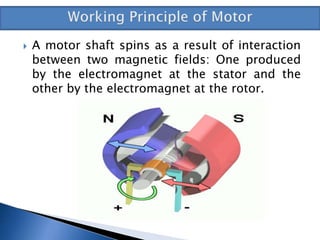

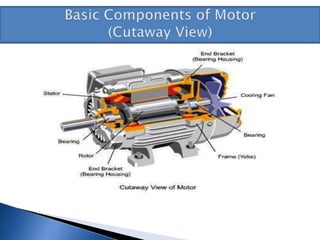

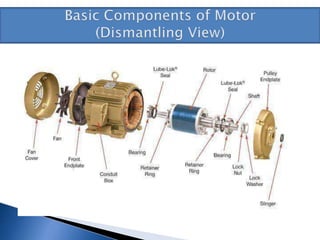

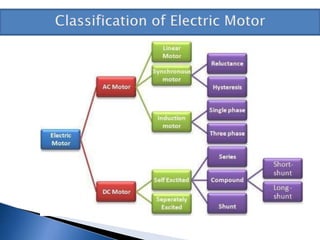

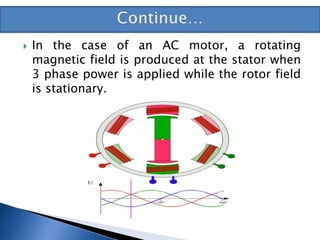

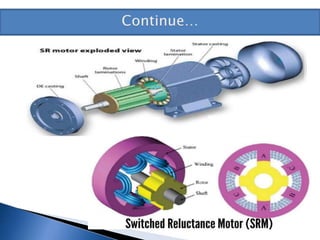

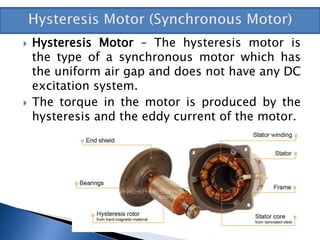

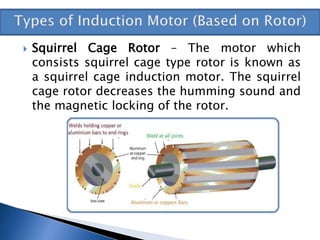

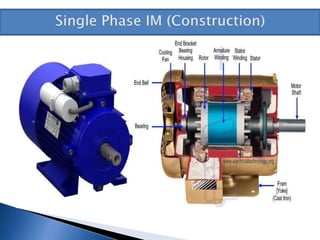

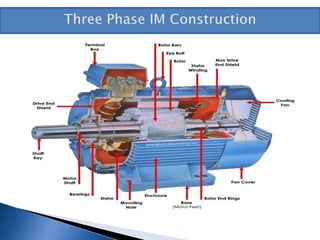

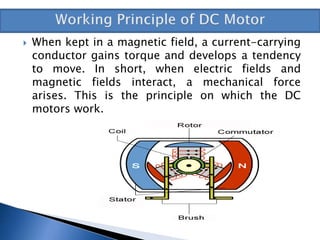

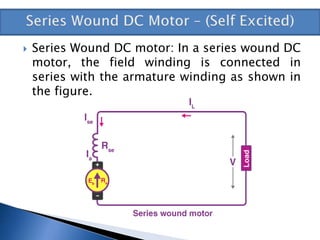

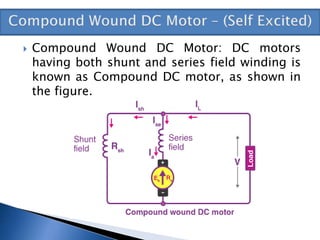

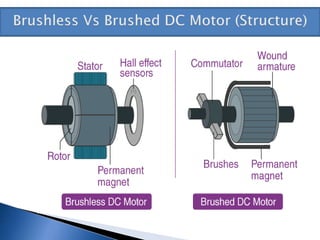

The document is a comprehensive presentation on electric motors, covering their definitions, principles, types (AC and DC), components, and applications. It details the workings of different motor types including synchronous, induction, and brushless motors while highlighting their construction and operational mechanisms. The history of electric motors and notable inventors such as Thomas Davenport and their contributions to the field is also discussed.