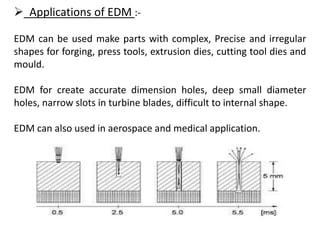

Electrical discharge machining (EDM) is an unconventional machining process that uses electrical sparks to erode unwanted material from a workpiece by discharging electricity between an electrode tool and the workpiece, separated by a dielectric fluid. EDM can machine hard materials and complex shapes by using individual sparks that briefly heat the material to plasma temperatures without direct contact. The process works by concentrating electrons and ions in the dielectric fluid gap between the tool and workpiece, causing sparks that thermally erode unwanted material. EDM enables precision machining of difficult shapes for aerospace and medical applications but has low material removal rates and leaves a rough surface finish.

![Subject – Production Technology

Topic - Electrical Discharge Machining [EDM]

Presented By :- Dhruv Shah](https://image.slidesharecdn.com/electricaldischargemachiningedm-170803232011/85/Electrical-discharge-machining-EDM-1-320.jpg)

![Electrical Discharge Machining [EDM]

Electrical discharge machining process is also known

as thermal erosion, electro erosion or spark erosion

machining. EDM is one of the most widely used

unconventional machining process. The main attraction

of EDM is that this technique utilizes thermoelectric

process to erode undesirable materials from the w/p by a

series of discrete electrical sparks between the w/p and

the electrode.](https://image.slidesharecdn.com/electricaldischargemachiningedm-170803232011/85/Electrical-discharge-machining-EDM-2-320.jpg)

![Figure of Electrical Discharge Machining [EDM]](https://image.slidesharecdn.com/electricaldischargemachiningedm-170803232011/85/Electrical-discharge-machining-EDM-3-320.jpg)

![Electrical discharge machining [EDM]](https://image.slidesharecdn.com/electricaldischargemachiningedm-170803232011/85/Electrical-discharge-machining-EDM-10-320.jpg)