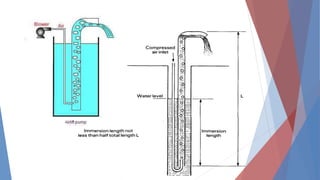

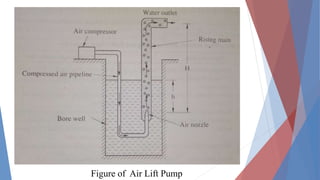

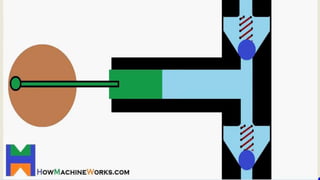

The document discusses an air lift pump, which uses compressed air to lift water from deep wells or sumps. It has no moving parts submerged in water. The air lift pump works by injecting compressed air through nozzles into the bottom of a delivery pipe submerged in the water. This causes the air-water mixture in the pipe to become less dense than the surrounding water, rising up the pipe and discharging water at the top. While requiring no submerged parts and able to lift water through narrow boreholes, air lift pumps have low efficiency, limited flow rates, and cannot operate if the water level drops below a certain point. They are often used in deep, dirty wells to avoid clogging mechanical pumps.