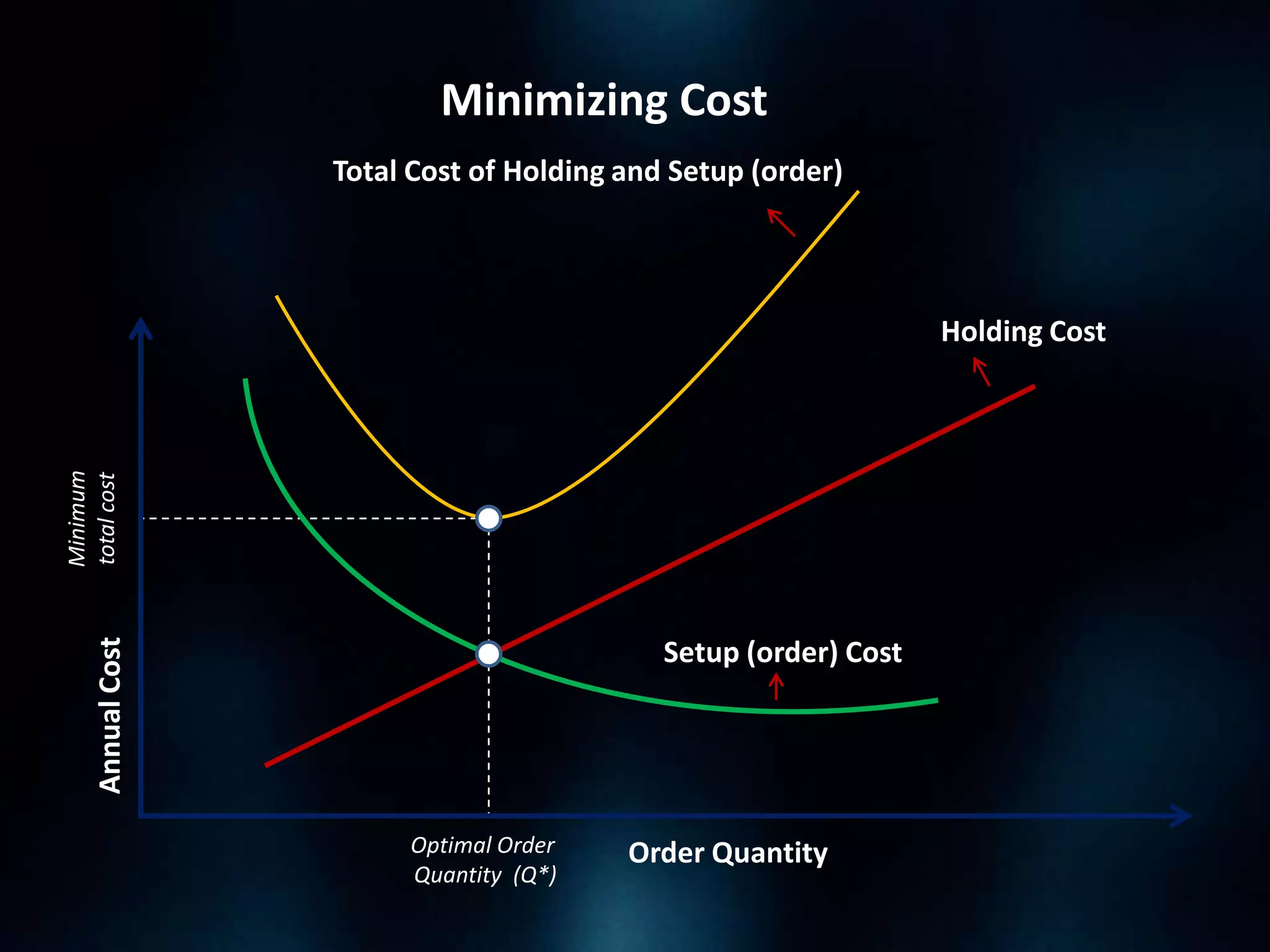

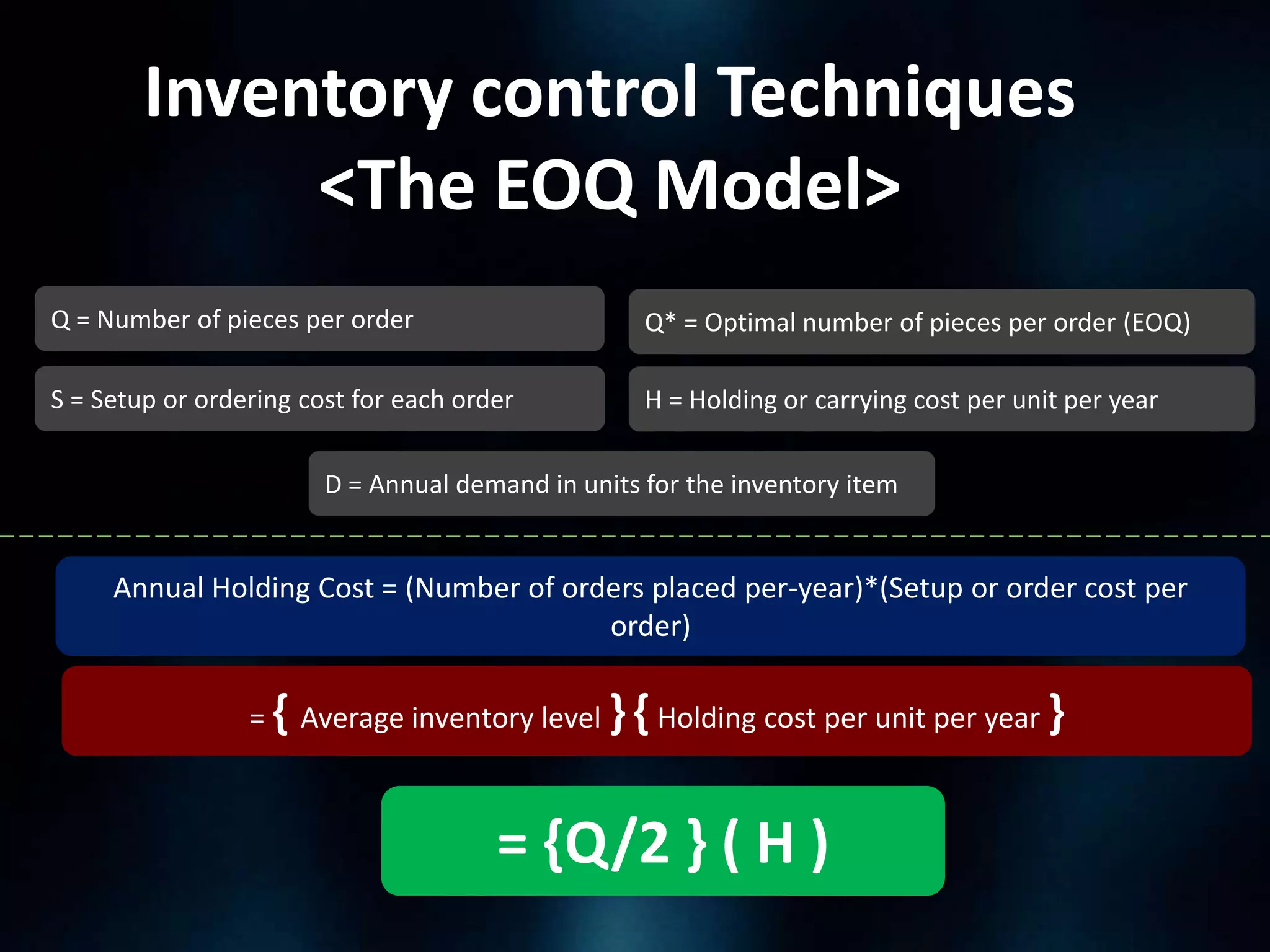

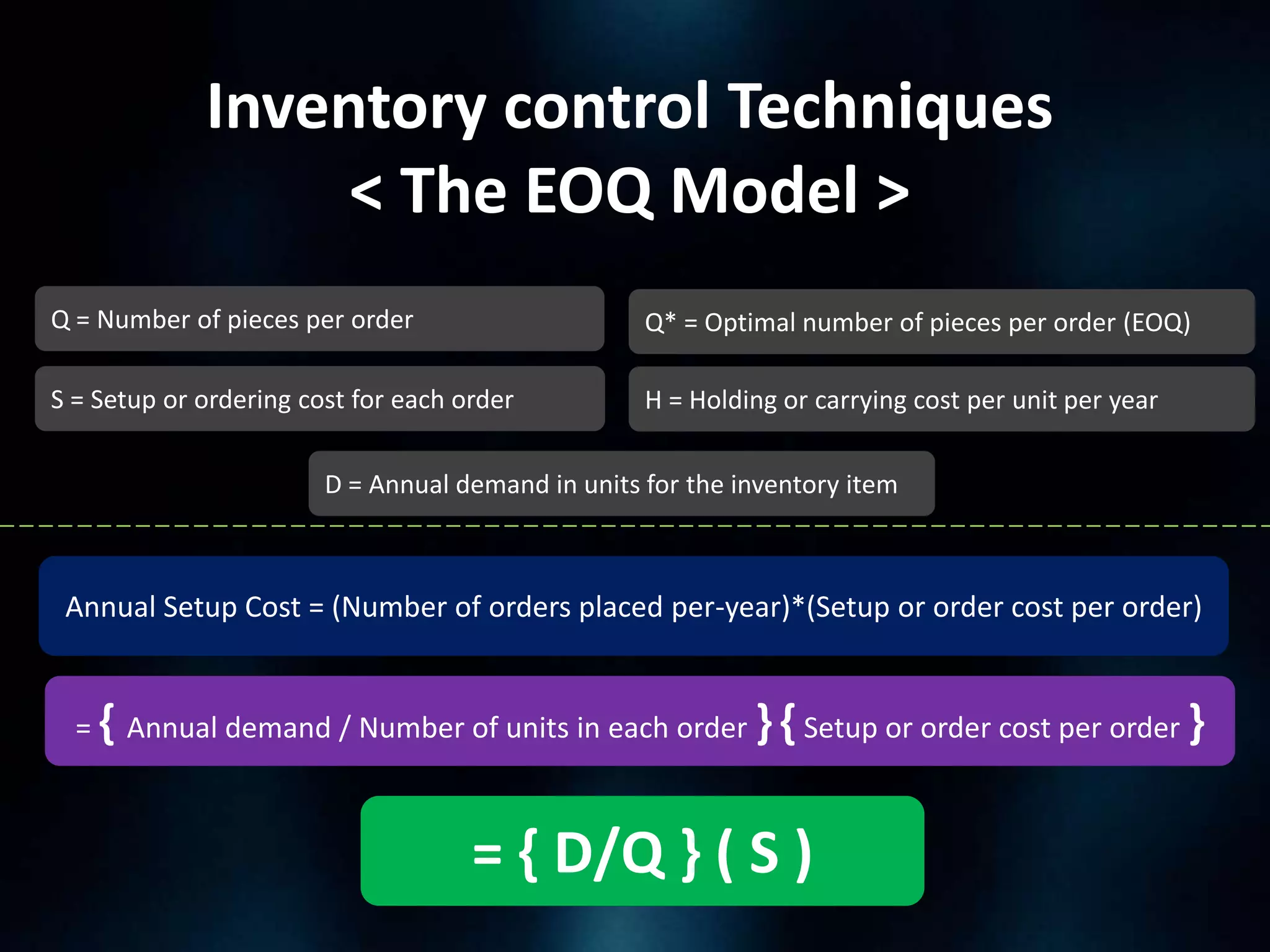

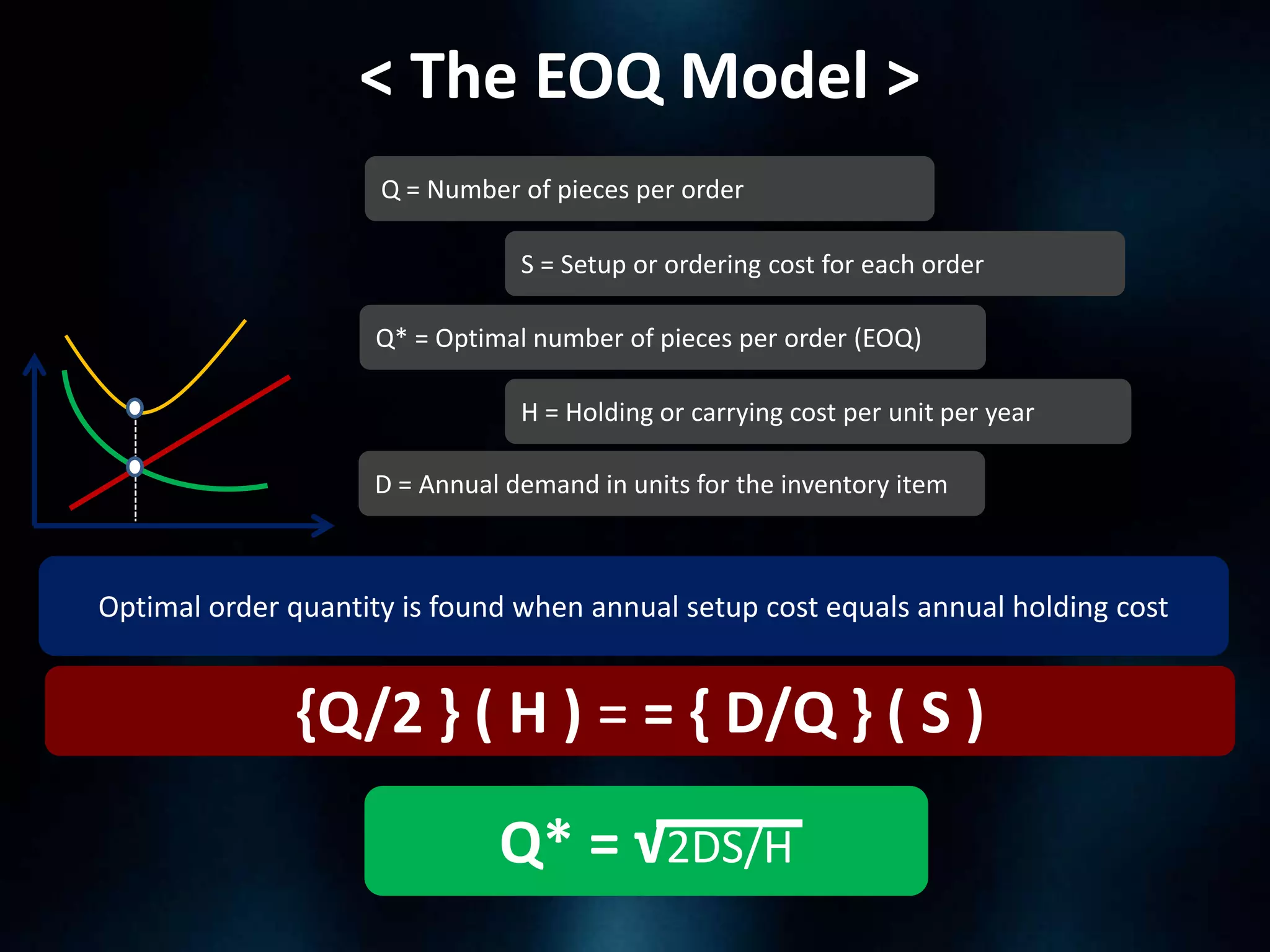

