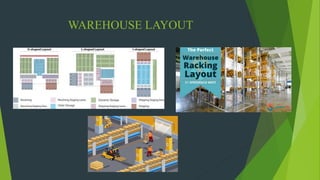

The document discusses warehousing. It defines a warehouse as a storage structure constructed for protecting stored goods' quality and quantity. Warehouses are used by manufacturers, importers, exporters and others to store goods. They create time utility by bridging the time between production and consumption. Warehouses are important as they provide economic benefits through consolidation, act as assembly points, facilitate reverse logistics, enable storage and add value through inventory management. Location, functions, types and layout of warehouses are also covered.