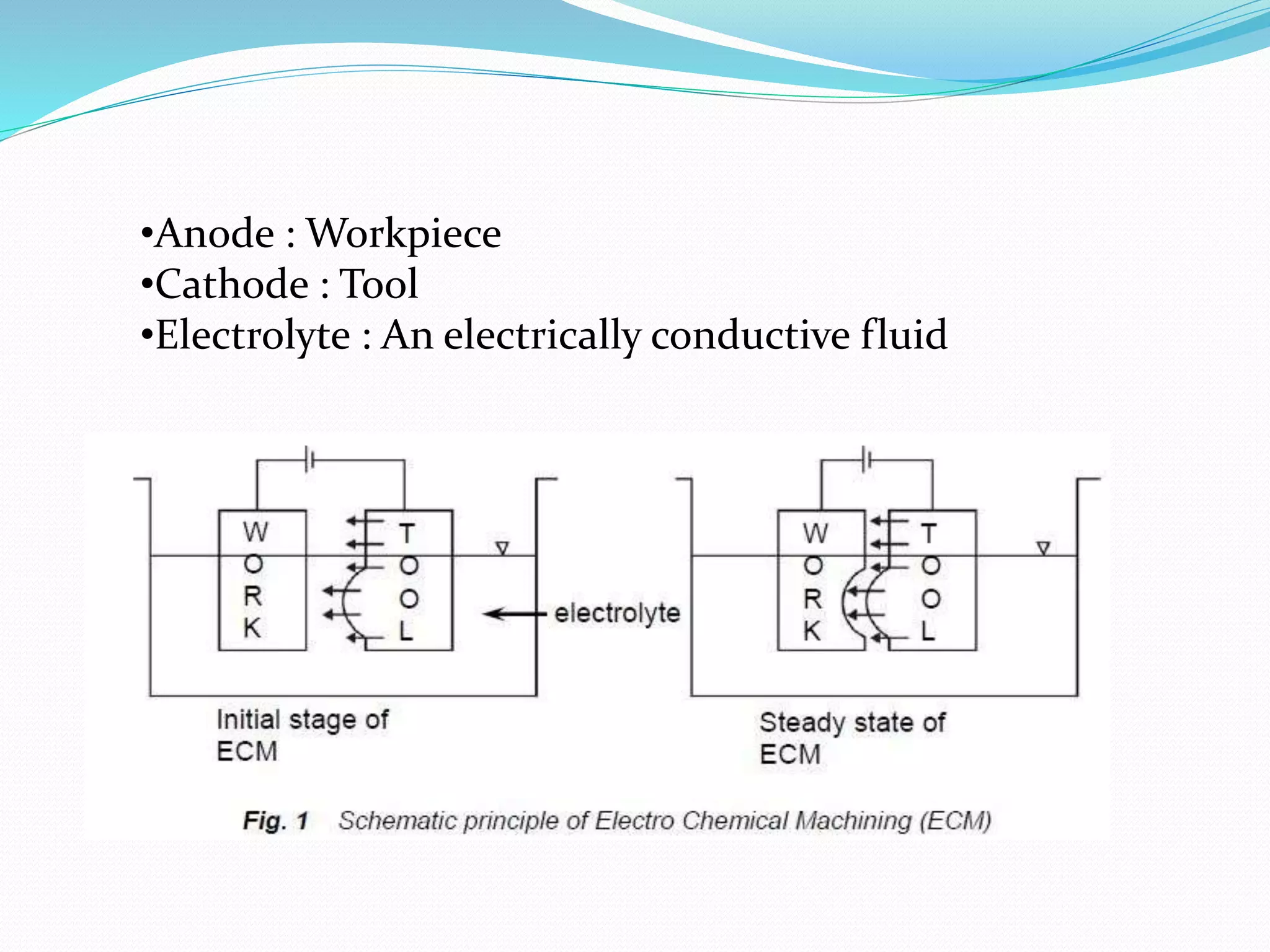

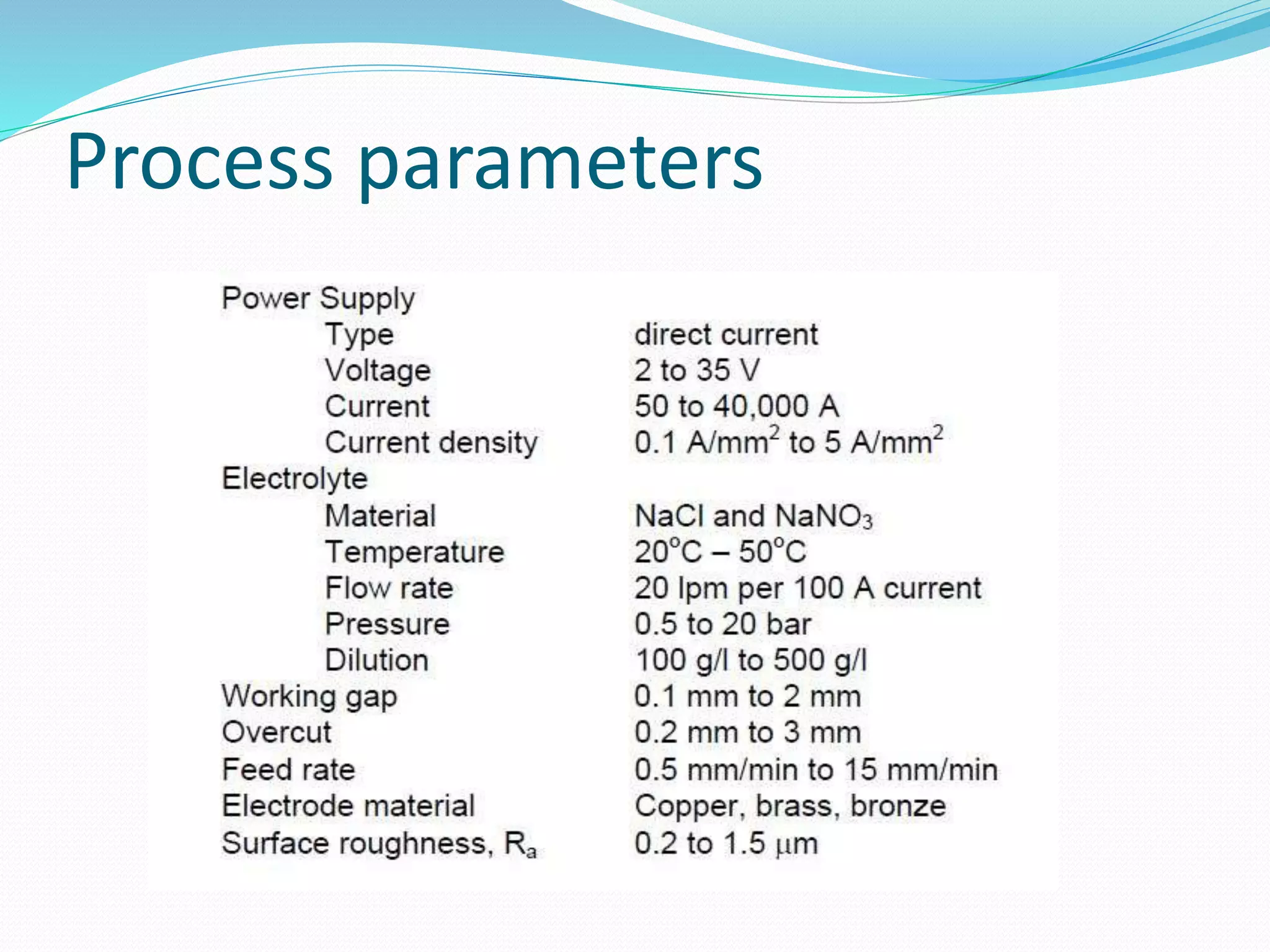

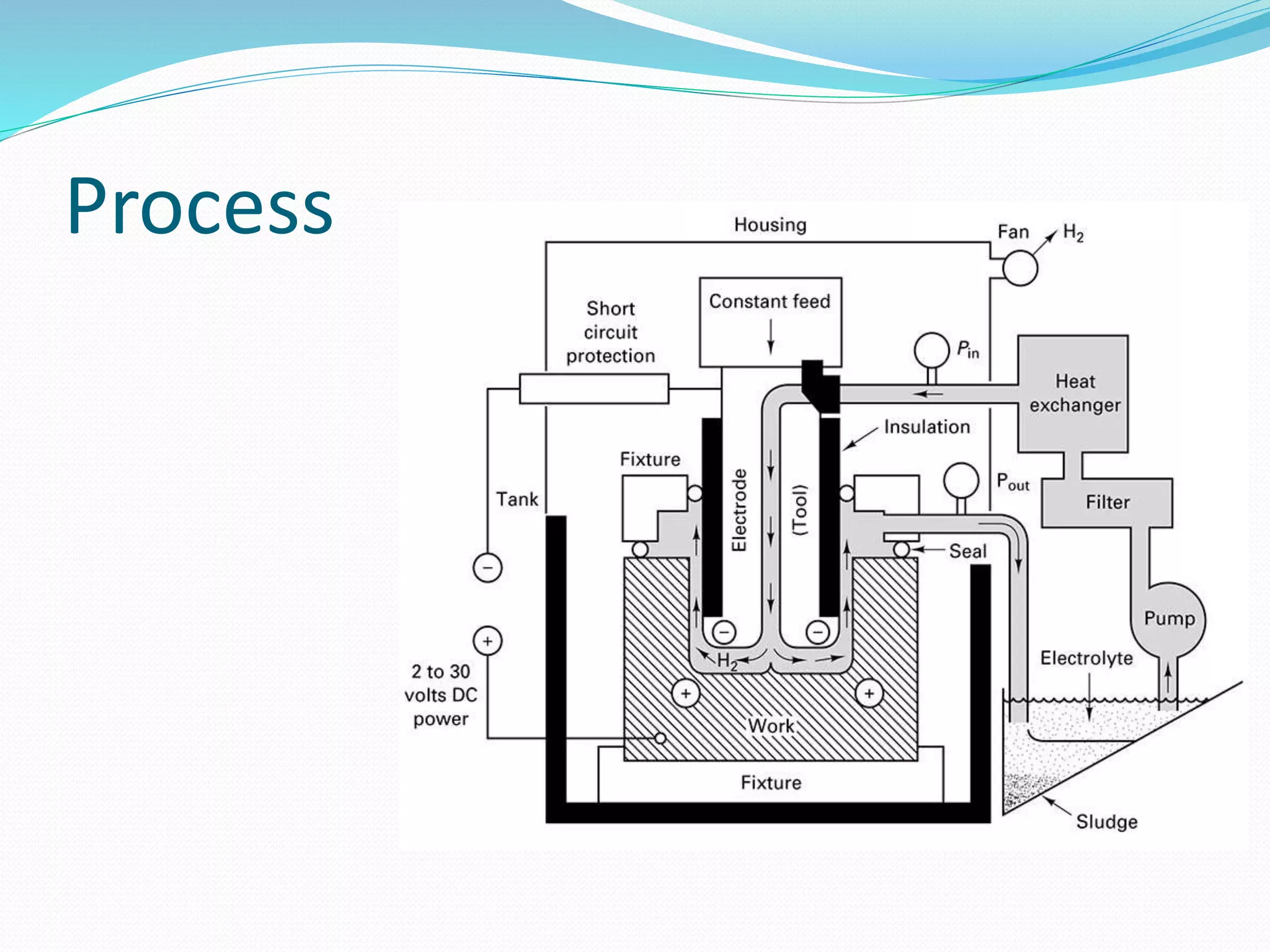

