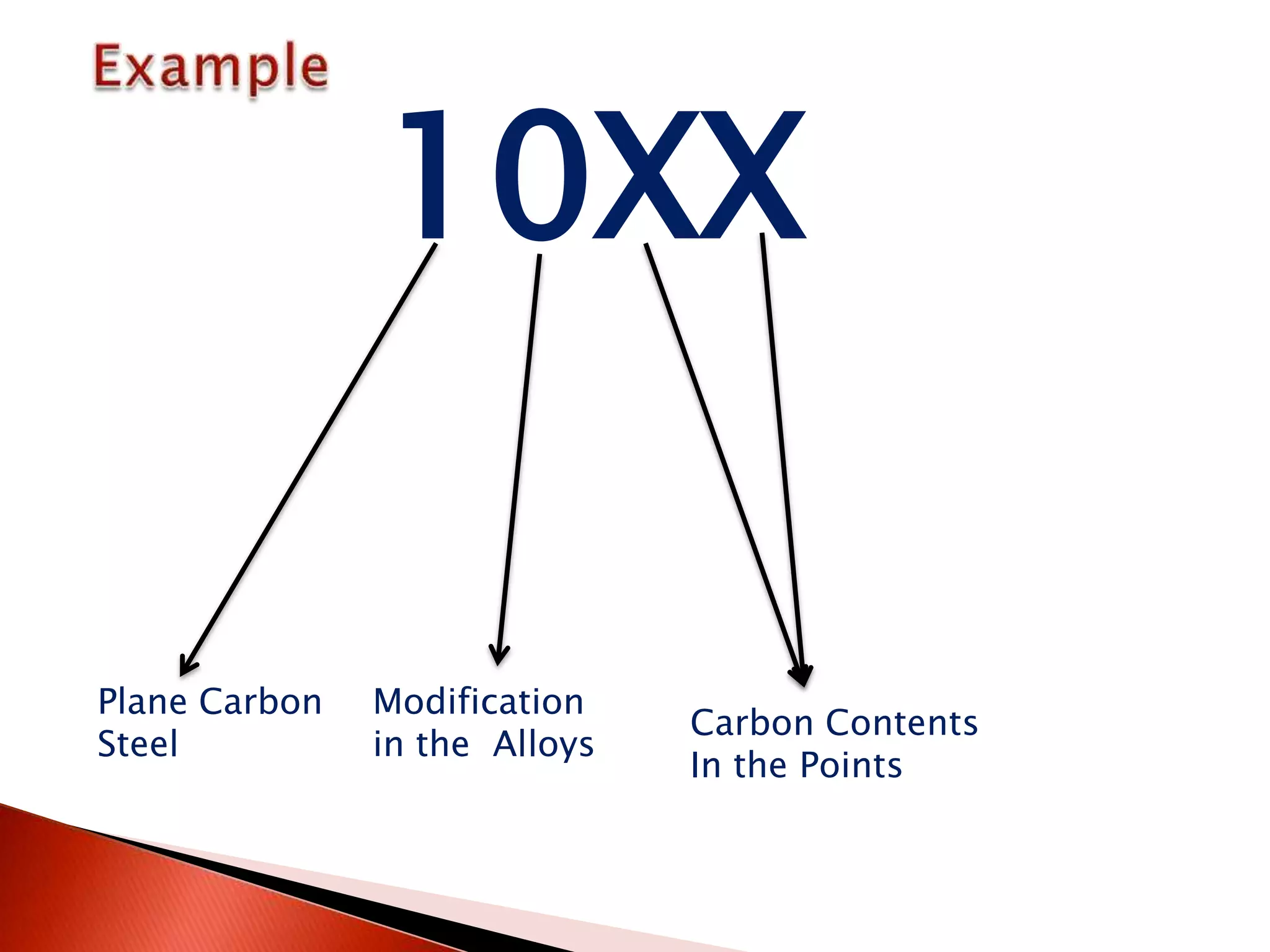

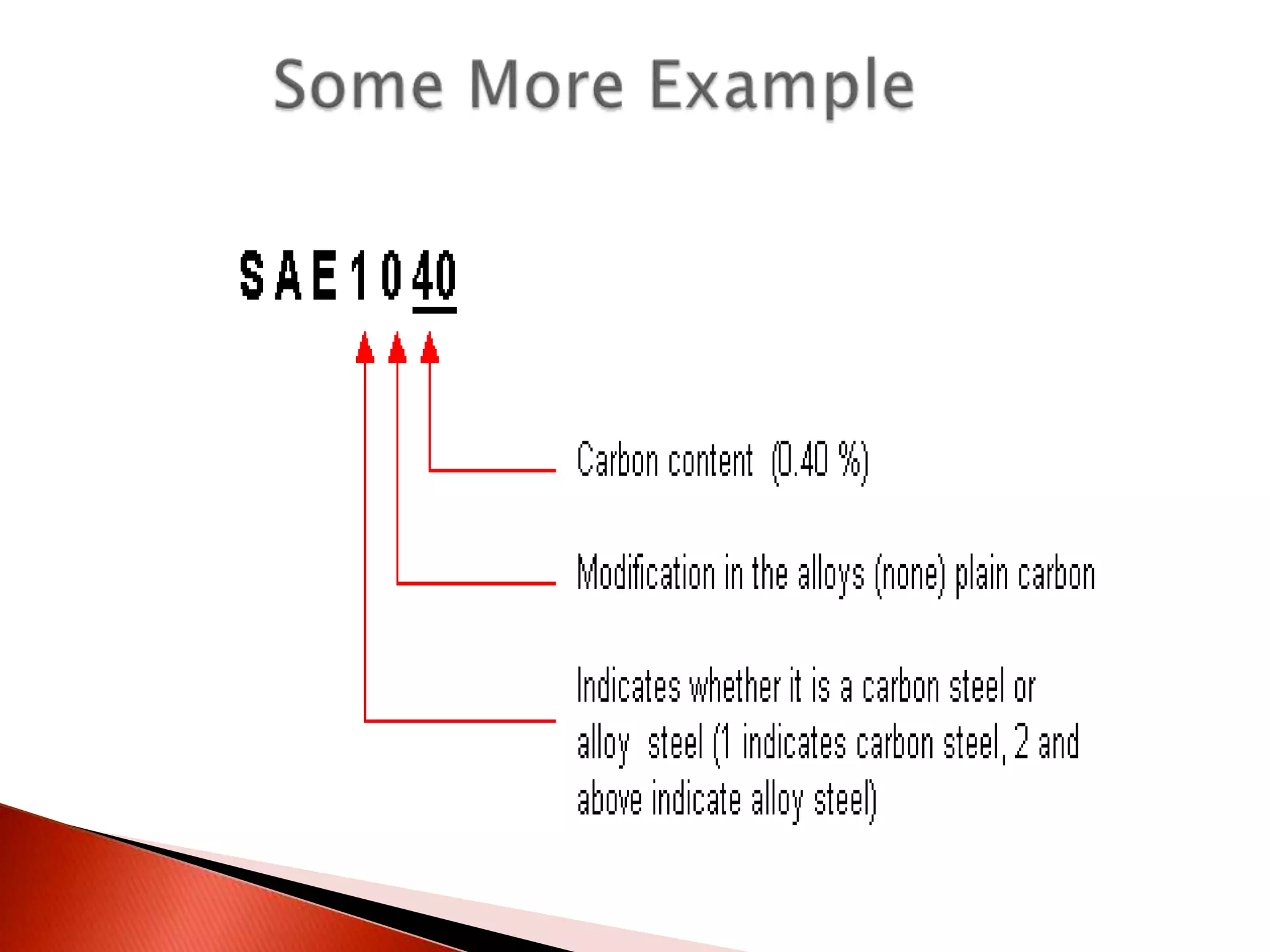

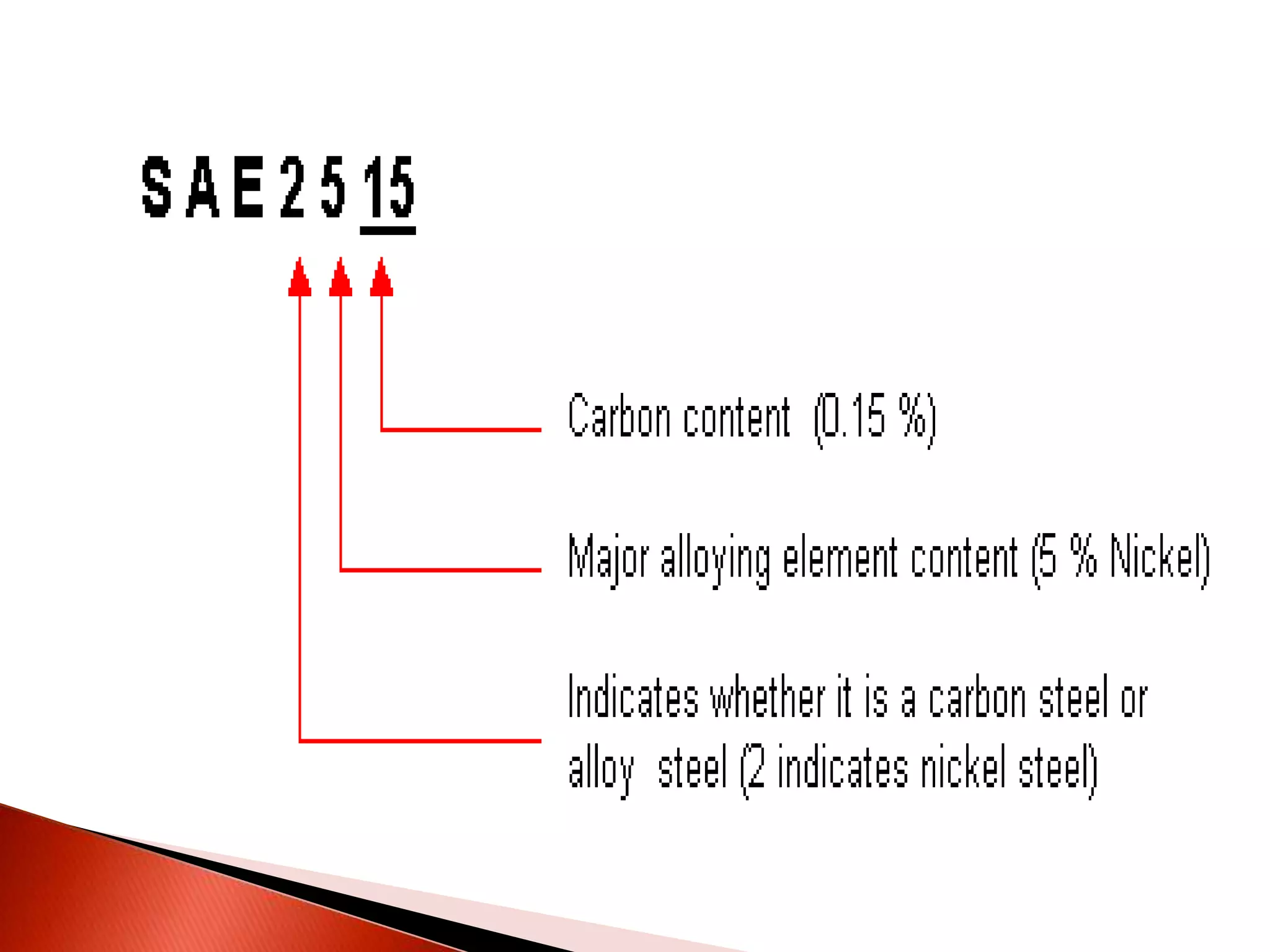

