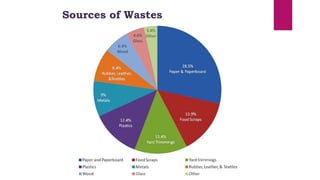

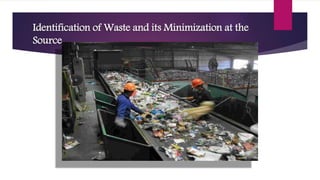

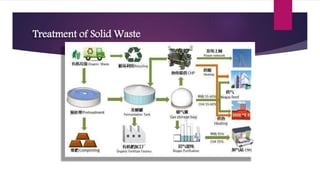

The document discusses solid waste management. It defines solid waste and describes the different types - municipal, industrial, and hazardous waste. It explains the sources of waste like households, industries, agriculture, and fisheries. It then covers the components of solid waste management like waste identification and minimization, collection, transportation, treatment, and energy recovery. Treatment methods for solid waste are also outlined like composting, vermicomposting, anaerobic digestion. The importance of community involvement in cleanliness initiatives like Swachh Bharat Abhiyan is highlighted.