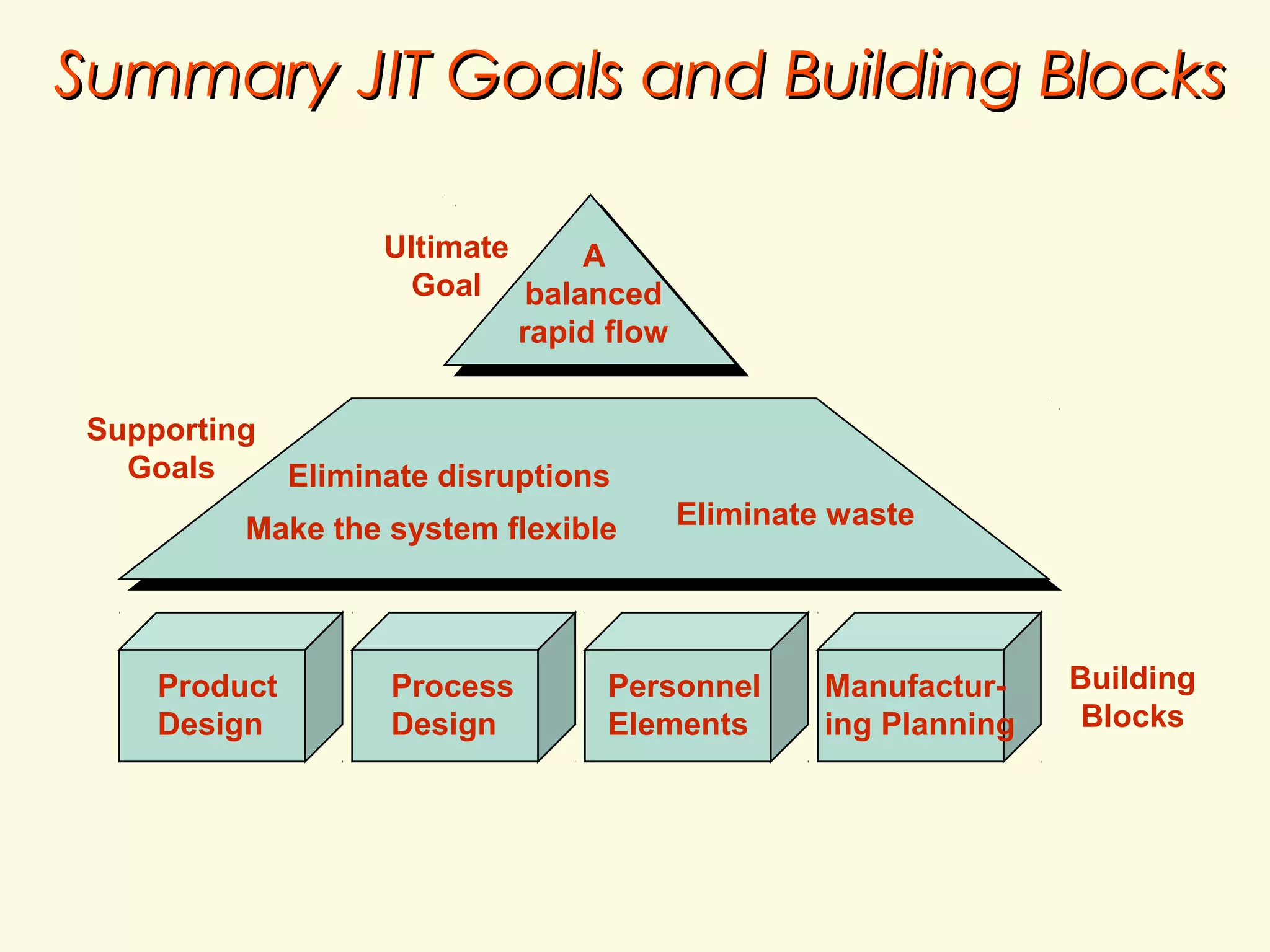

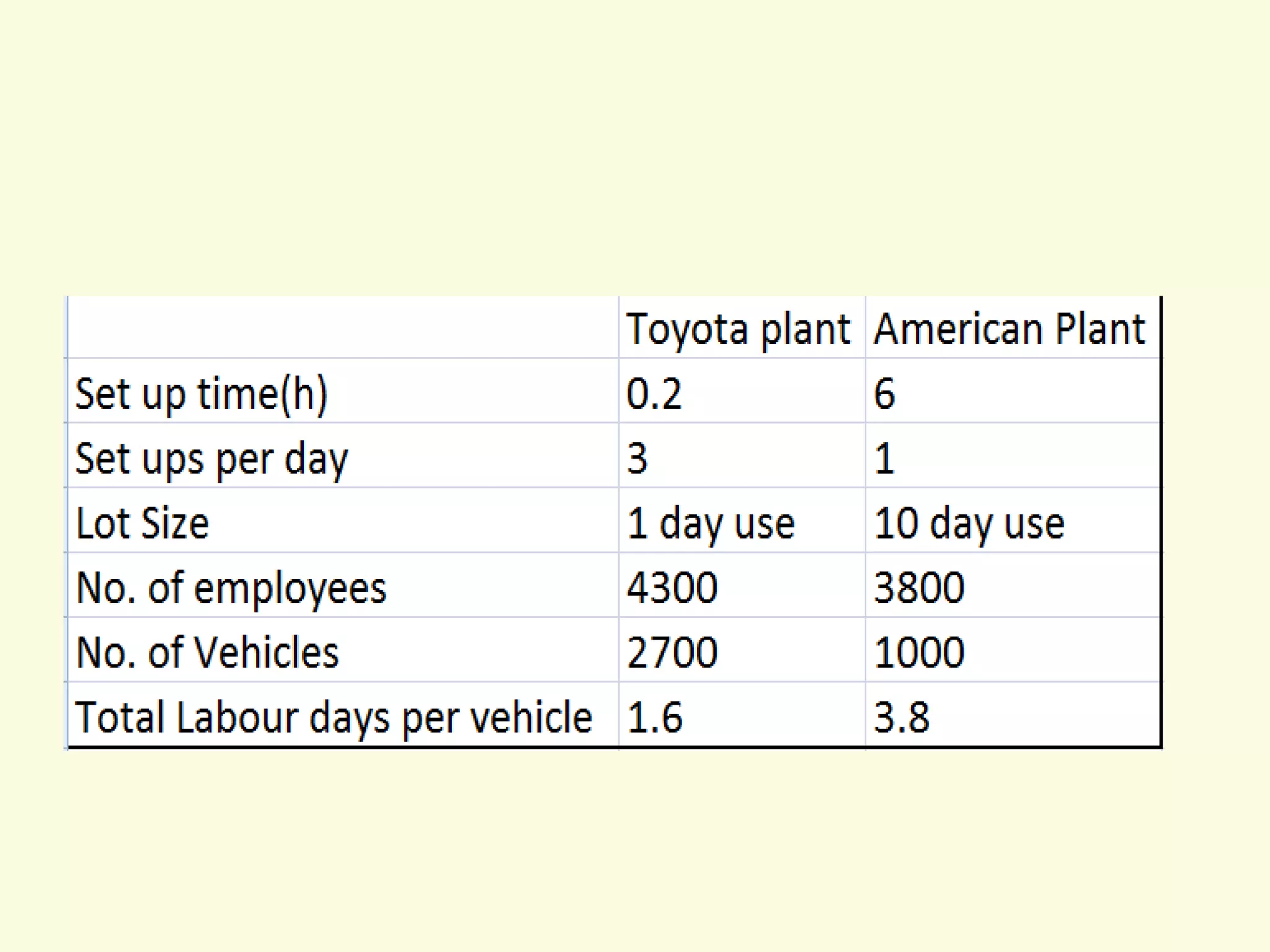

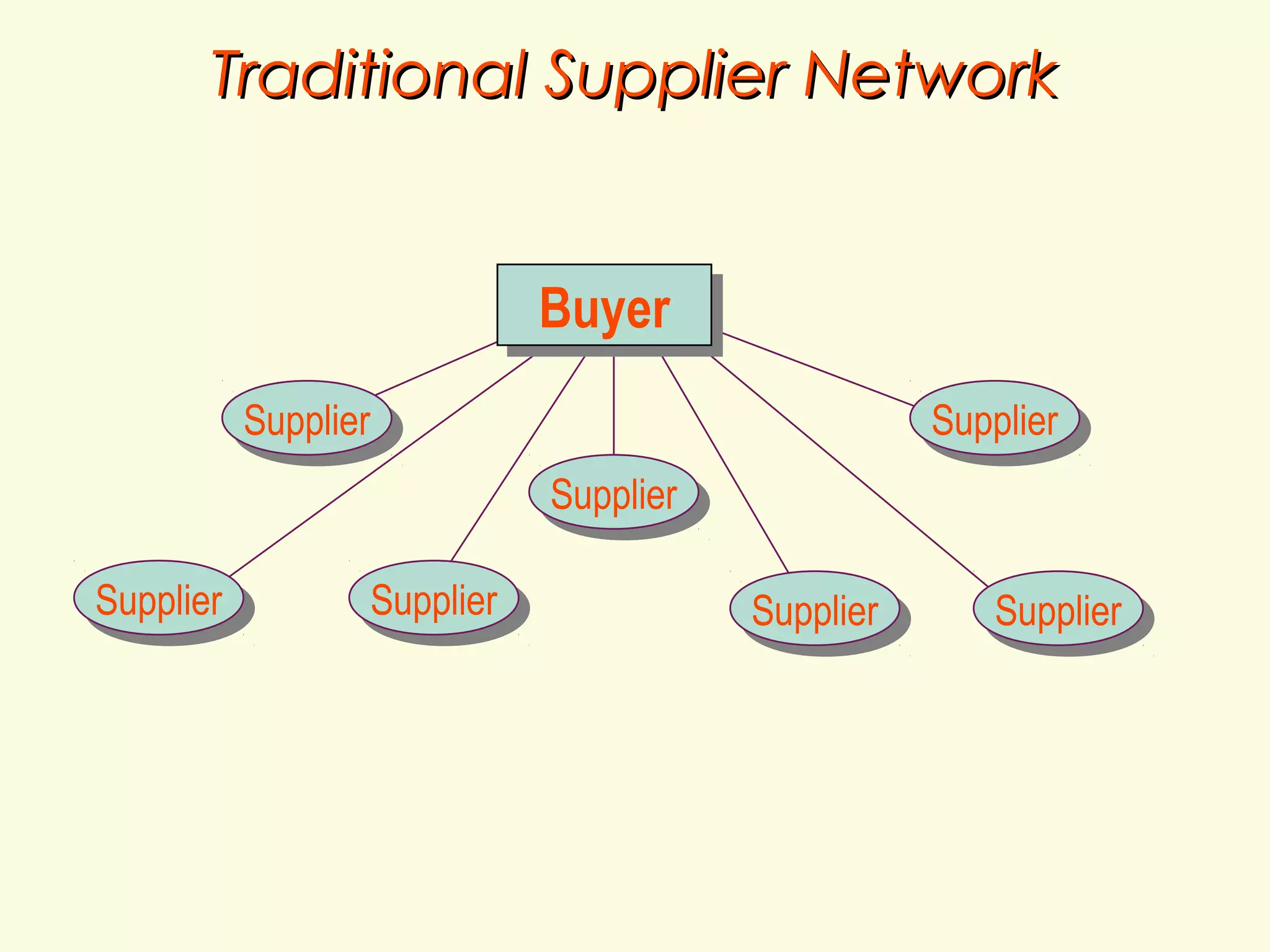