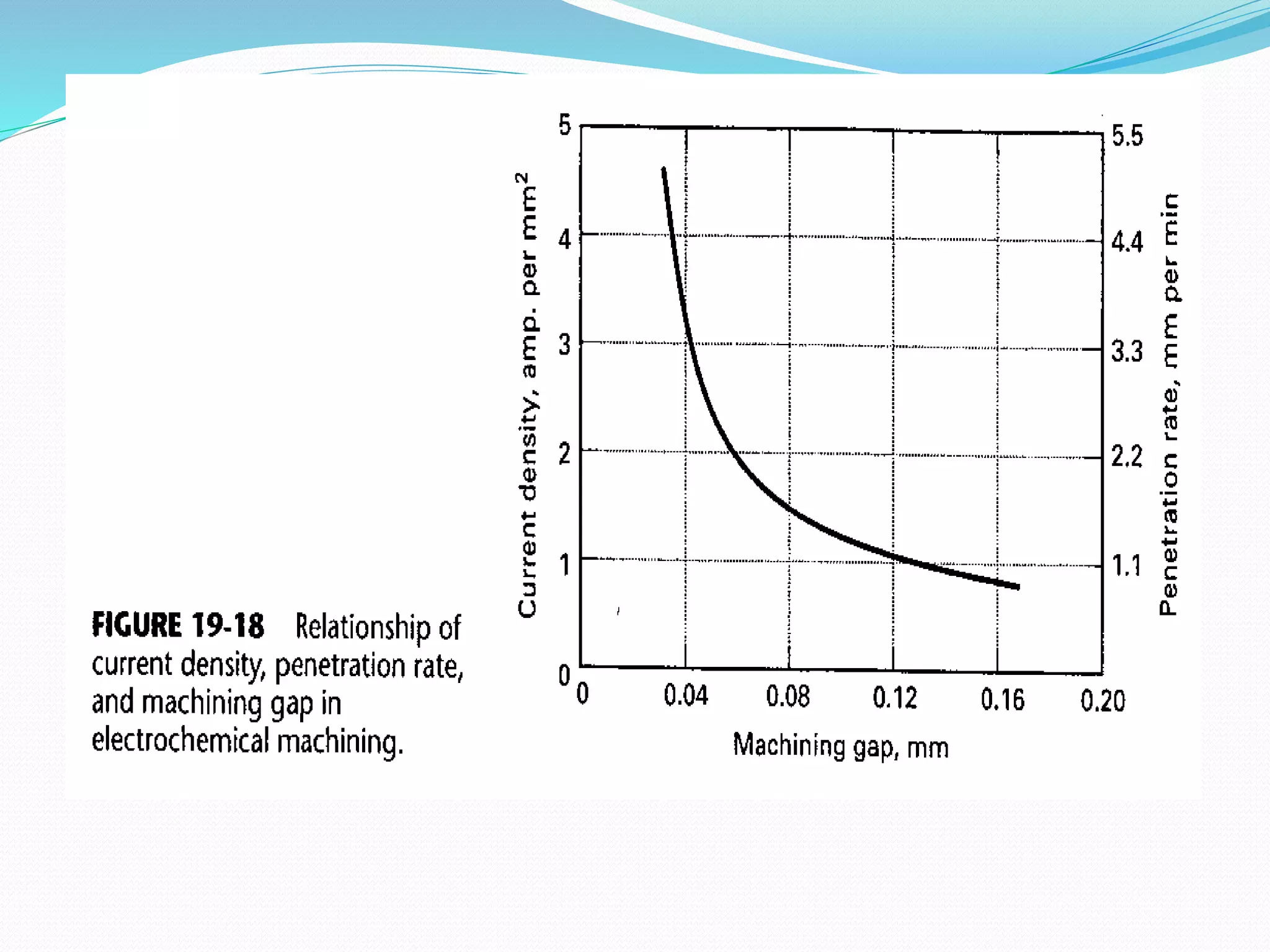

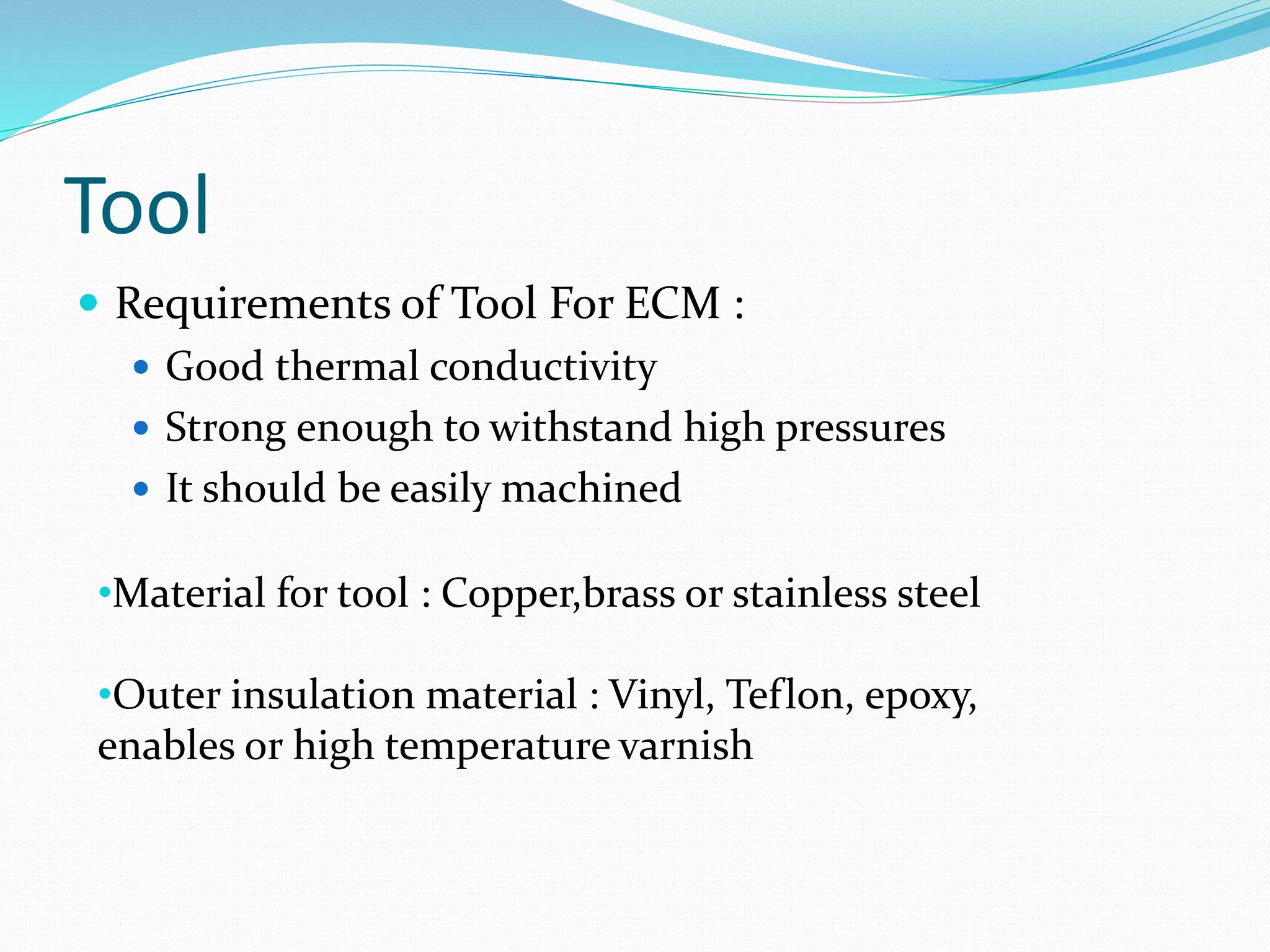

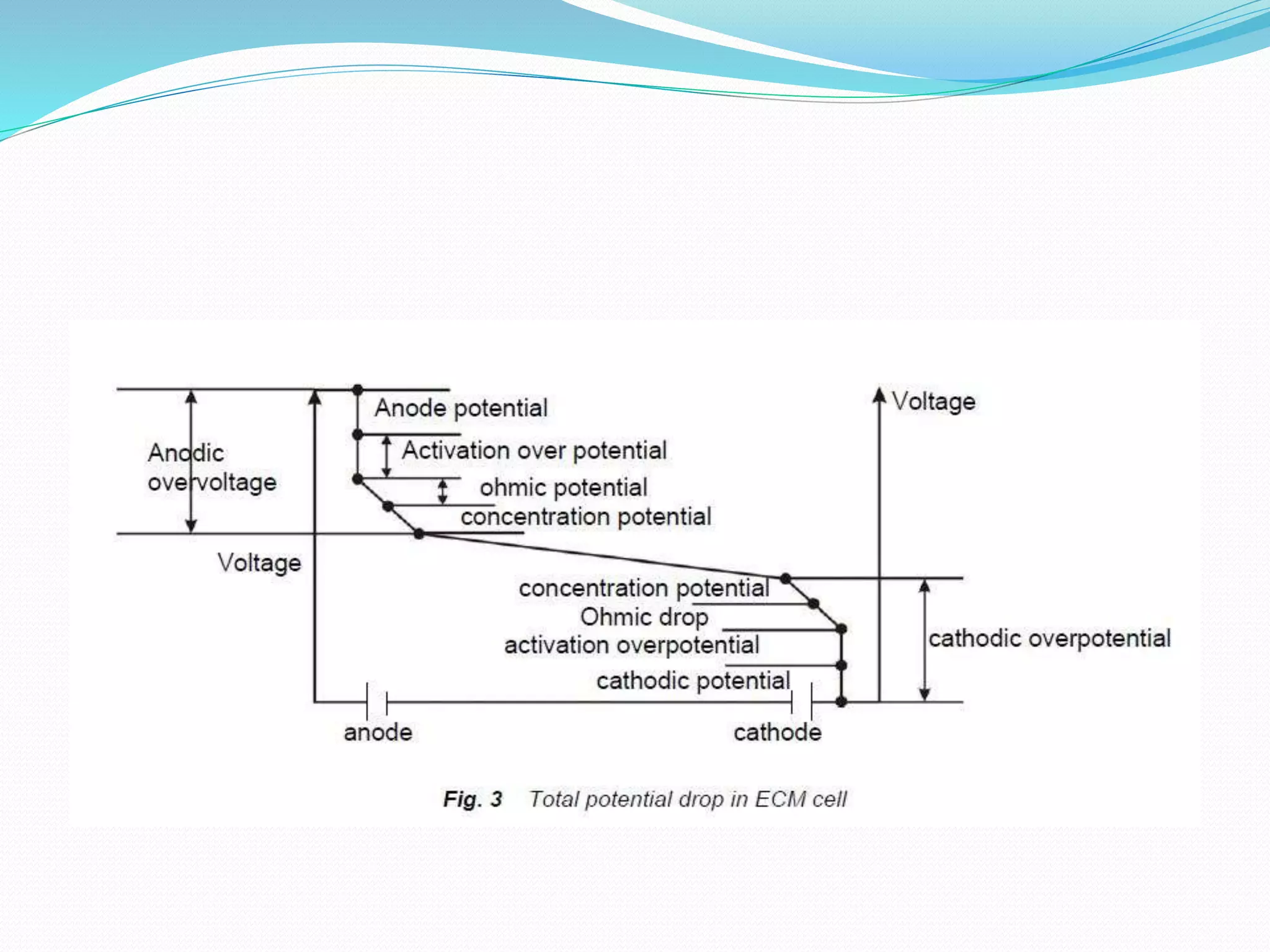

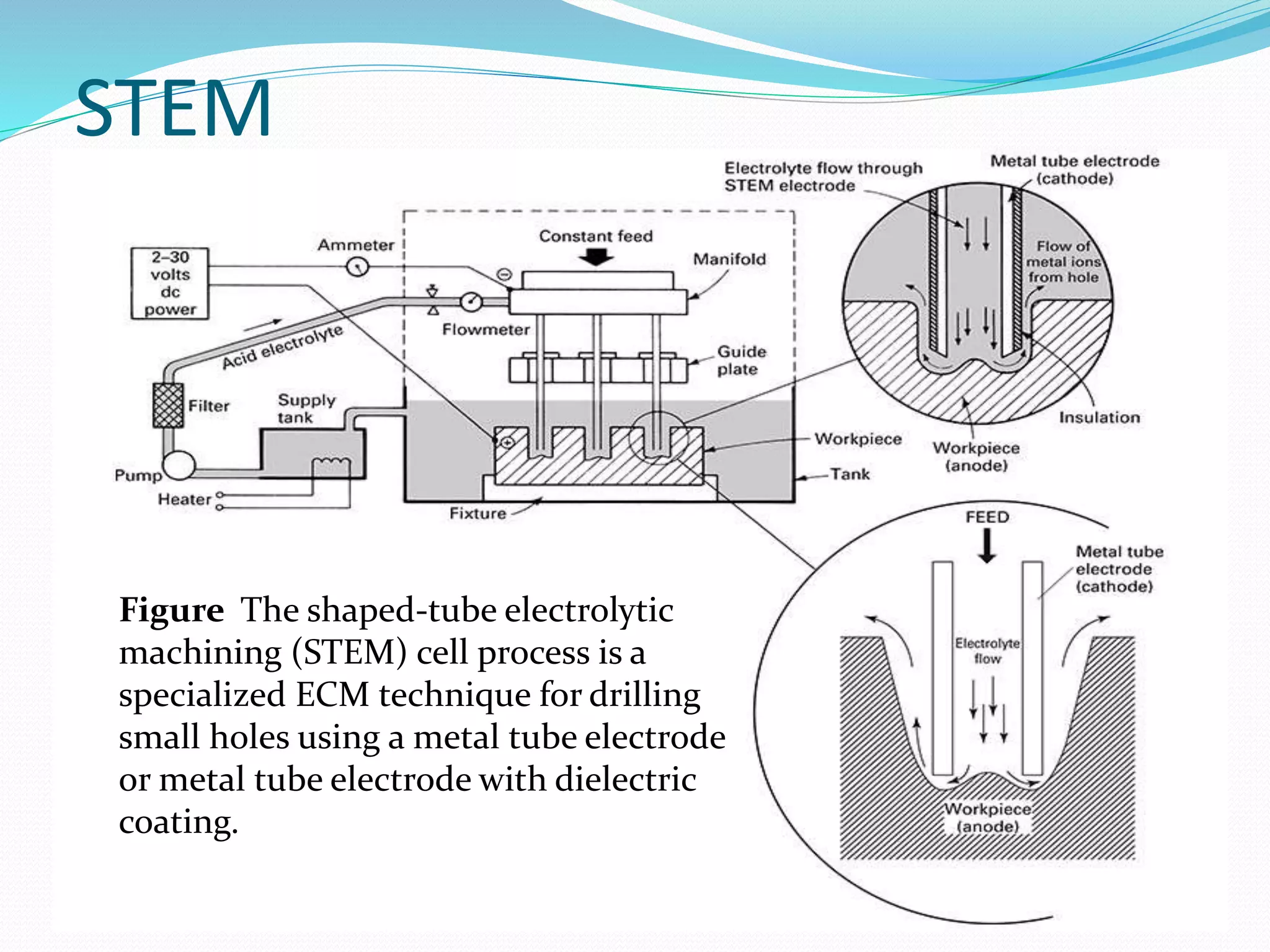