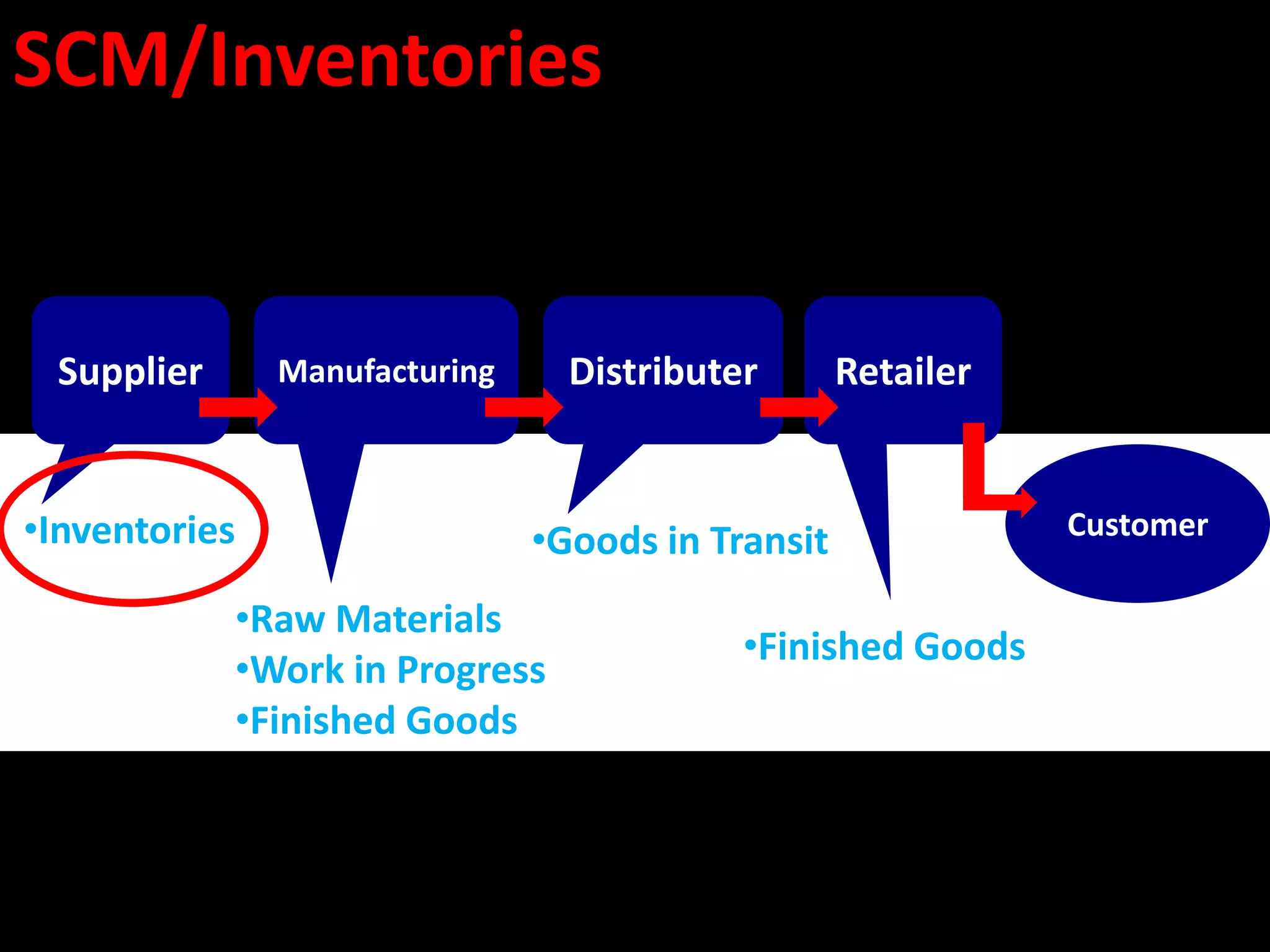

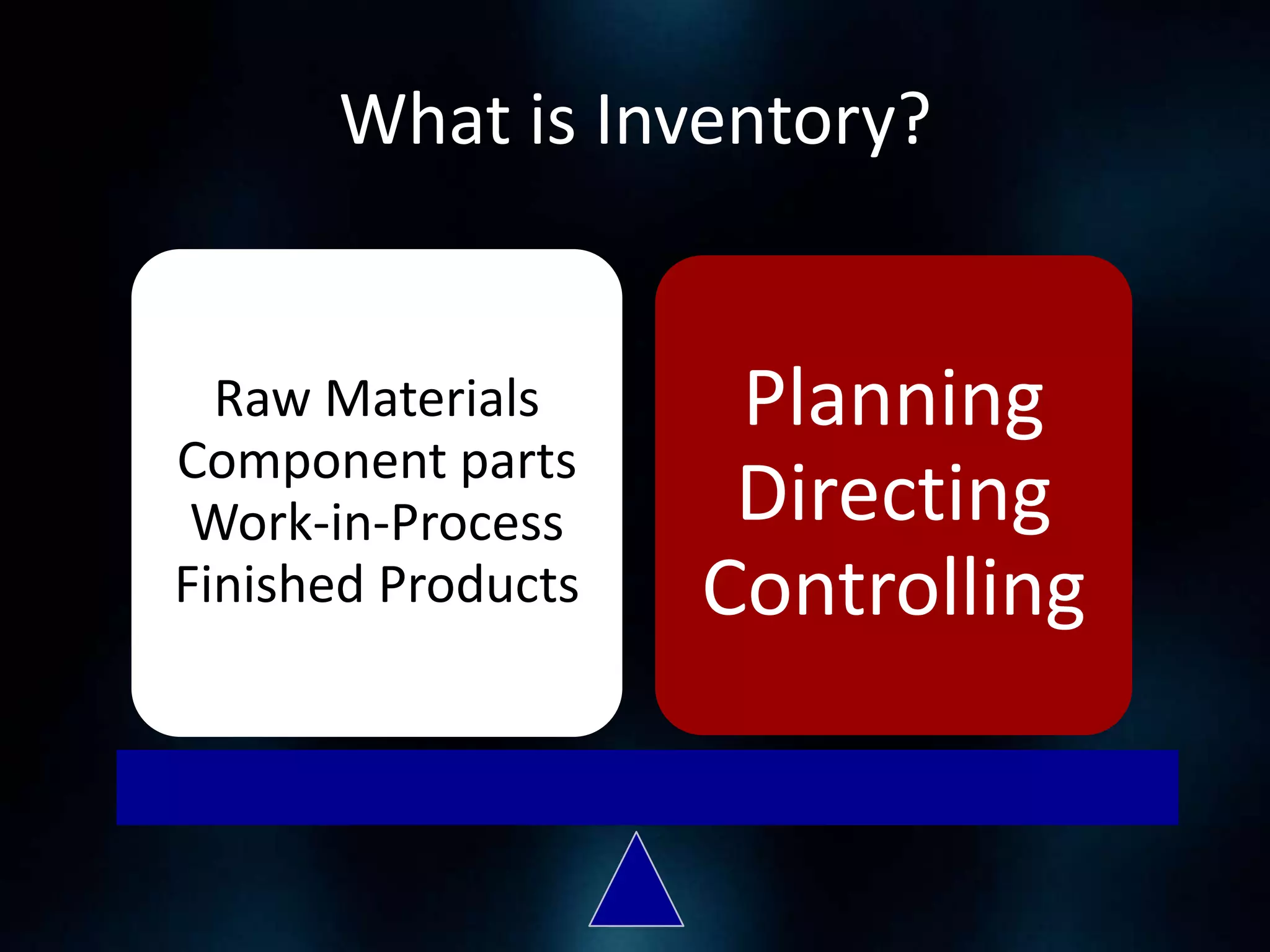

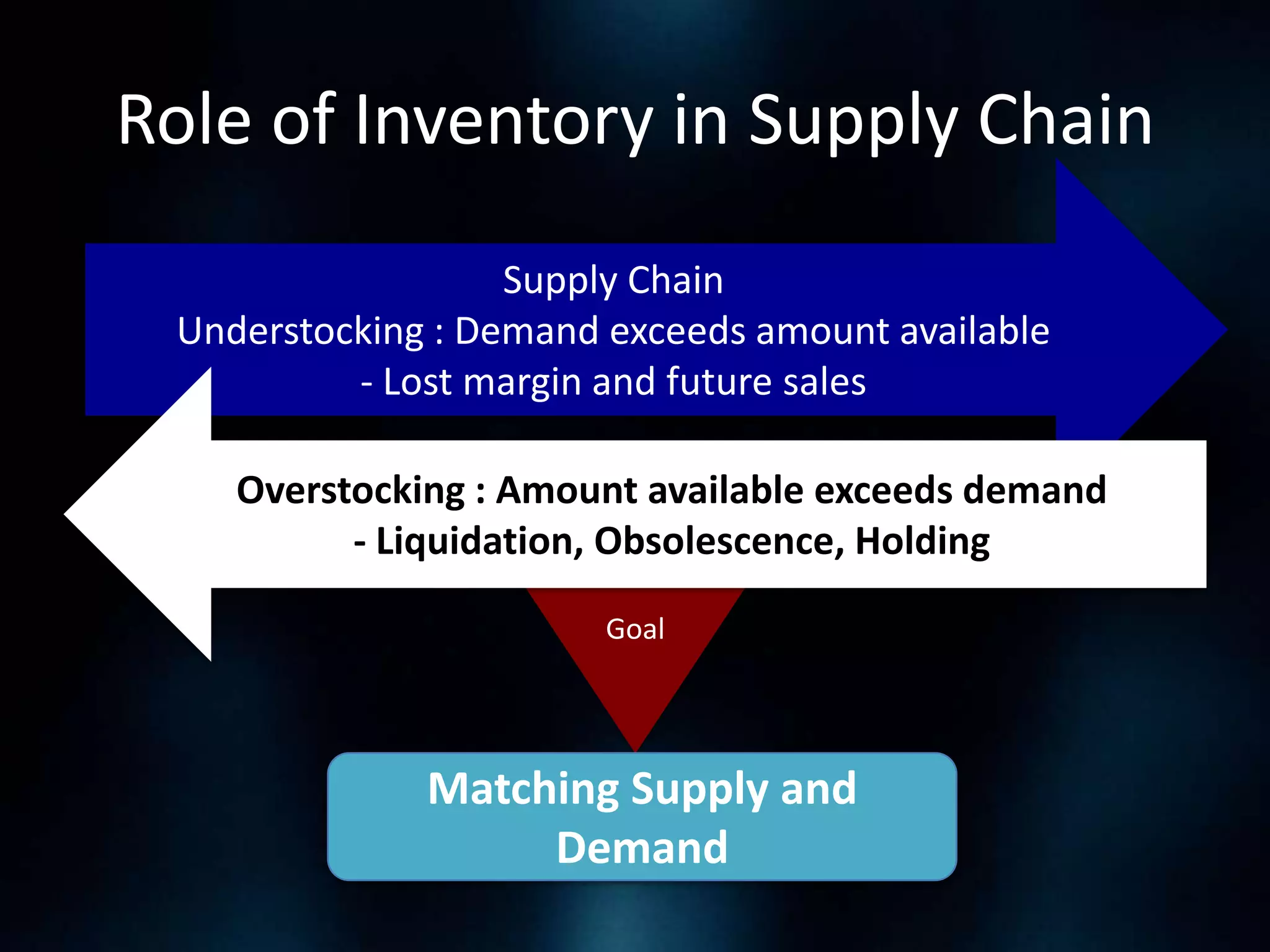

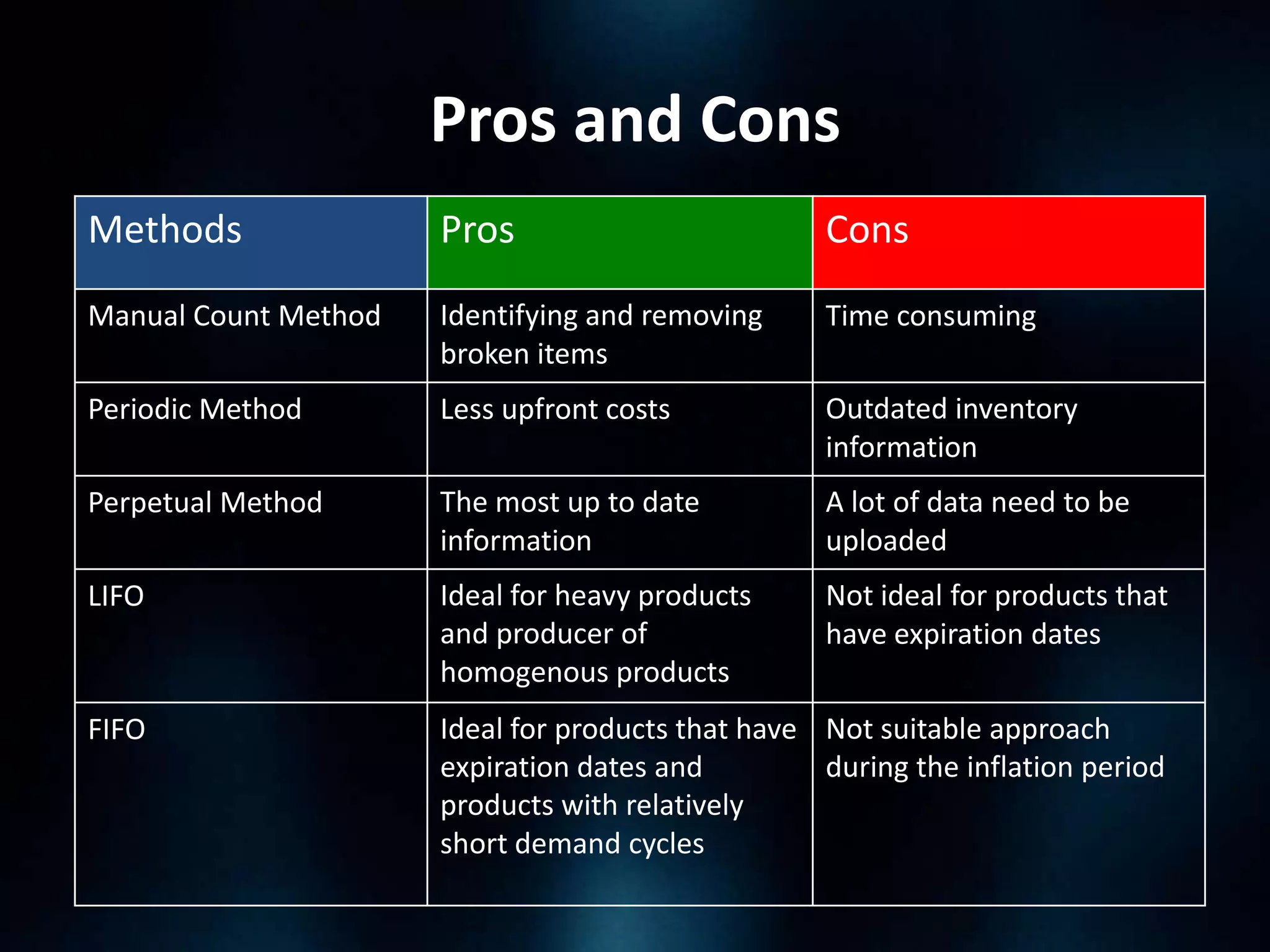

