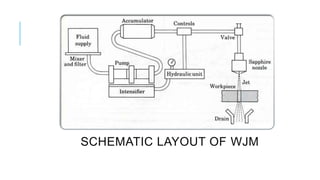

Water jet machining uses a high-pressure stream of water to cut materials. It is a cold cutting process that produces no heat-affected zones. The water jet travels at supersonic speeds and erodes material when the local pressure exceeds the material's strength. Key components include a hydraulic pump to pressurize water, an intensifier to further pressurize it, and a nozzle to direct the jet. It can cut a variety of materials and offers advantages over other cutting methods like reduced burrs, flexibility of cutting complex shapes, and not producing heat or fumes. However, it is not suitable for high-volume production.

![CATCHER

Acts as a reservoir for collecting the machining debris entrained in the water

jet.

Moreover, it reduces the noise levels [105 decibels (dB)] associated with the

reduction in the velocity of the water jet from Mach 3 to subsonic levels.](https://image.slidesharecdn.com/2tehepznsvk6ucmryas5-signature-c256ef937ea36a64c3a7bc4b5e1a8df119999a179ea10a1db46f957c22371c80-poli-140714141436-phpapp02/85/Water-jet-machining-13-320.jpg)