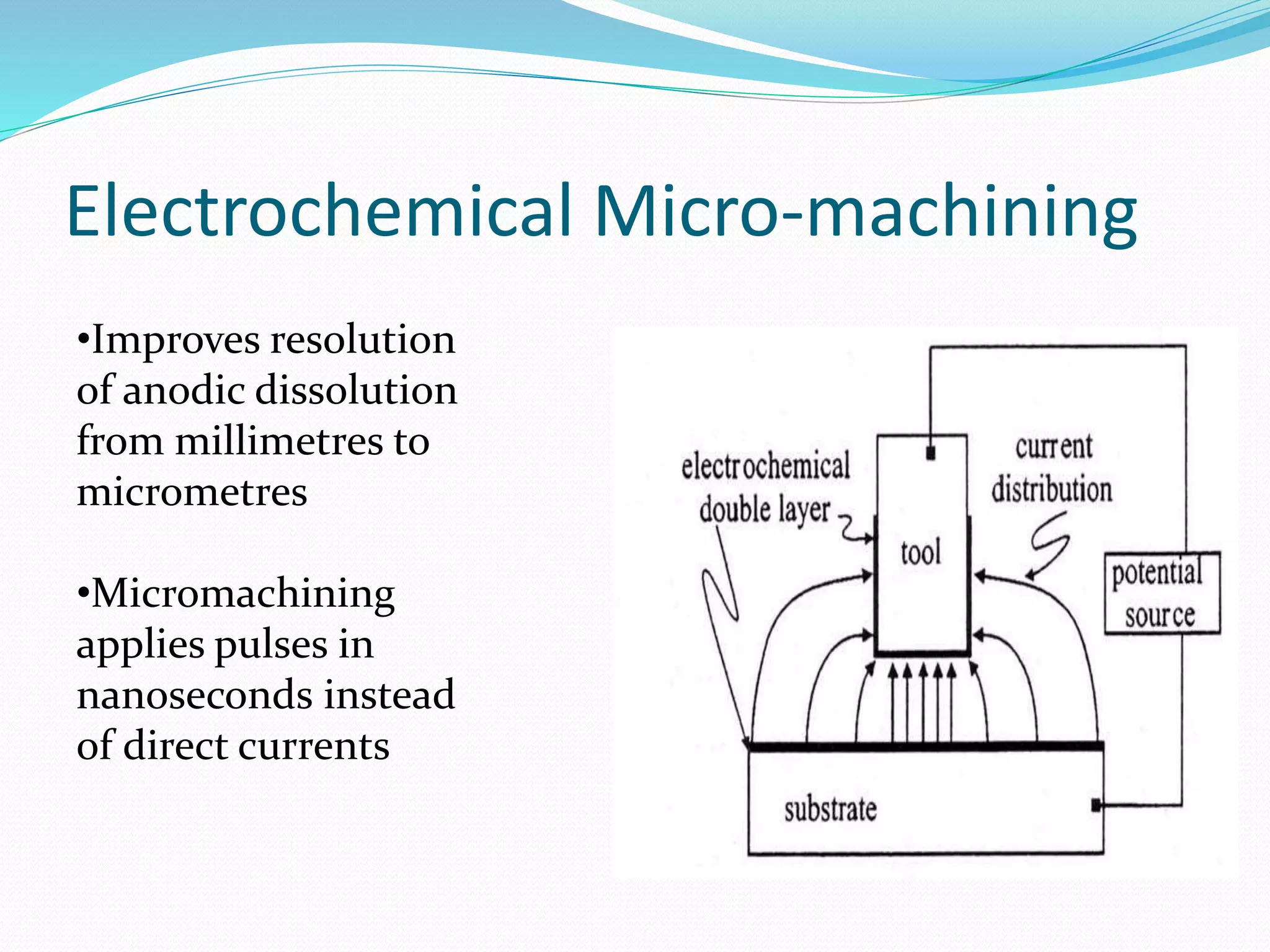

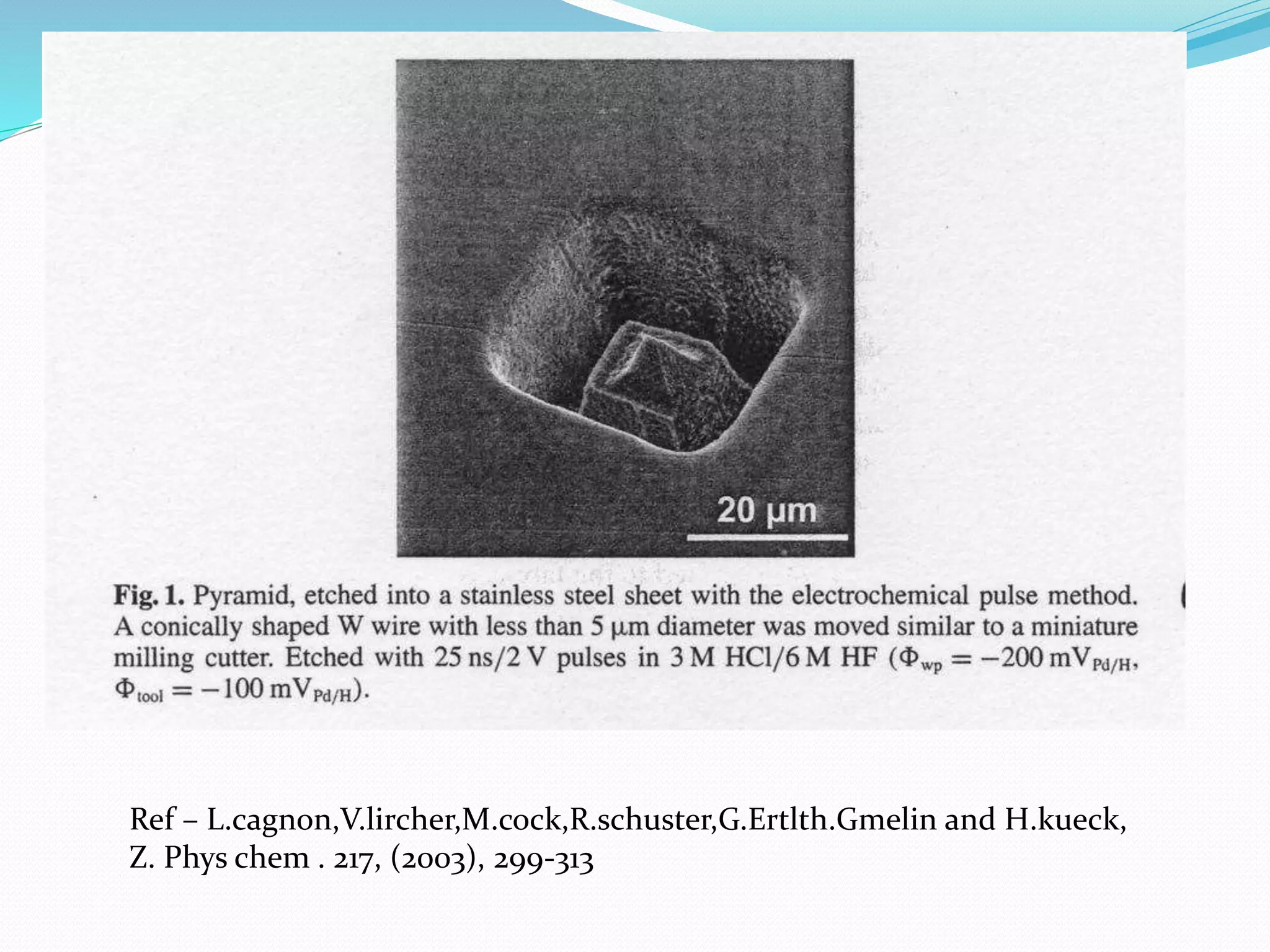

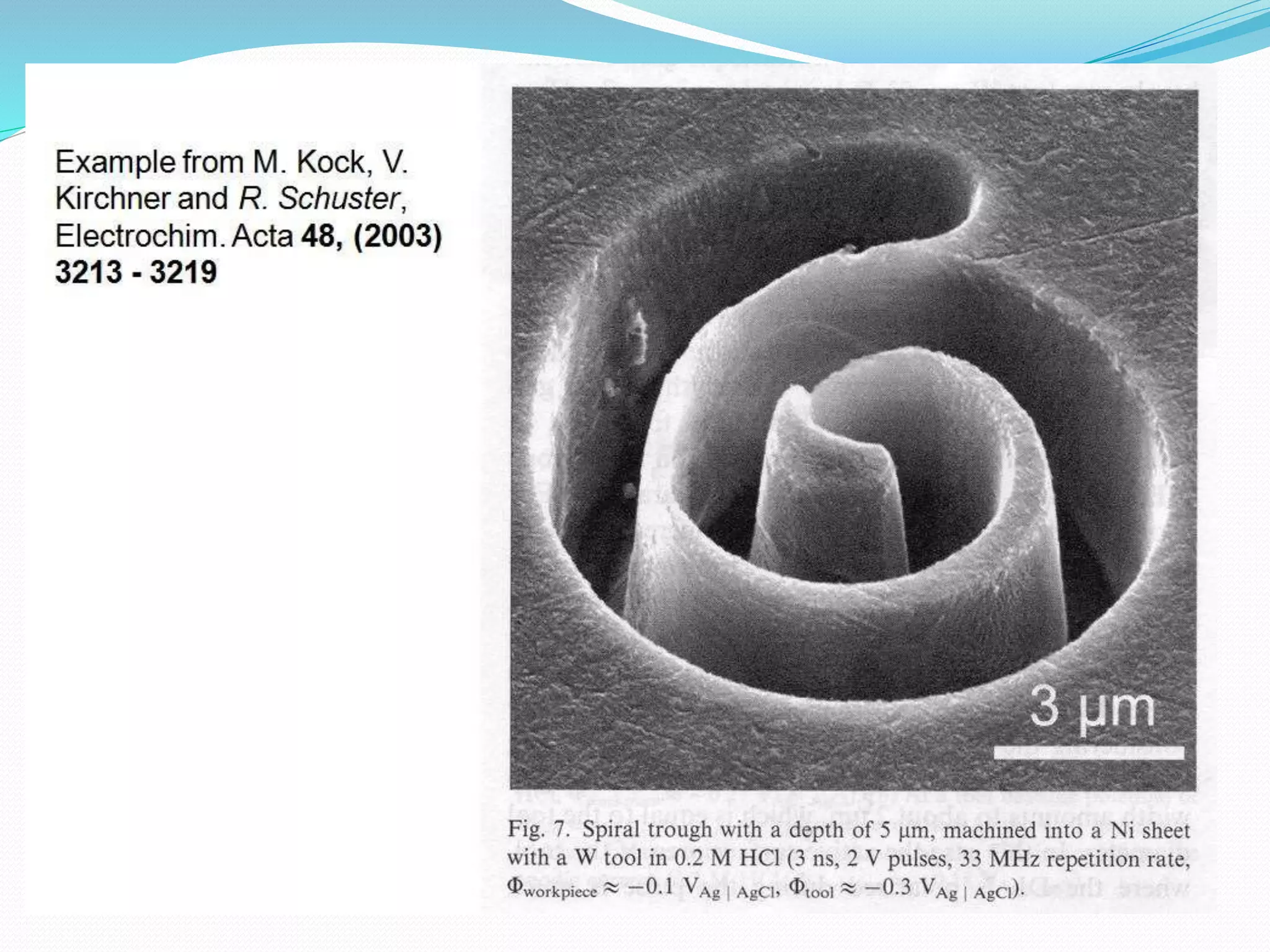

