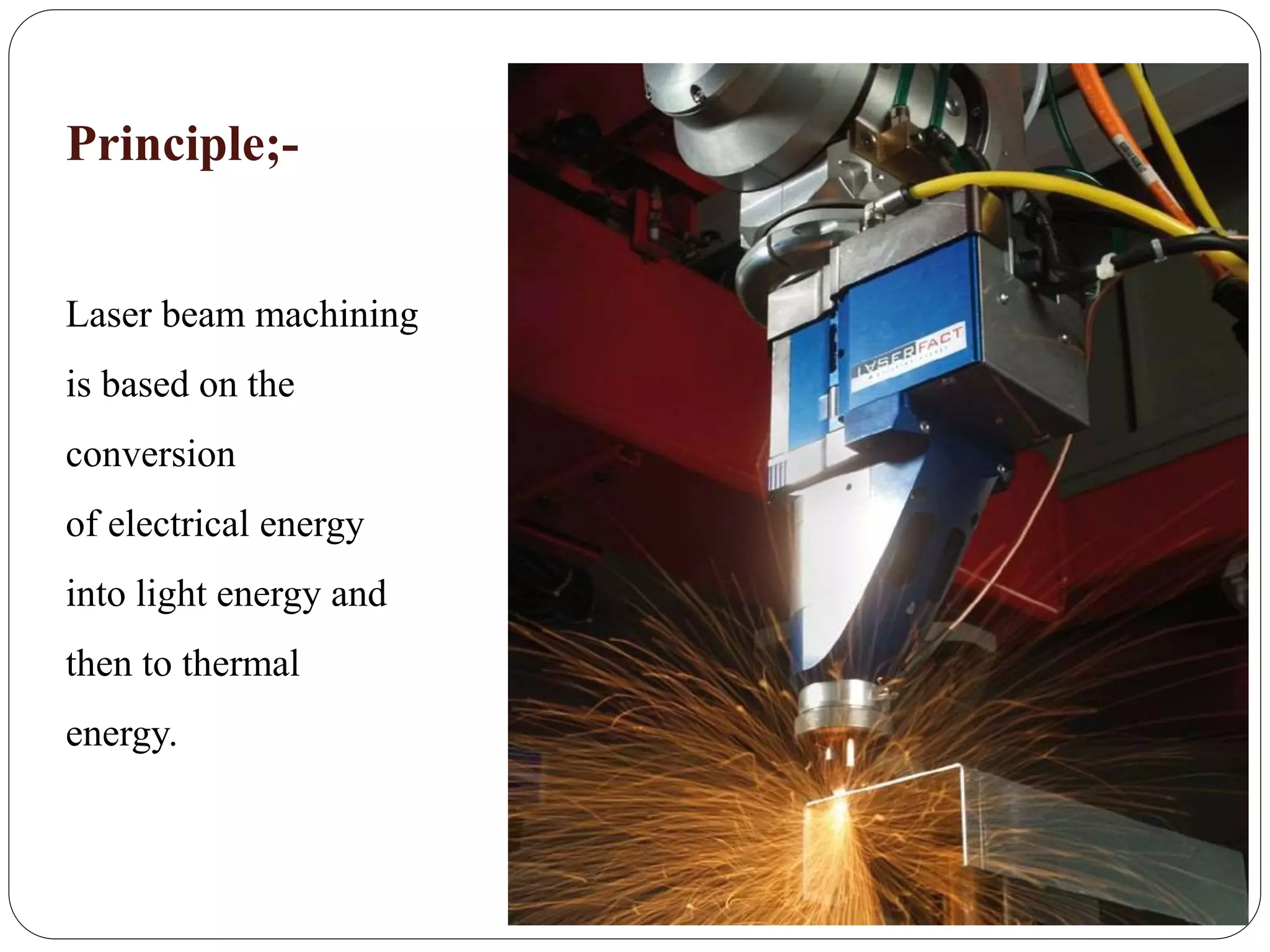

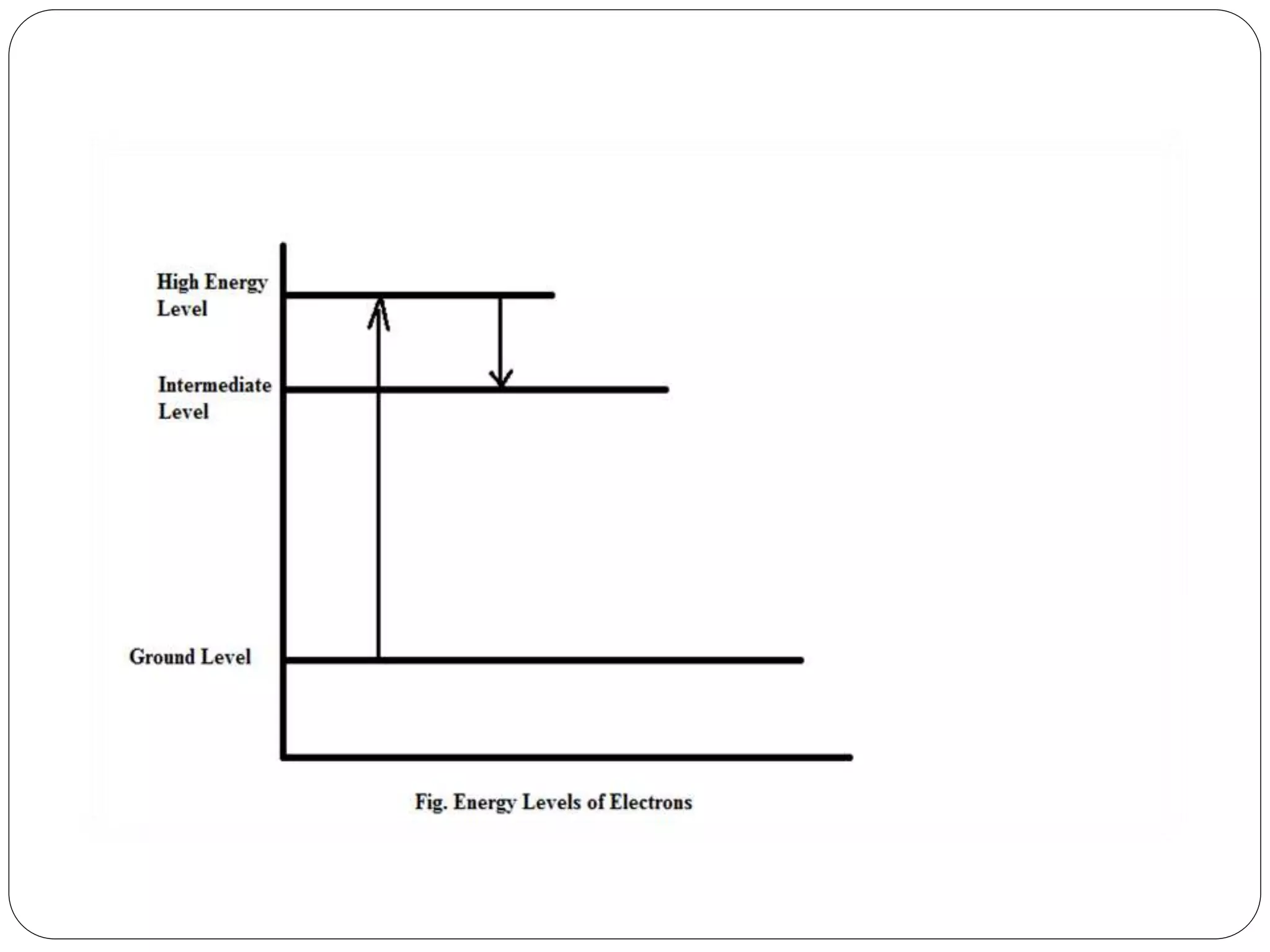

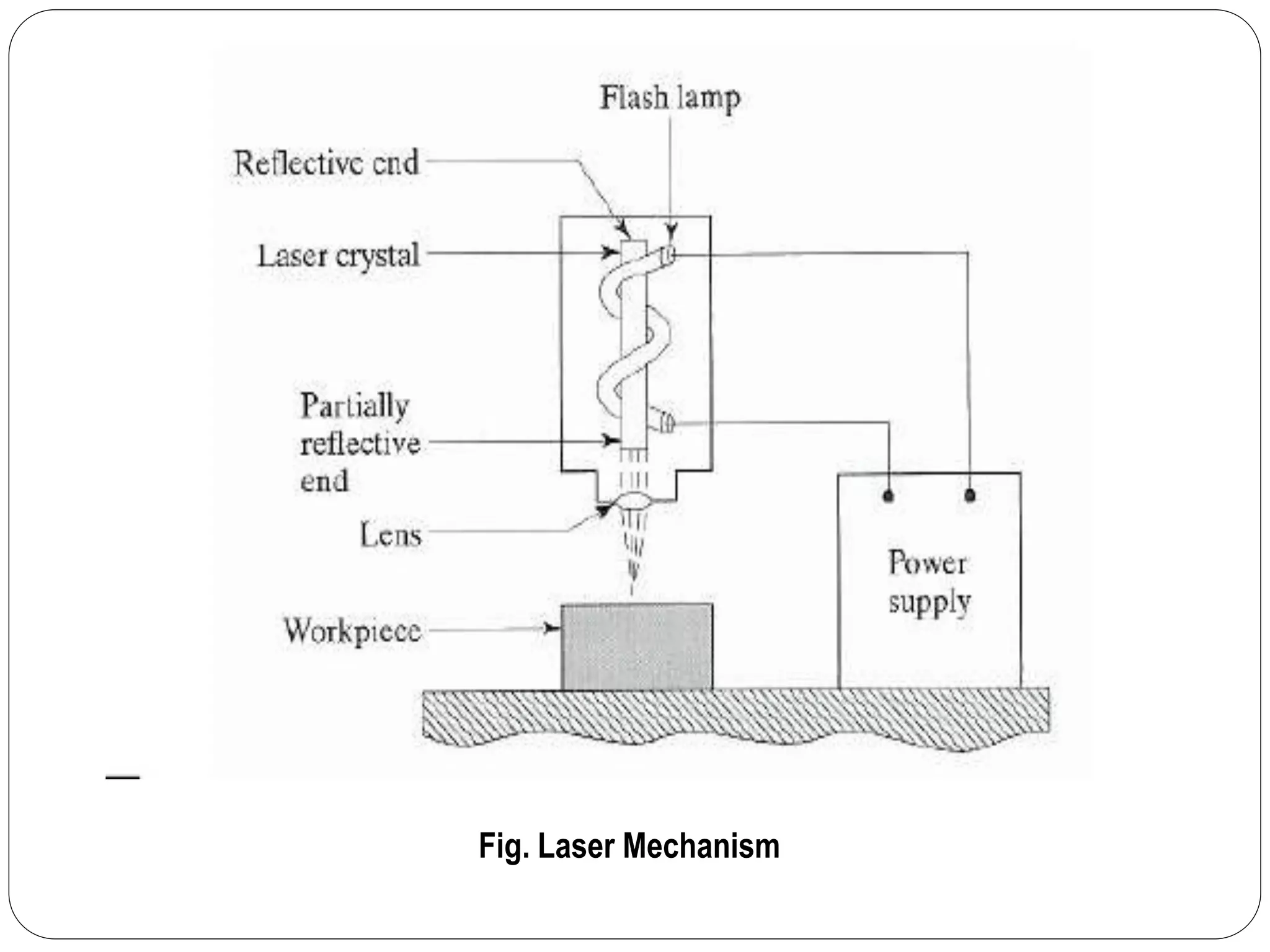

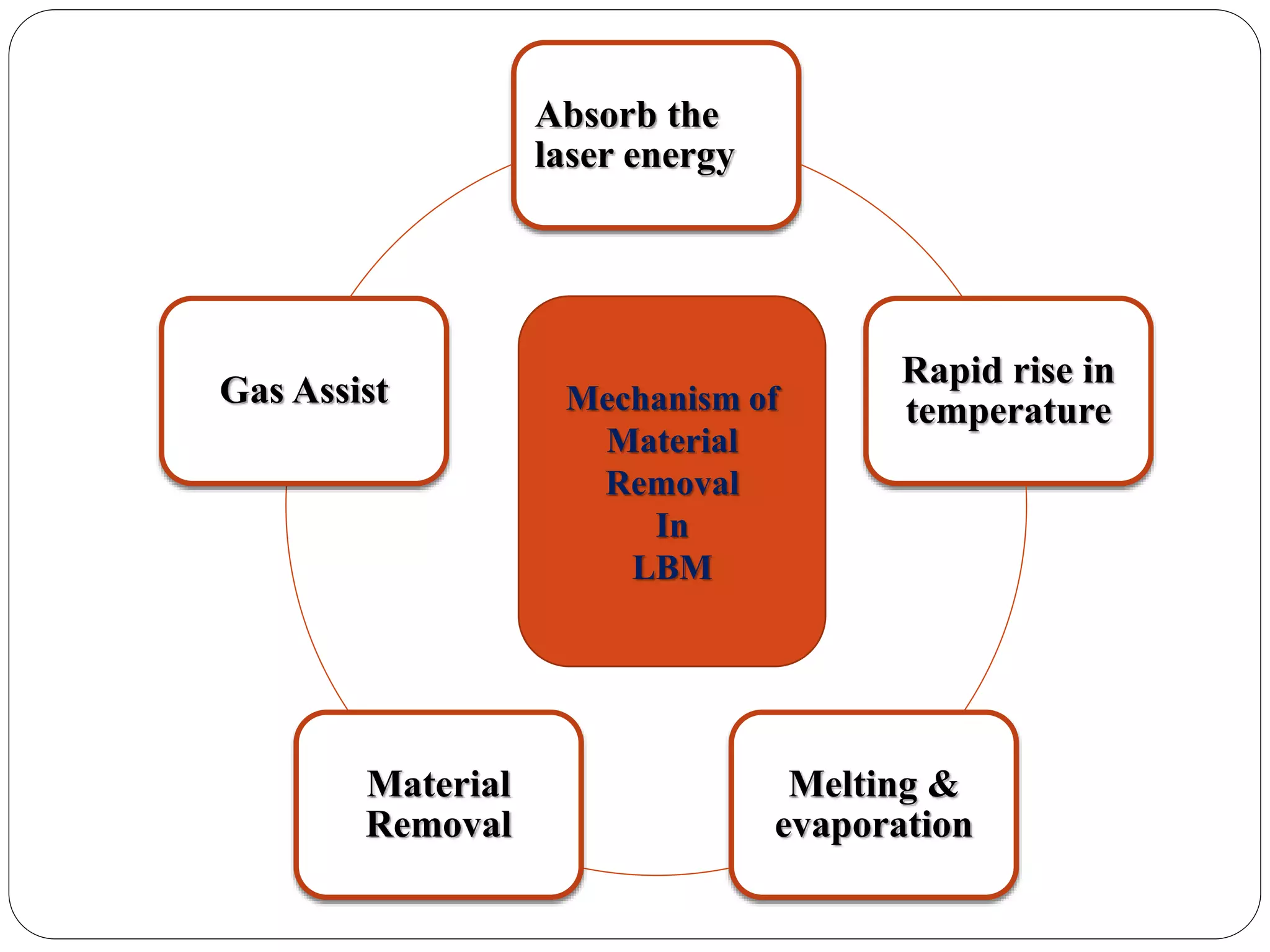

The document discusses laser beam machining (LBM), a nontraditional thermal processing technique that uses lasers for material removal by melting or vaporizing it. It outlines the principles of laser operation, the LBM process, advantages such as precision and speed, and disadvantages including thermal issues and energy costs. LBM proves effective for various materials, though it has limitations with certain metals and transparent materials.