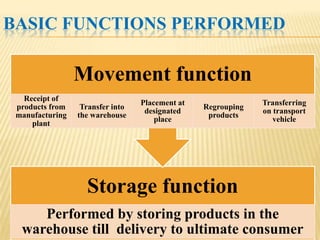

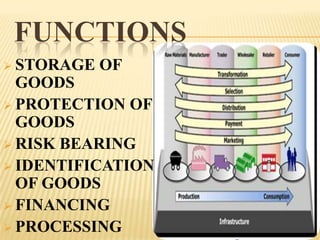

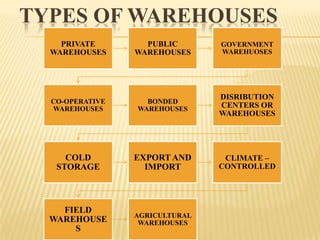

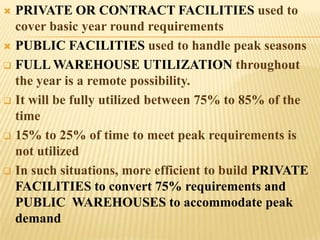

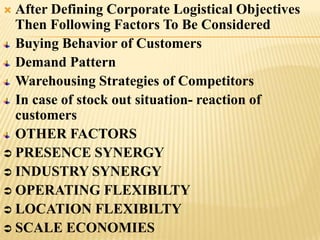

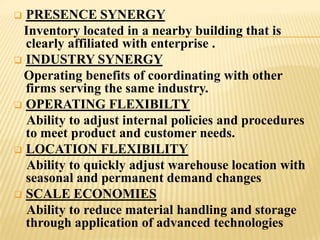

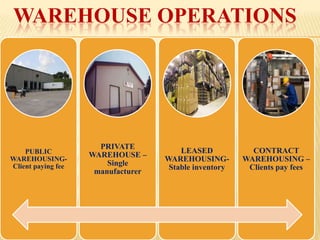

Warehousing refers to the large-scale storage of goods in a systematic manner from the time of production or purchase until use or sale. The key functions of warehousing include storage, preservation, and facilitating the distribution of goods. There are different types of warehouses such as private, public, government, cooperative, and bonded warehouses which vary based on ownership and target users. An effective warehousing strategy considers factors like demand patterns, customer service levels, and total distribution costs.