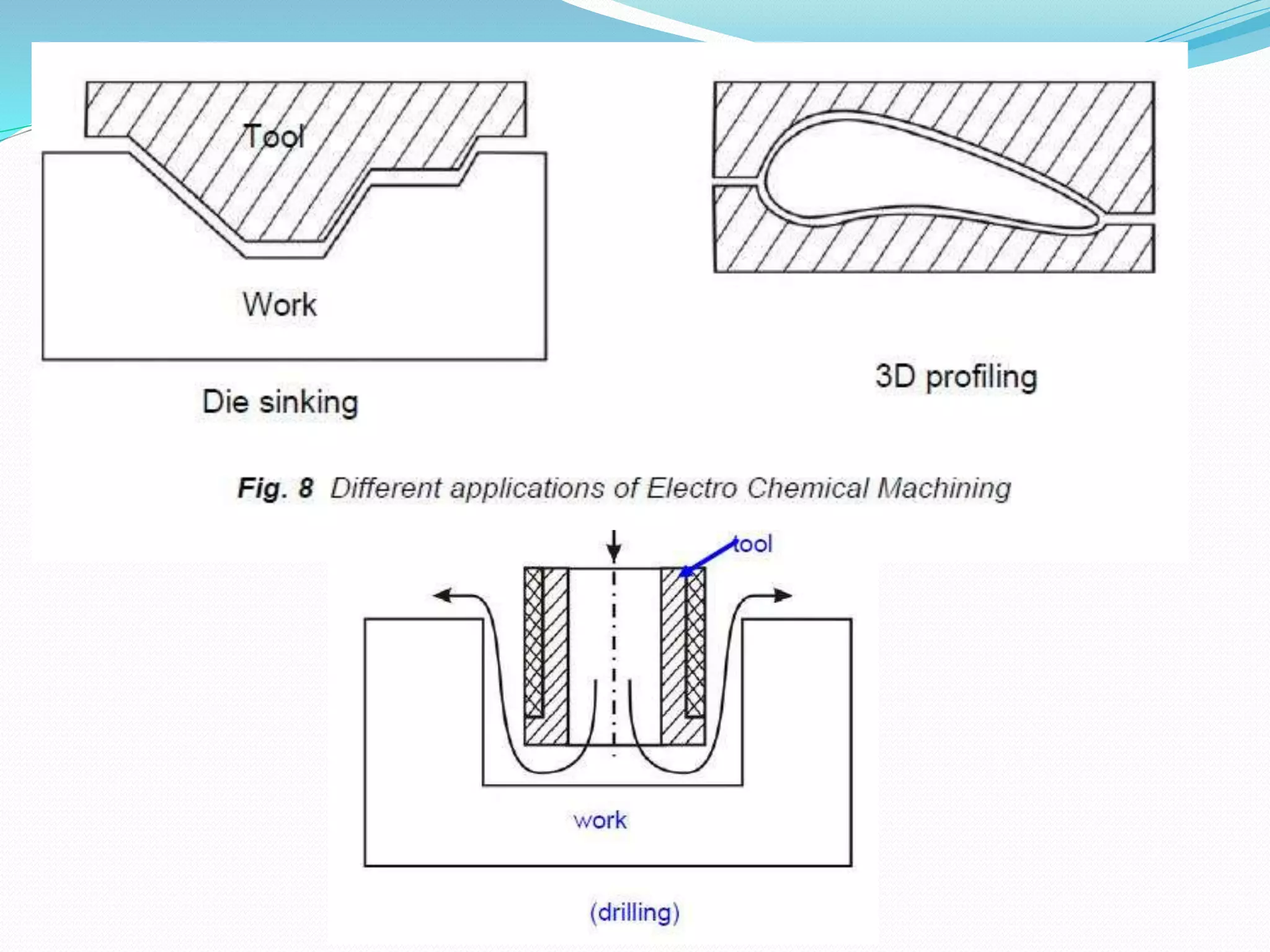

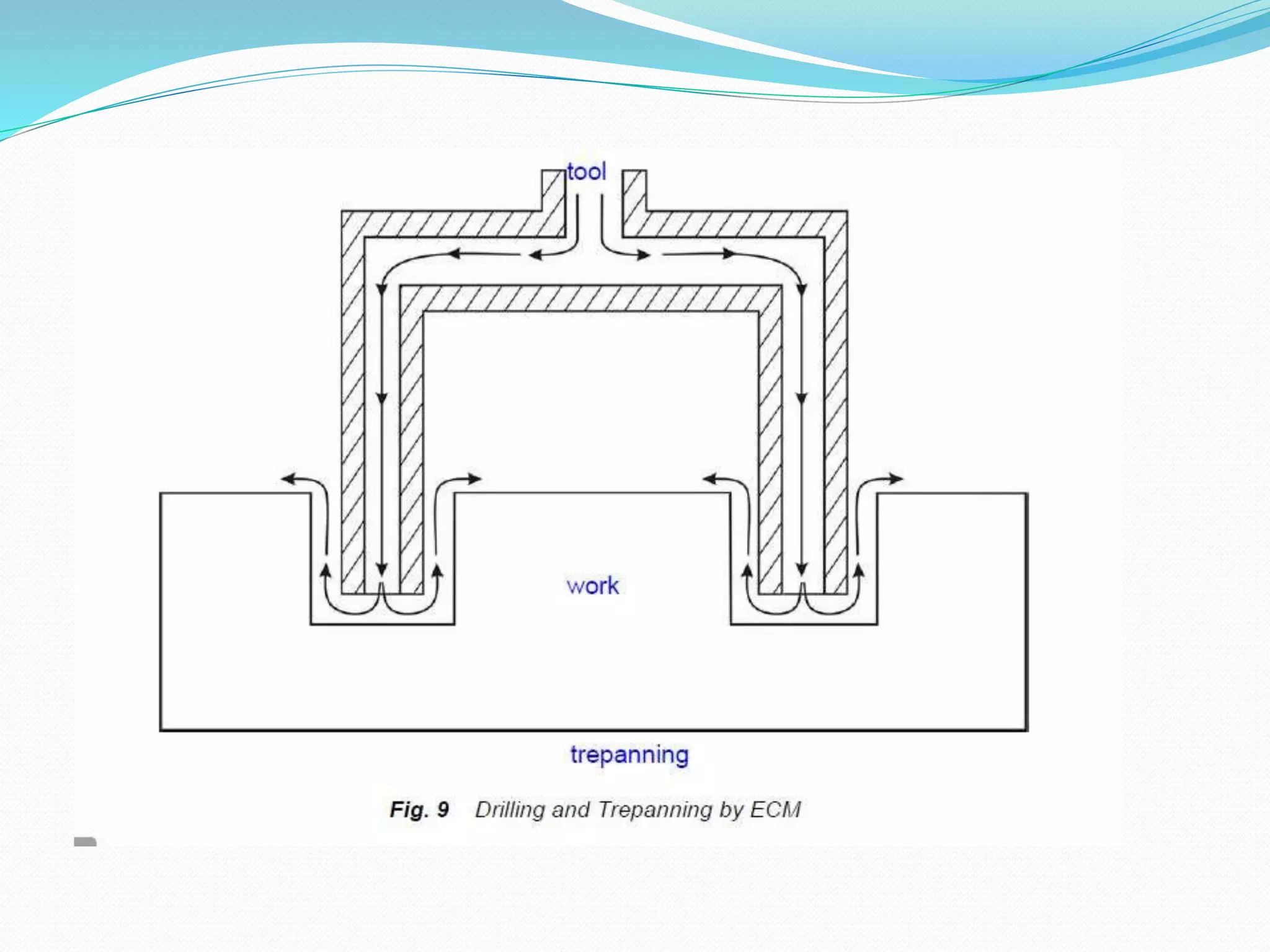

The document discusses electrochemical machining (ECM), a non-conventional machining process that removes metal through an electrochemical reaction, functioning like 'reverse electroplating.' It highlights the principles of operation, including Faraday's law, as well as the essential components such as power supply, electrolyte, and tools used in the process. ECM is particularly beneficial for mass production of complex geometries and difficult-to-machine materials, offering advantages like high precision and minimal tool wear, albeit with some environmental concerns and high initial costs.