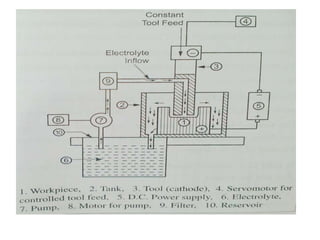

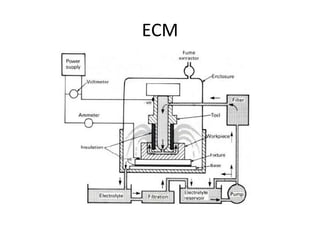

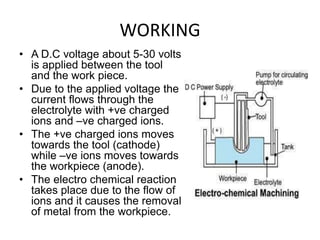

Electrochemical machining (ECM) is a non-traditional machining process that removes metal by electrolysis rather than mechanical forces. In ECM, a tool acts as a cathode and the workpiece as an anode, and an electric current is passed through an electrolyte in the gap between them, chemically dissolving metal from the workpiece. ECM can machine hard metals and complex shapes more accurately than traditional machining. It provides a smooth surface finish with no mechanical forces or heat affecting the workpiece material. However, ECM requires an electrolyte solution, specialized equipment, and produces chemical waste, making it more expensive and less environmentally friendly than other processes.