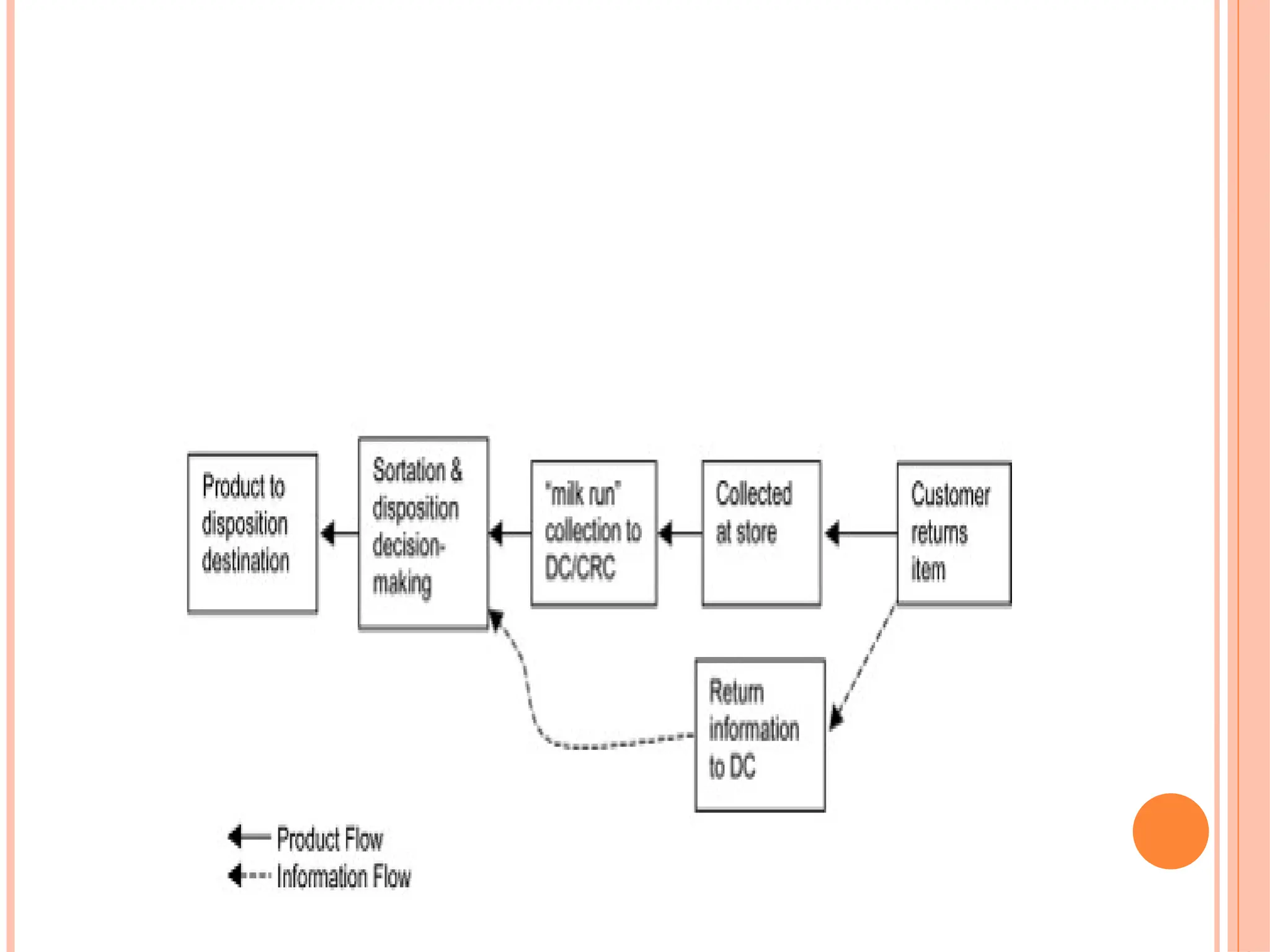

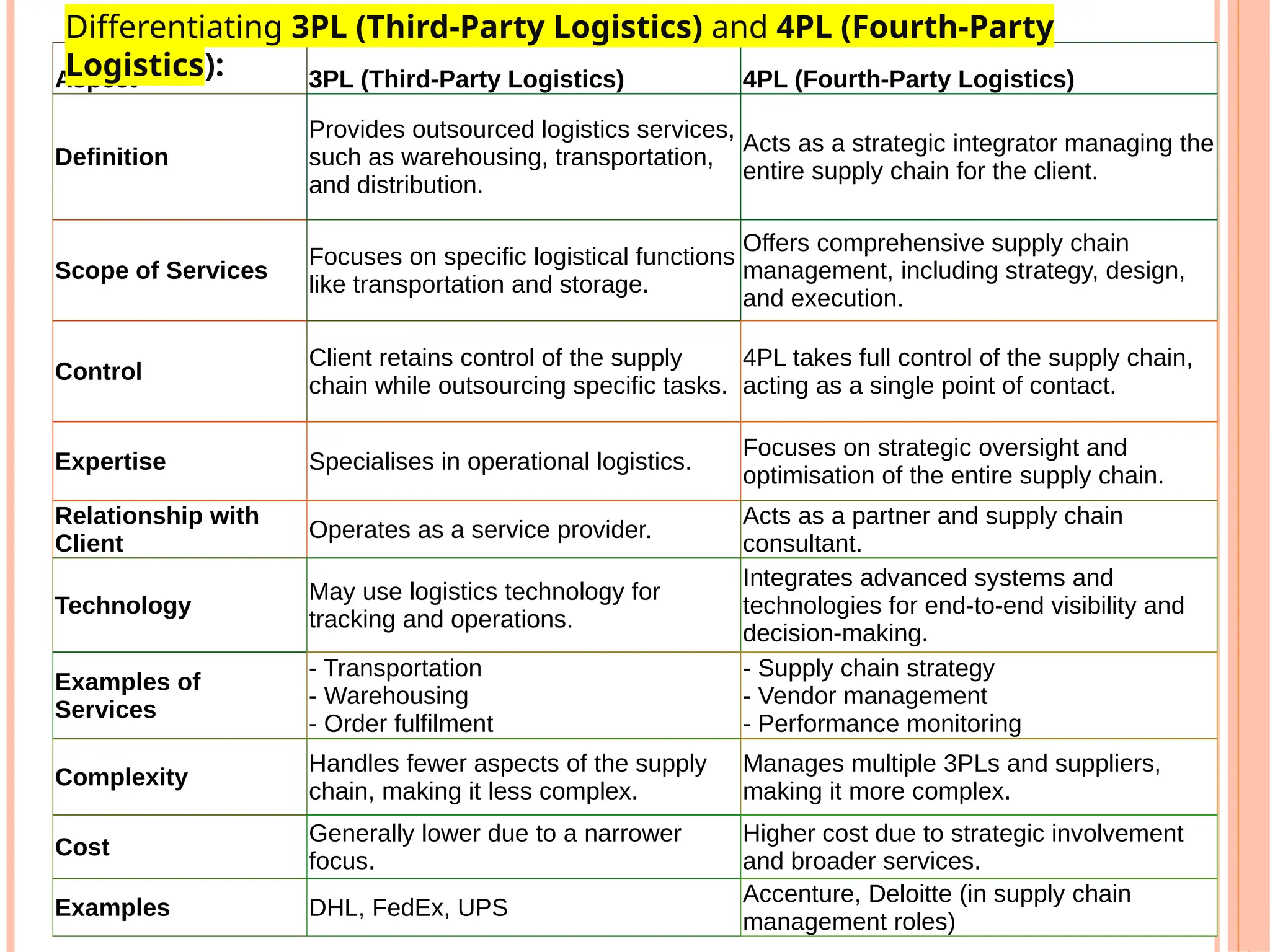

The document outlines the concept, types, and importance of warehousing and its role in logistics, highlighting functions such as storage, price stabilization, risk management, and financing. It explains different warehouse types, including private, public, and bonded warehouses, and emphasizes the significance of logistics network design and reverse logistics for improving efficiency and sustainability in operations. Additionally, it discusses the nature of outsourcing and its benefits in reducing costs and enhancing business focus.