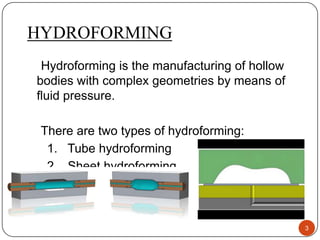

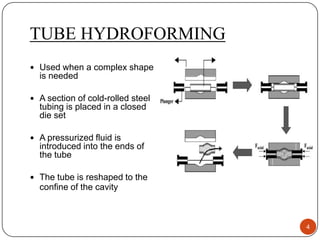

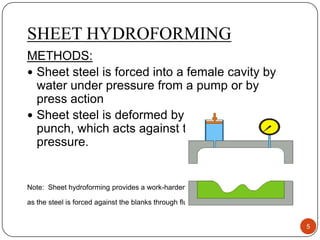

Hydroforming is a manufacturing process that uses fluid pressure to form hollow metal parts with complex geometries. There are two types: tube hydroforming uses pressurized fluid to reshape tubing inside a die, while sheet hydroforming forces sheet metal into a die cavity using fluid or press action. Hydroforming is used in automotive, sanitary, and aerospace applications to create parts with tight tolerances, fewer welds, and reduced weight. Design considerations include part geometry, material properties, die design, and pressure capabilities. Hydroforming allows for innovative part designs but has high equipment costs and slow cycle times.