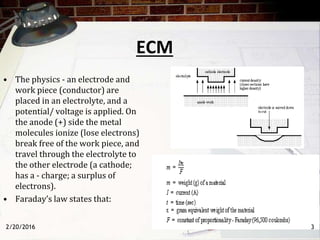

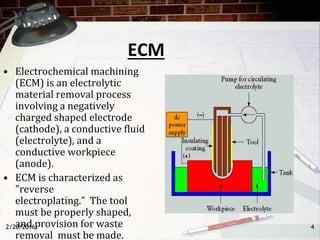

Electrochemical machining (ECM) is an unconventional machining process based on electrolysis that efficiently removes material from conductive workpieces using a negatively charged tool and an electrolyte. It enables the machining of hard materials without thermal or mechanical stress, making it suitable for complex shapes and delicate components, and is increasingly used in industries like automotive and aerospace. ECM compares favorably to other processes like electro-discharge machining (EDM) in terms of metal removal rates and surface finishes, despite its higher capital costs.