Induction hardening is an efficient surface hardening process that uses electromagnetic induction to generate eddy currents and rapidly heat metal components. It produces a martensitic microstructure upon quenching that increases hardness, strength, and wear resistance while minimizing distortion compared to traditional furnace treatments. Induction hardening takes less than a minute, whereas nitriding and carburizing can take hours, and it induces higher compressive residual stresses in the surface.

![Popular Hardening Treatments*

Flame hardening (~50 HRC) (a) (b)

Only for gray cast iron

Anneals core material during process

Nitriding (~69 HRC)

Uses ammonia or cyanide salt baths Images of gear teeth hardened by (a)

nitriding and (b) carburizing taken from

Depth of 1 mm

http://www.gearsolutions.com/media//uplo

Roughly 4 hours per work piece ads/assets//PDF/Articles/Jan_10/0110_Boeing

.pdf

Carburizing (~50 HRC)

Used on low carbon content steel

(<0.2%C) Need more efficient

Depth up to 6 mm process with required

Typically 12-72 hrs. per work piece product properties with

shorter process time!

3

*Davis, et. al, Surface Engineering of Cast Irons, Surface Engineering, ASM Handbook [5] 683-700 (1994)](https://image.slidesharecdn.com/inductionhardeningashleylane-1347397922344-phpapp01-120911161328-phpapp01/75/Induction-Hardening-3-2048.jpg)

![Why Choose Induction?

Produces ideal properties

Hardness (~67 HRC)

Strength and wear resistance of part

Has much faster heating rate than traditional furnace

treatments

Provides for more control over outcome

Less distortion of work piece*

Warpage is roughly 0.03mm compared to 0.3mm from furnace treatments*

Heating can be localized for surface hardening

Allows the core metal to be unaffected

Creates higher residual stresses

4

*Rudnev, Simulation of Induction Heat Treating, Metals Process Simulation, ASM Handbook, [22B]501–546 (2009).](https://image.slidesharecdn.com/inductionhardeningashleylane-1347397922344-phpapp01-120911161328-phpapp01/75/Induction-Hardening-4-2048.jpg)

![Induction Hardening

Heat treatment used for metal

(typically steel)

Uses electromagnetic induction*

Eddy currents are generated in

metal

Resistive heating is proportional to

resistance in metal and currents

produced

Hardening may be done on the

surface or throughout entire work Image of hardened gear teeth taken

piece from

http://www.ersengine.com/gains-

Utilizes localized heating

ground-through-advances-in-

Does not affect properties of the technology/.

part as a whole

5

*Rudnev, Simulation of Induction Heat Treating, Metals Process Simulation, ASM Handbook, [22B]501–546 (2009).](https://image.slidesharecdn.com/inductionhardeningashleylane-1347397922344-phpapp01-120911161328-phpapp01/75/Induction-Hardening-5-2048.jpg)

![Currents and Magnetic Field

Eddy currents

Current induced in conductors

when exposed to a

changing magnetic field

Due to variations of the field with

time

Generates resistive heating in metal

Can reaustenitize metal in 0.5 s*

Induced as result of Faraday’s law

of induction*

𝑑Φ

𝑒 = −𝑁 Image of currents and magnetic field

𝑑𝑡 induced during hardening process.*

e =induced voltage

N=number of coil turns

Φ= magnetic field

6

*Hassell, et. al, Induction Heat Treating of Steel, Heat Treating, ASM Handbook [4] 164–202 (1991).](https://image.slidesharecdn.com/inductionhardeningashleylane-1347397922344-phpapp01-120911161328-phpapp01/75/Induction-Hardening-6-2048.jpg)

![Electrical Properties of Steel

Only adjustable parameter is the

frequency

High frequencies are used for

surface hardening

Frequency (kHz)

Lower frequencies are used for

through-hardening

ρ

𝑑=

πμ0 μ f

d=depth of hardening

ρ= resistivity Diameter (mm)

