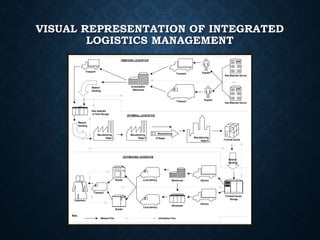

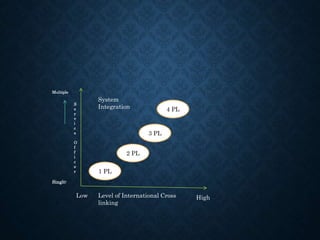

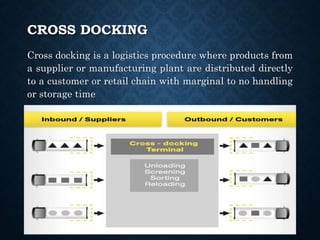

The document discusses logistics and supply chain management. It defines logistics as planning, implementing, and controlling the efficient flow of goods, services, and information from origin to consumption according to customer needs. Logistics involves functions like procurement, inventory control, warehousing, transportation, and customer service. It also discusses types of logistics like inbound, outbound, third-party, and reverse logistics. The document then summarizes a case study of Ford Motor Company partnering with Penske to centralize its logistics network, resulting in cost savings and efficiency improvements.