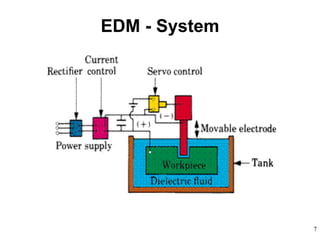

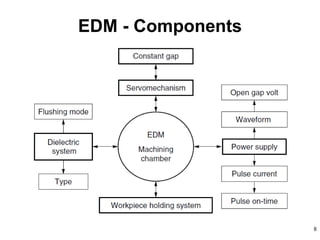

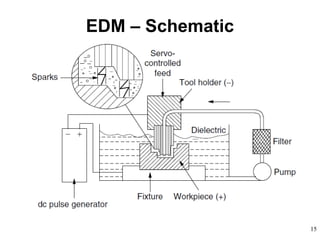

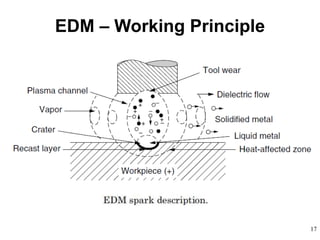

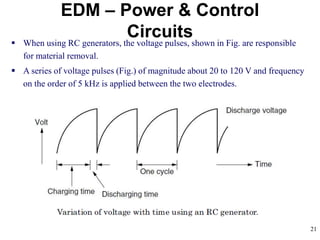

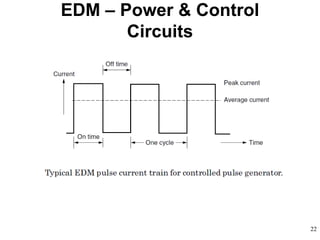

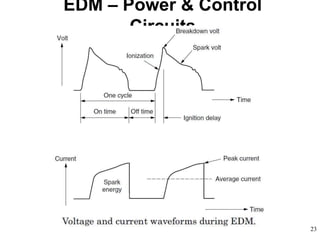

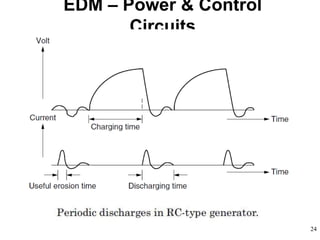

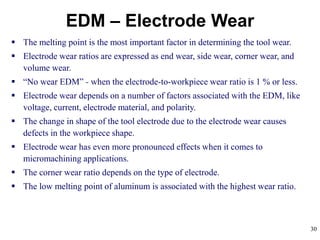

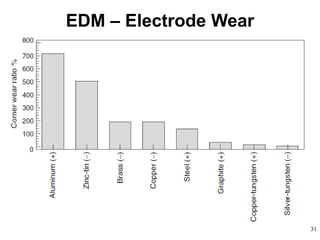

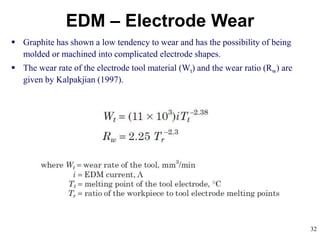

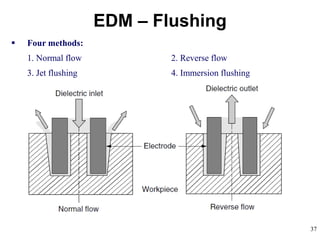

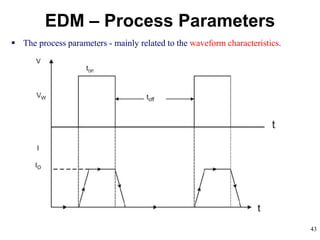

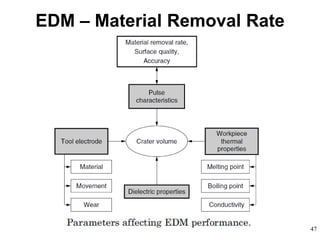

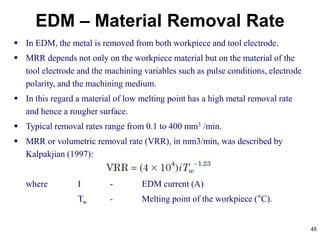

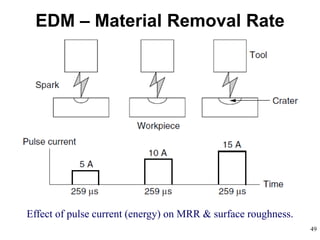

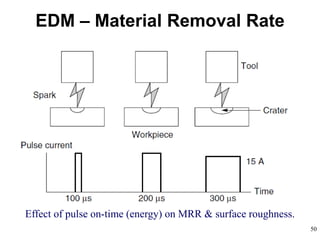

The document discusses Electrical Discharge Machining (EDM). EDM is a manufacturing process where a desired shape is obtained by removing material from a workpiece using electrical discharges between two electrodes separated by a dielectric liquid. As the distance between the electrodes is reduced, current flows due to dielectric breakdown causing material removal from both electrodes. EDM was invented in the 1940s and has since improved, increasing machining speeds and reducing costs. EDM can machine hard metals and intricate shapes without needing to soften the material. The main components of an EDM system are the power supply, dielectric medium, workpiece and tool electrodes, and servo control unit. Material is removed through the formation and collapse of plasma channels between the electrodes during