- Warehouses are buildings used for storage of goods and are usually located in industrial areas. They are used by manufacturers, importers, exporters, and wholesalers.

- The primary objectives of warehouses are to facilitate the movement of goods, provide timely customer service, keep accurate records of inventory, minimize costs associated with moving goods, and provide communication with customers.

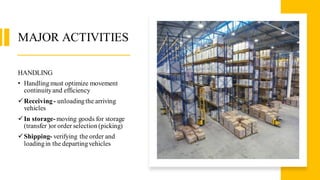

- Warehouses perform various functions including receiving, identifying, sorting, storing, retrieving, packing, and dispatching goods as well as maintaining accurate records.