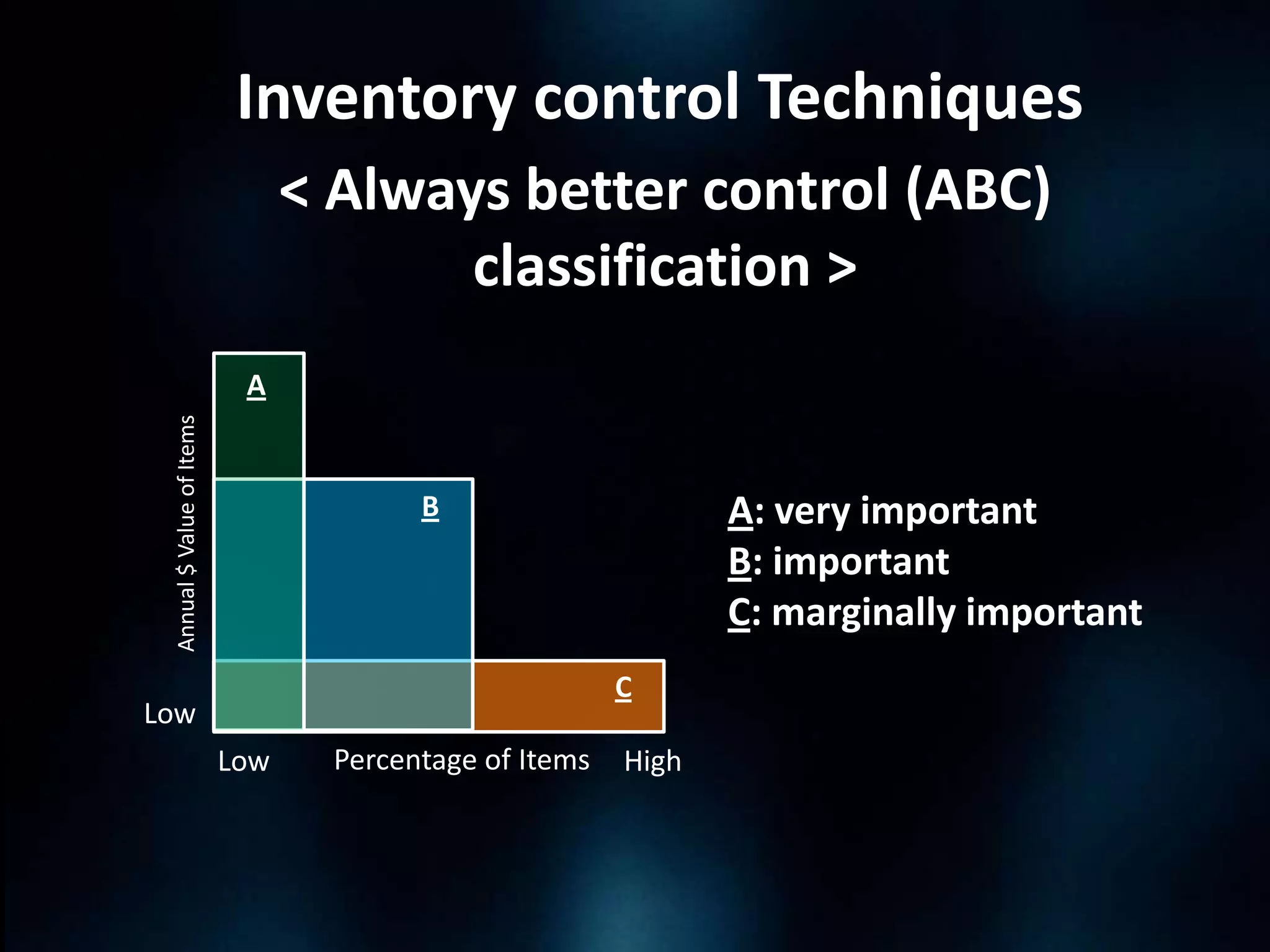

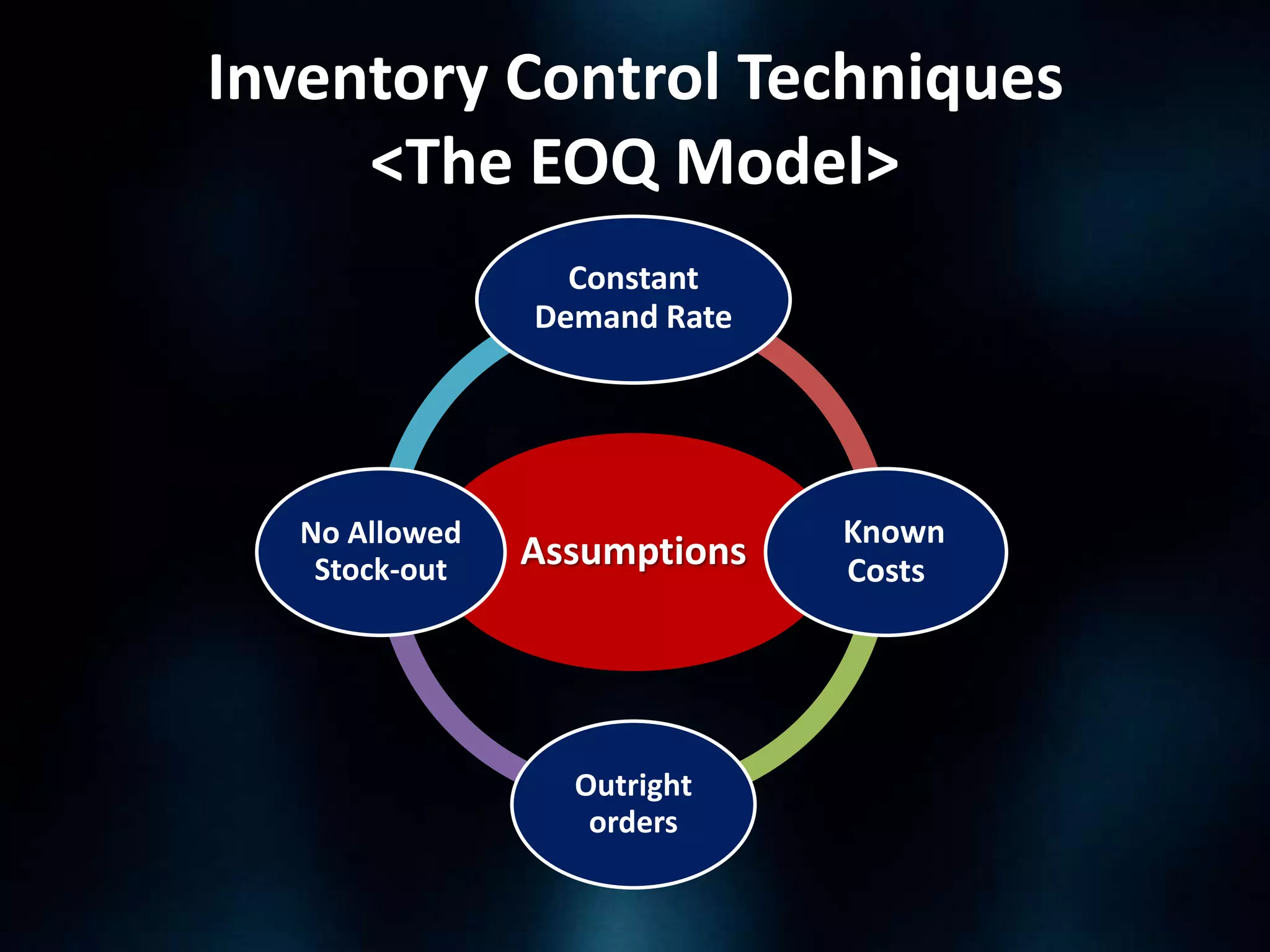

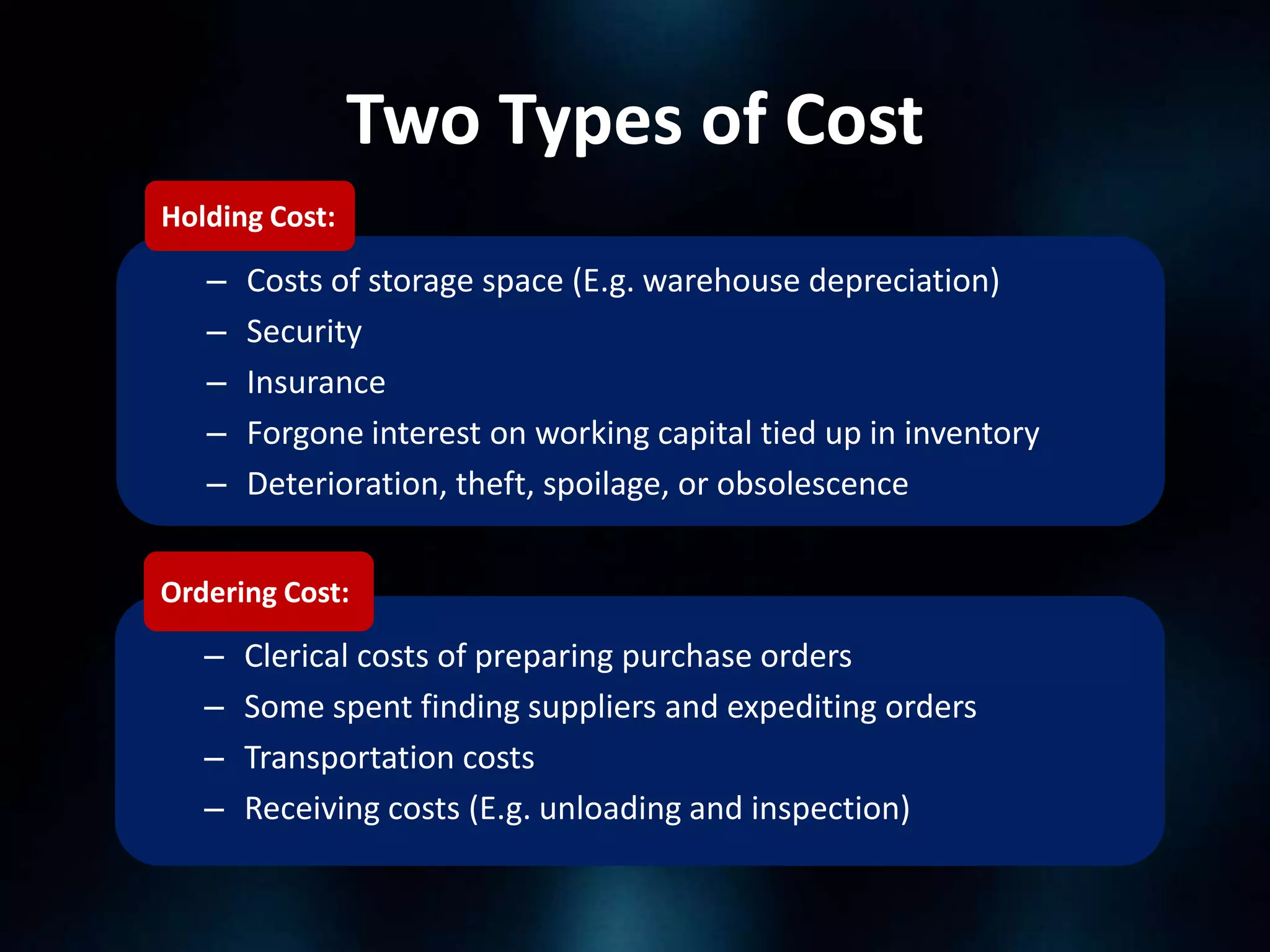

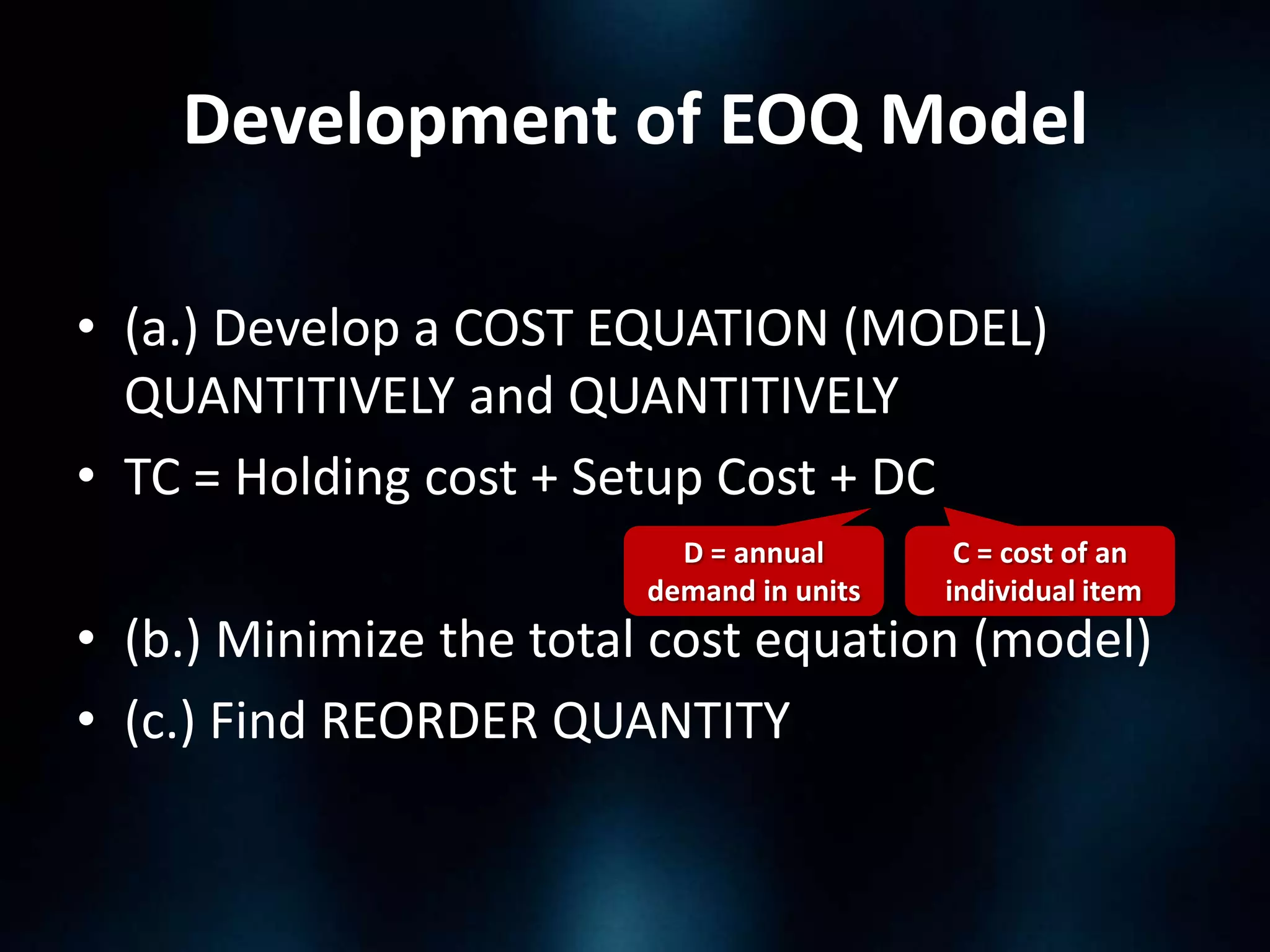

This document discusses inventory management. It defines inventory as raw materials, work in progress, and finished goods. It outlines common myths in inventory management. Inventories are kept for reasons like improving customer service and hedging against uncertainties. The roles of inventory in the supply chain are described. Different types of demands and inventory management techniques like ABC analysis and the economic order quantity model are covered. The benefits and drawbacks of holding inventory are summarized. Different inventory counting and valuation methods are also discussed.

![Inventory Usage Over Time

Order Quantity

Usage

Rate

[maximum inventory level]

Q

Inventory Control

Average inventory

on hand

Q/2

0

Minimum

Inventory

Lead time

Time](https://image.slidesharecdn.com/escm-140220230056-phpapp02/75/Inventory-management-in-supply-chain-18-2048.jpg)