μ0= 4π×10−7 V·s/(A·m) (magnetic permeability of vacuum)

μ =magnetic permeability of part Plot of diameter versus frequency in

f=frequency of magnetic field plain carbon steel.*

7

*Hassell, et. al, Induction Heat Treating of Steel, Heat Treating, ASM Handbook [4] 164–202 (1991).](https://image.slidesharecdn.com/inductionhardeningashleylane-1347397922344-phpapp01-120911161328-phpapp01/75/Induction-Hardening-7-2048.jpg)

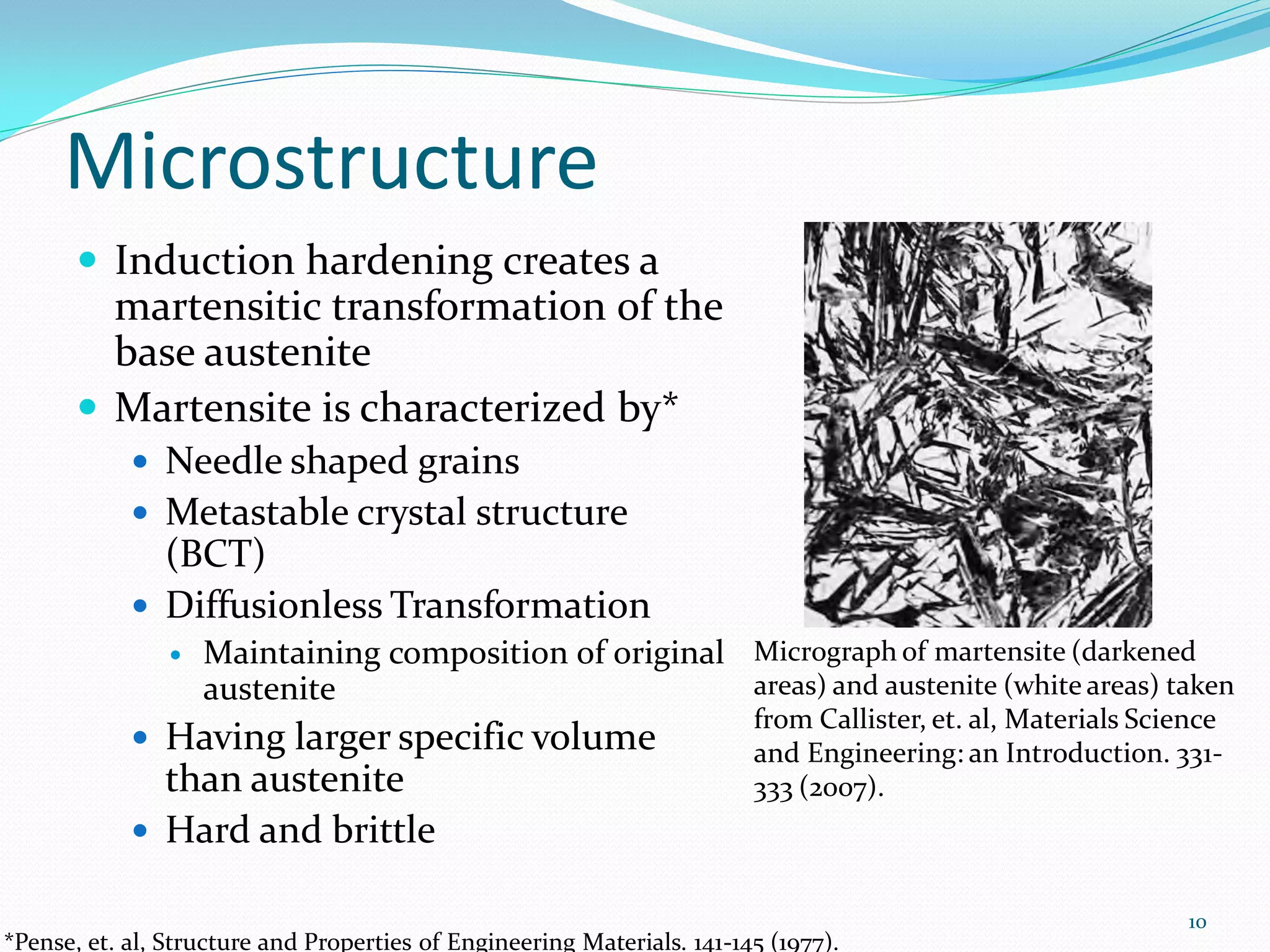

![Microstructural Relations

Hardness of austenitized

parts depends mainly on

chemical composition

and quench medium*

Desired Microstructures

for reaustenization*

Finer bainite and

martensite> pearlite>

Effect of carbon on hardness in plain carbon

spheroidite steels for (A) induction hardening, (B) furnace

hardening with water quench and (C) furnace

hardening with water quench and temper. The

quenched-and-tempered steels were treated in

liquid nitrogen following water quenching

prior to tempering at 100 °C for 2 hrs.*

11

*Hassell, et. al, Induction Heat Treating of Steel, Heat Treating, ASM Handbook [4] 164–202 (1991).](https://image.slidesharecdn.com/inductionhardeningashleylane-1347397922344-phpapp01-120911161328-phpapp01/75/Induction-Hardening-11-2048.jpg)

![Induced Stresses

Treatment induces compressive

stresses at surface (>205 Mpa)*

Surface has volume expansion

Non-treated core remains

unchanged

Martensite retains residual

stresses**

Typical hardness and residual stress profile of

Image of gear teeth being heated taken from

induced-hardened steels using general

http://www.ersengine.com/gains-ground-through-

dissection method. **

advances-in-technology/.

*Sinha, et. al, Defects and Distortion in Heat-Treated Parts, Heat Treating, ASM Handbook [4] 601-619 (1991). 12

**Davis, et. al, Surface Engineering of Cast Irons, Surface Engineering, ASM Handbook [5] 683-700 (1994)](https://image.slidesharecdn.com/inductionhardeningashleylane-1347397922344-phpapp01-120911161328-phpapp01/75/Induction-Hardening-12-2048.jpg)