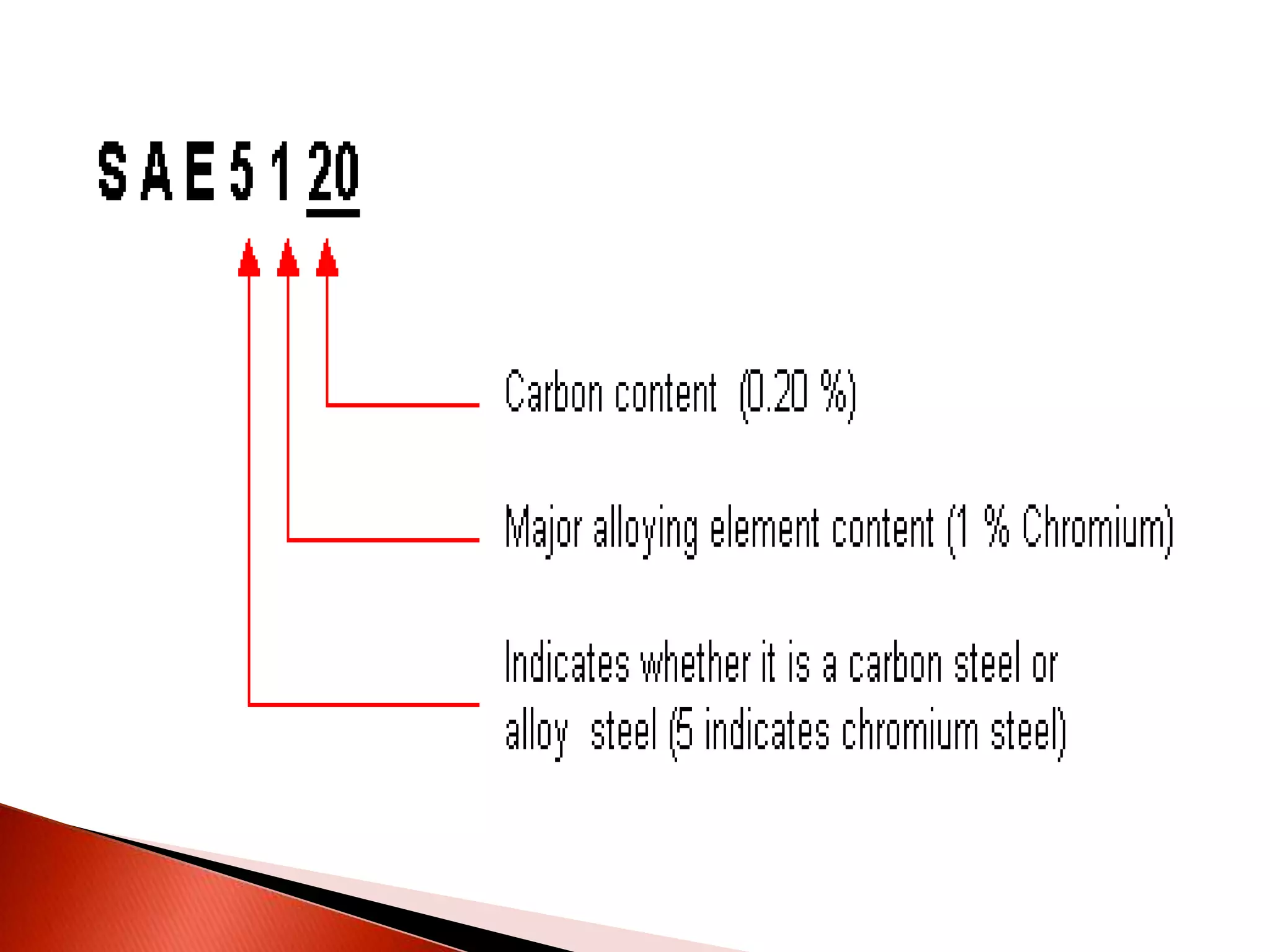

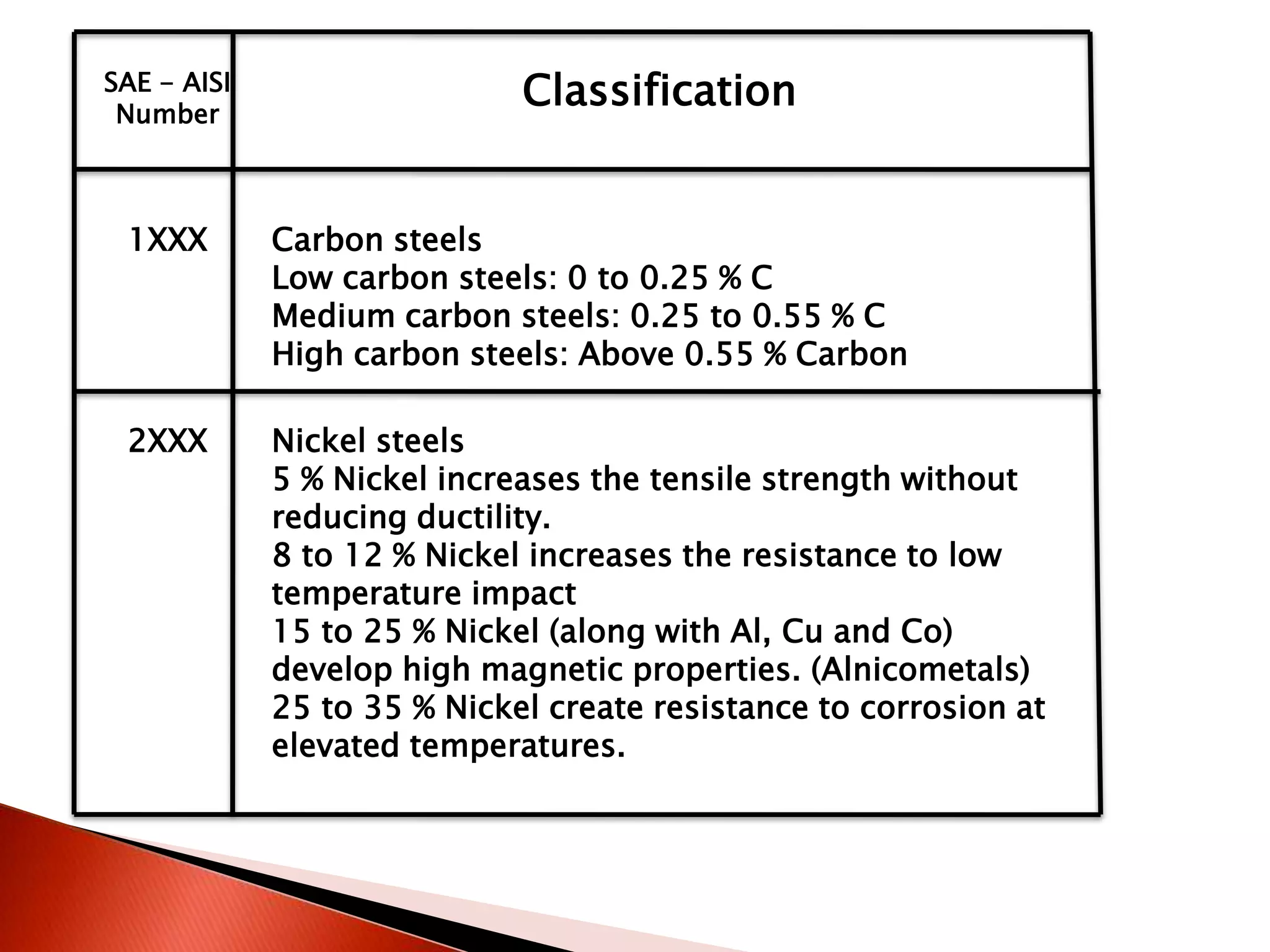

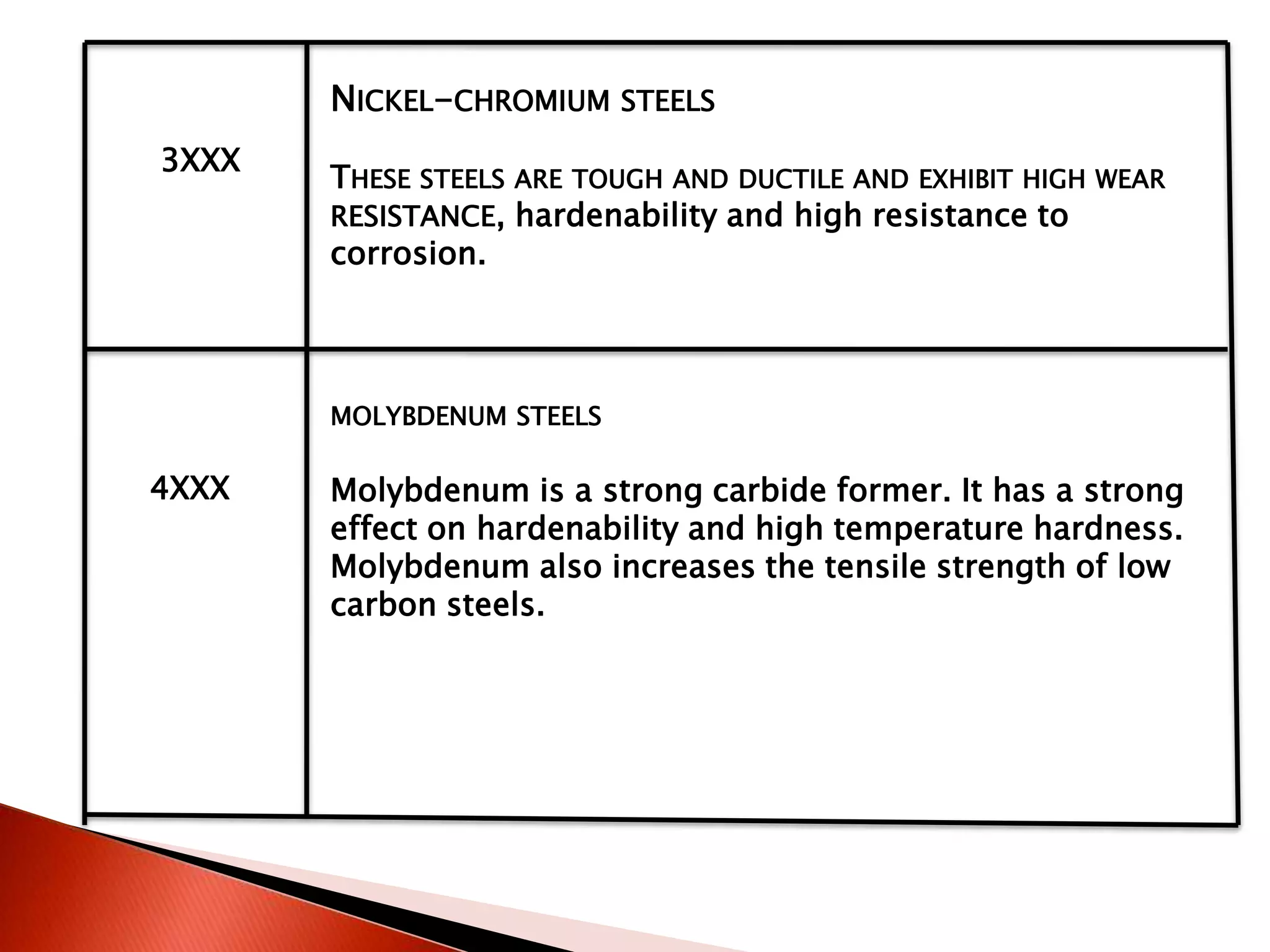

The document discusses different classifications of steel based on carbon content and other alloying elements. It describes plain carbon steels, low alloy steels, and high alloy steels. Within these classifications it discusses ranges of carbon content and how that affects properties like hardness, strength and weldability. It also describes different types of stainless steel (austenitic, ferritic, martensitic) and how alloying elements like chromium and nickel are used to achieve desired properties in stainless steels.