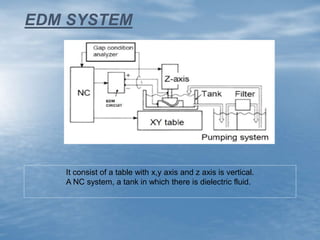

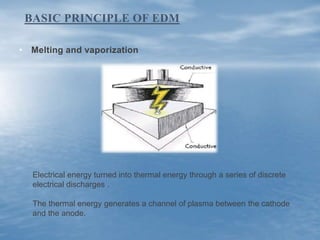

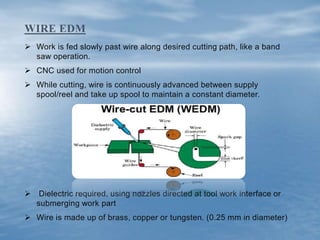

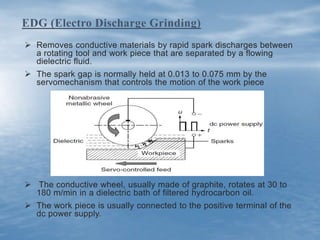

Electrical discharge machining (EDM) is a non-traditional machining process that uses electrical sparks to remove metal. The document discusses the history and development of EDM, including key components like the electrode, workpiece, dielectric fluid, and power supply. It describes the basic EDM process and different EDM methods like conventional EDM, wire EDM, and hole drilling EDM. The document also covers EDM applications, innovations like dry EDM and powder-mixed EDM, and concludes with a list of references.