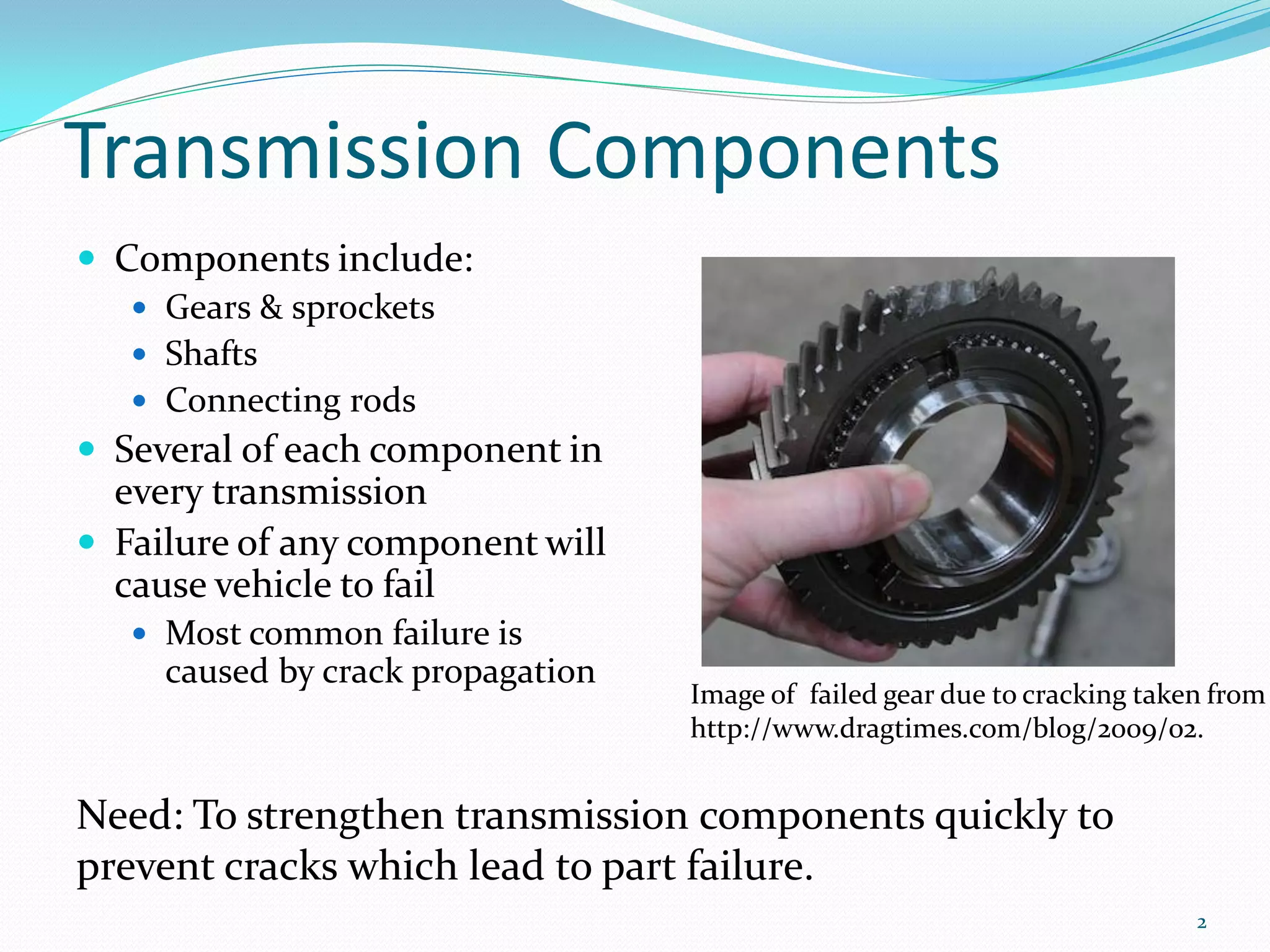

![Maximum Residual Stresses in

Surface-treated Steel*

Heat treatment Residual Stress (MPa)

Carburized and quenched 340

Nitrided to case depth of about 0.5

600

mm (0.02 in.)

Induction hardened, untempered 1000

Stress measurements taken at 0.05mm from surface

13

*Sinha, et. al, Defects and Distortion in Heat-Treated Parts, Heat Treating, ASM Handbook [4] 601-619 (1991).](https://image.slidesharecdn.com/inductionhardeningashleylane-1347397922344-phpapp01-120911161328-phpapp01/75/Induction-Hardening-13-2048.jpg)

![Review of Surface Hardening *

Induction hardening (~67 HRC) (a)

(b)

Can be used on any type of steel

Utilizes localized heating

Has clean transition pattern

Process takes less than 1 minute

Nitriding (~69 HRC) (c)

Uses ammonia or cyanide salt baths

Depth of 1 mm

Roughly 4 hours per work piece

Carburizing (~50 HRC)

Images of gear teeth hardened by (a)

Used on low carbon content steel nitriding (b) carburizing and (c) induction

(<0.2%C) hardening found at

http://www.gearsolutions.com/media//uplo

Depth up to 6 mm

ads/assets//PDF/Articles/Jan_10/0110_Boeing

Typically 12-72 hrs. per work piece .pdf

14

*Davis, et. al, Surface Engineering of Cast Irons, Surface Engineering, ASM Handbook [5] 683-700 (1994)](https://image.slidesharecdn.com/inductionhardeningashleylane-1347397922344-phpapp01-120911161328-phpapp01/75/Induction-Hardening-14-2048.jpg)