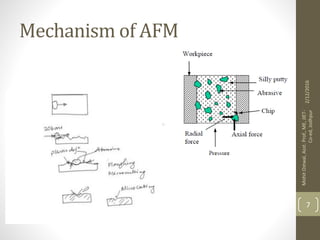

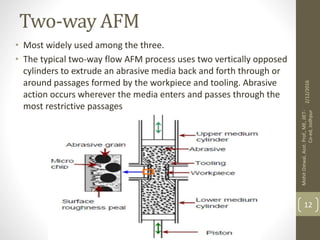

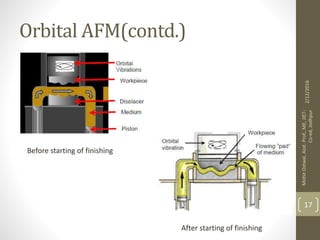

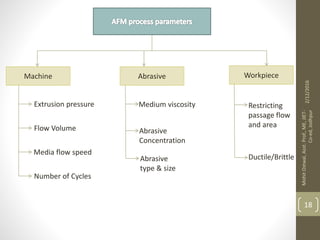

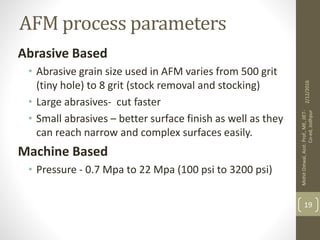

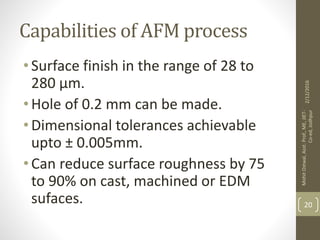

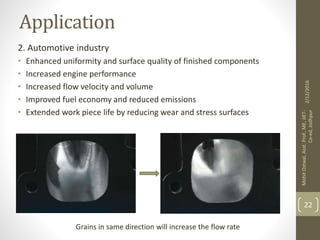

Abrasive flow machining is a deburring and surface finishing process that uses abrasive particles mixed in a viscoelastic medium. It can polish internal surfaces, holes, and intersecting holes. The document discusses the need for AFM, abrasive materials used, the one-way, two-way, and orbital classification methods, process parameters like pressure and abrasive size, capabilities like surface finish ranges and tolerances, and applications in aerospace, automotive, die and mold making, and medical industries to improve surfaces, reduce wear, increase performance, and extend component life.