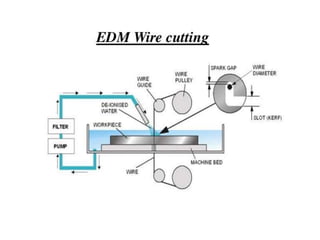

Wire cut EDM uses a thin wire as the electrode to cut complex shapes into difficult-to-machine materials like tungsten carbide. The process involves using a CNC machine to move the workpiece near the vertically moving wire while a dielectric fluid flows between them. Electrical sparks erode small amounts of material from both the wire and workpiece, with the fluid flushing away debris. Key aspects that enable the precision process include a servo system to maintain a small gap, water-based dielectric fluid for initiating sparks and cooling, and characteristics of the consumable wire electrode.