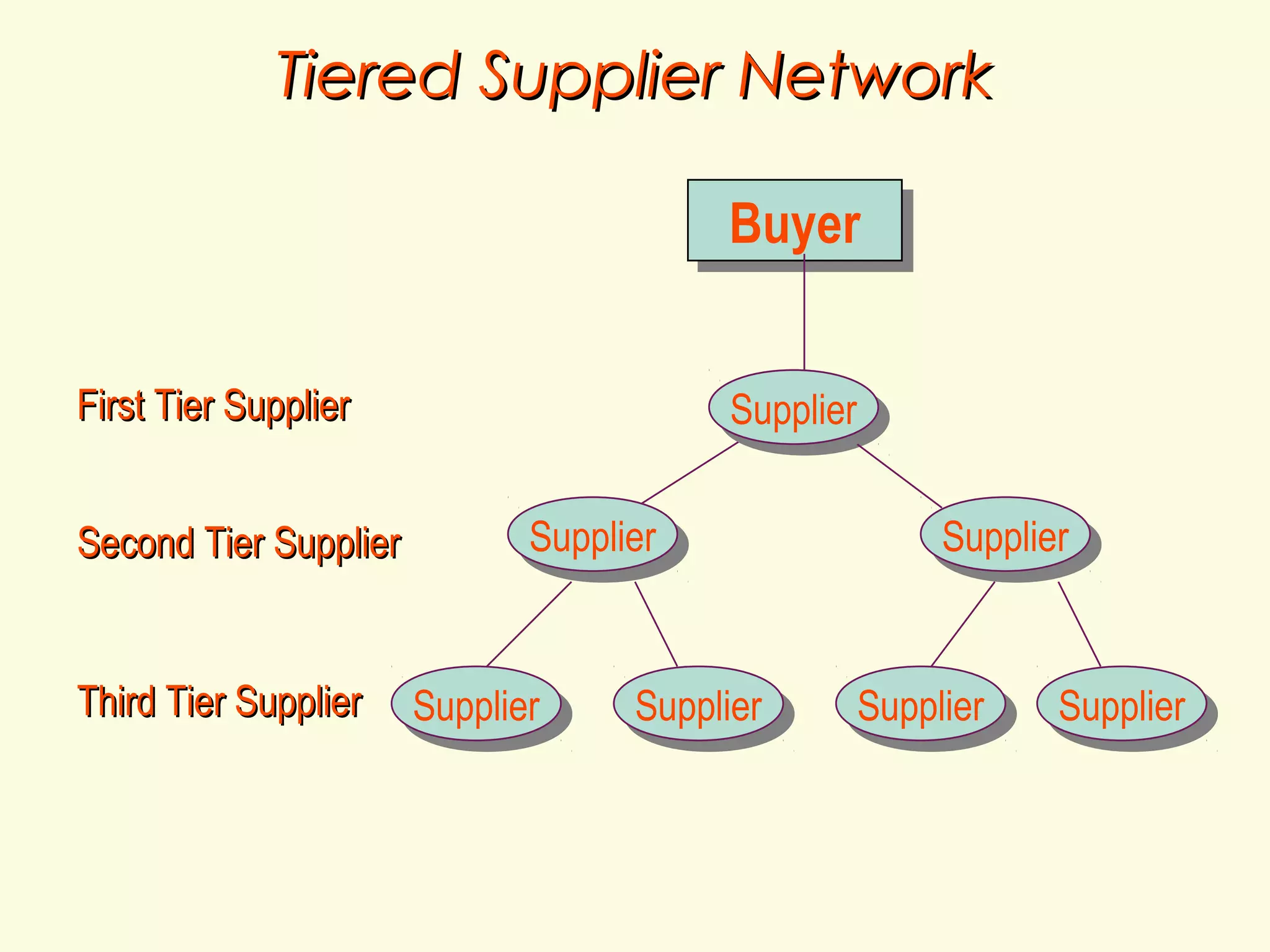

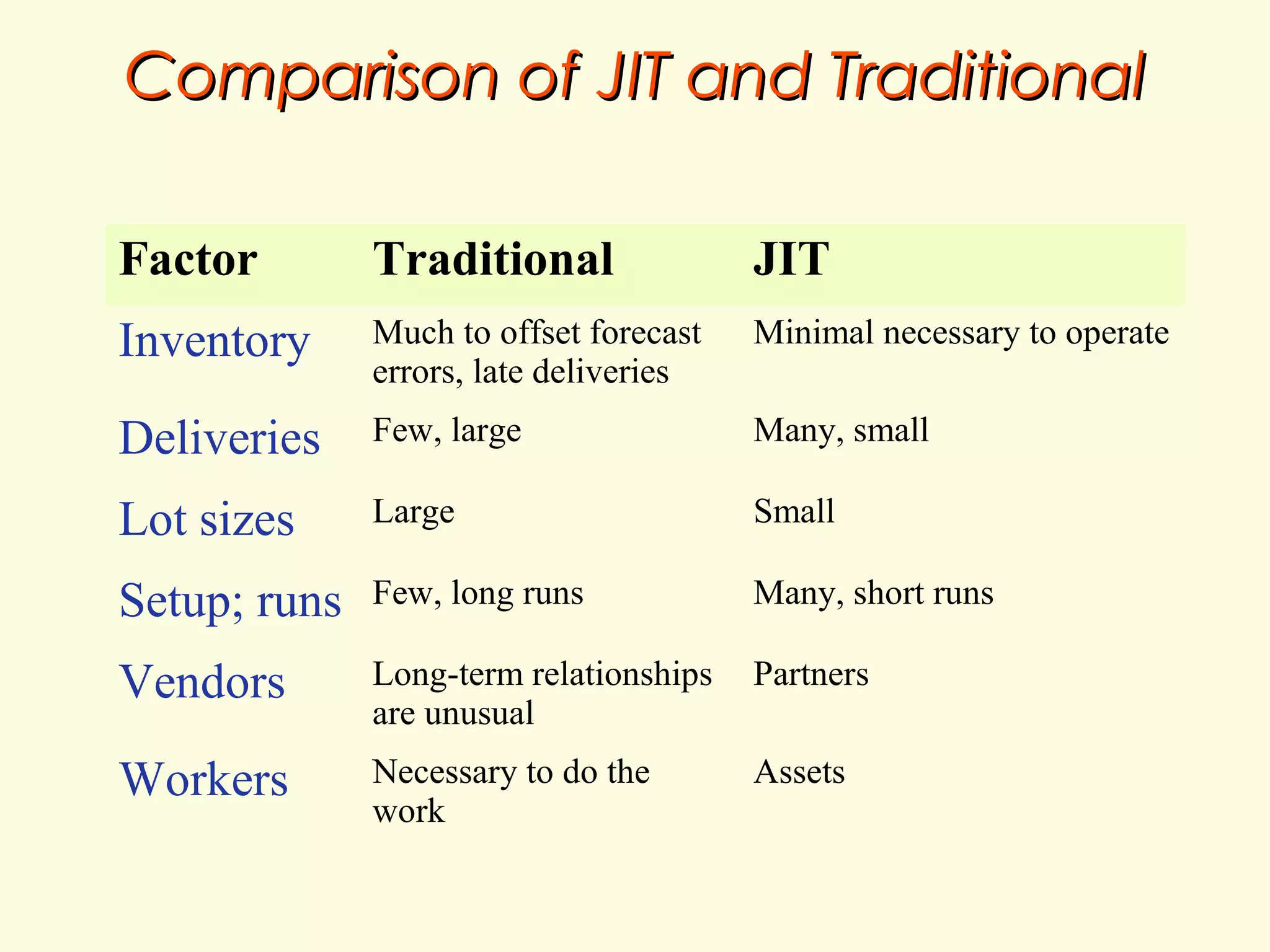

