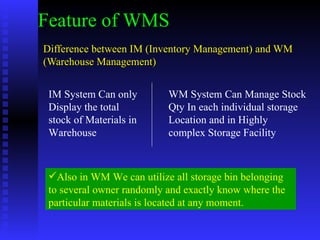

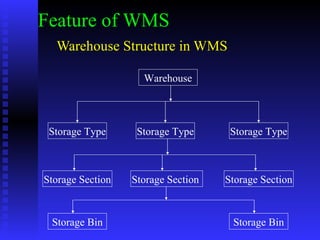

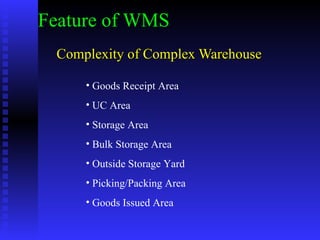

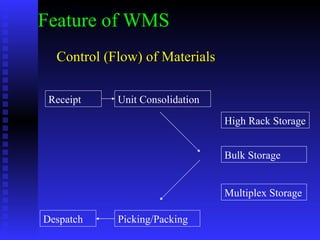

WMS supports key warehouse processes like managing complex warehouse structures, optimizing material flows through advanced binning and picking techniques, and quickly processing goods receipt, issue, and transfers. It provides benefits like optimization of capacity and material flows, monitoring of stock levels in storage areas and bins, and knowing the actual occupied and empty space percentages in the warehouse. Key features include creating multiple warehouse locations, locating materials randomly within them, handling different storage types, and controlling material receipt, consolidation, storage, picking, packing and dispatch flows.