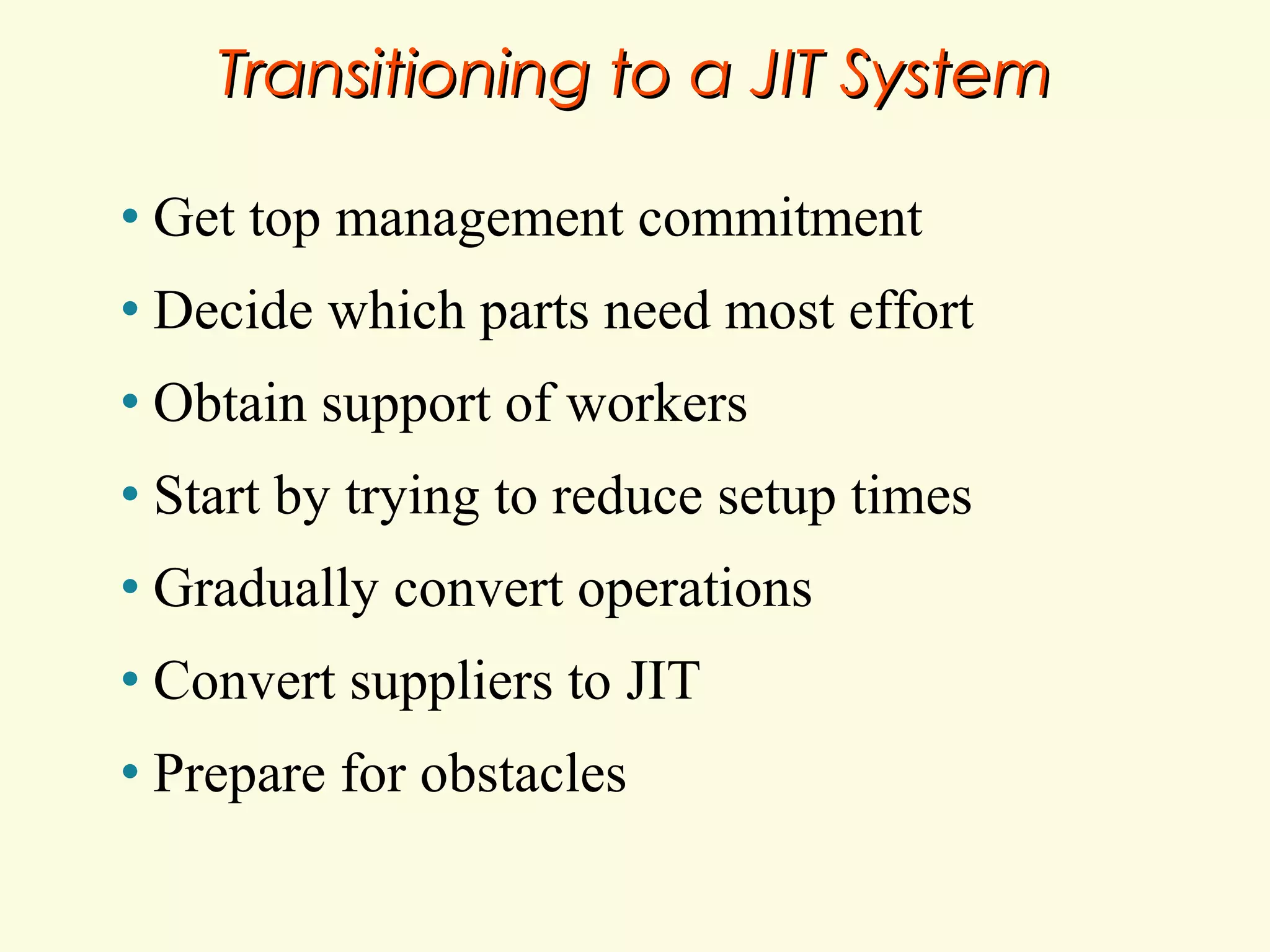

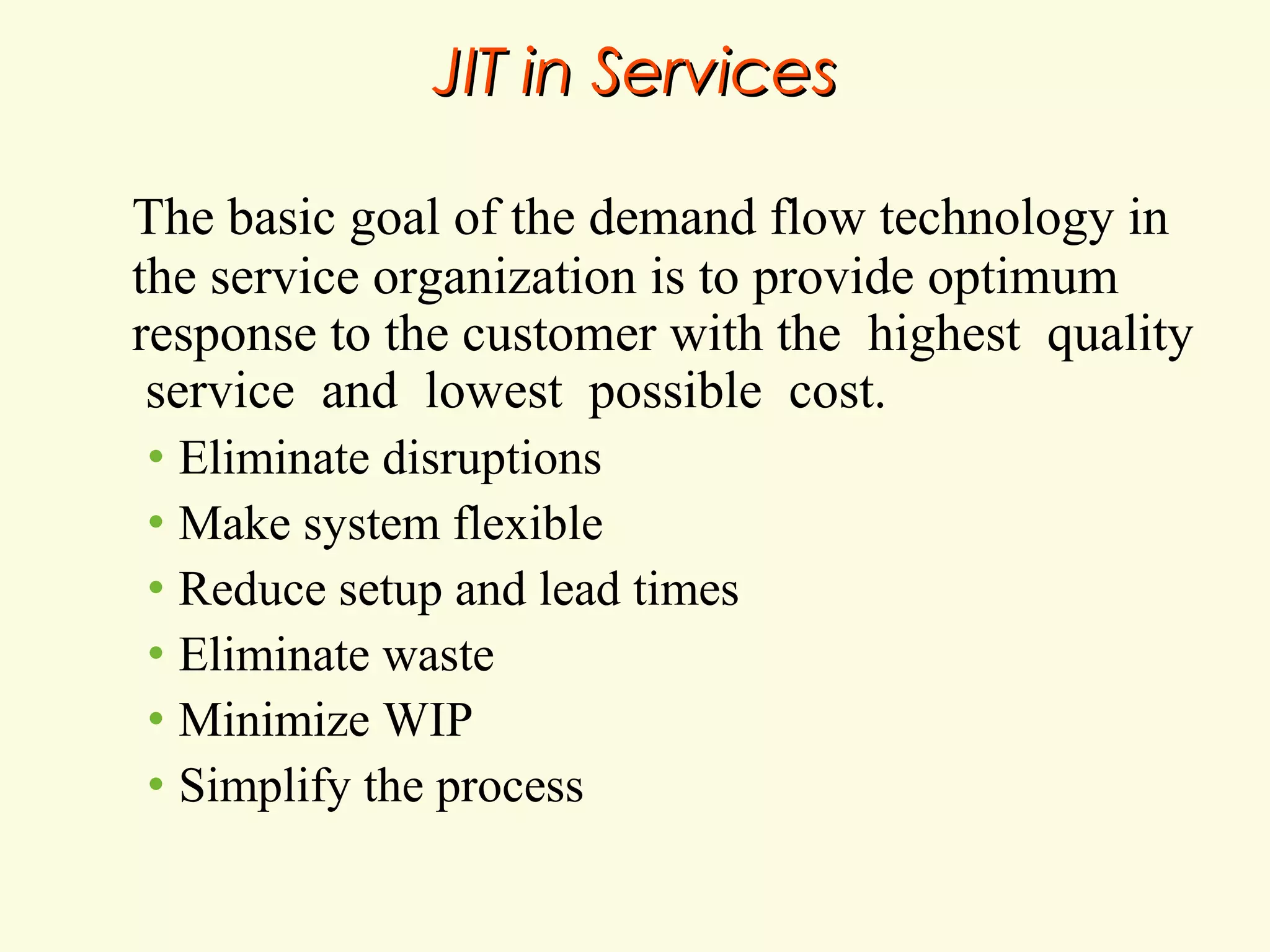

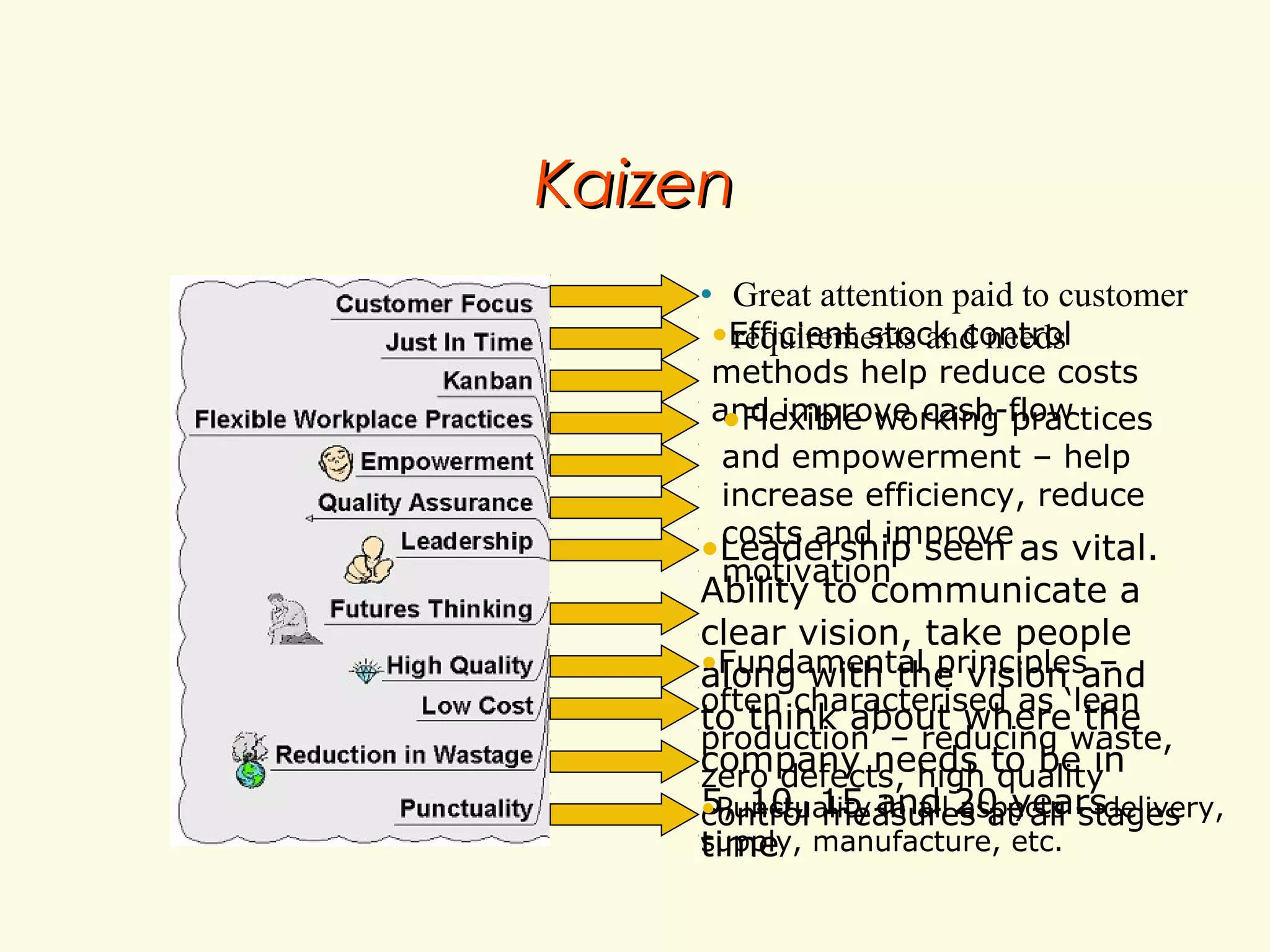

Just-in-time (JIT) production is a highly coordinated manufacturing system that produces goods and services just as they are needed. The ultimate goal of JIT is to achieve a smooth, rapid flow of materials through the production system with minimal inventories, waste, and transactions. Key elements of JIT include small lot sizes, continuous improvement, visual control systems like Kanban, and close supplier relationships. Benefits of JIT include reduced inventory levels, higher quality, flexibility, and increased productivity.