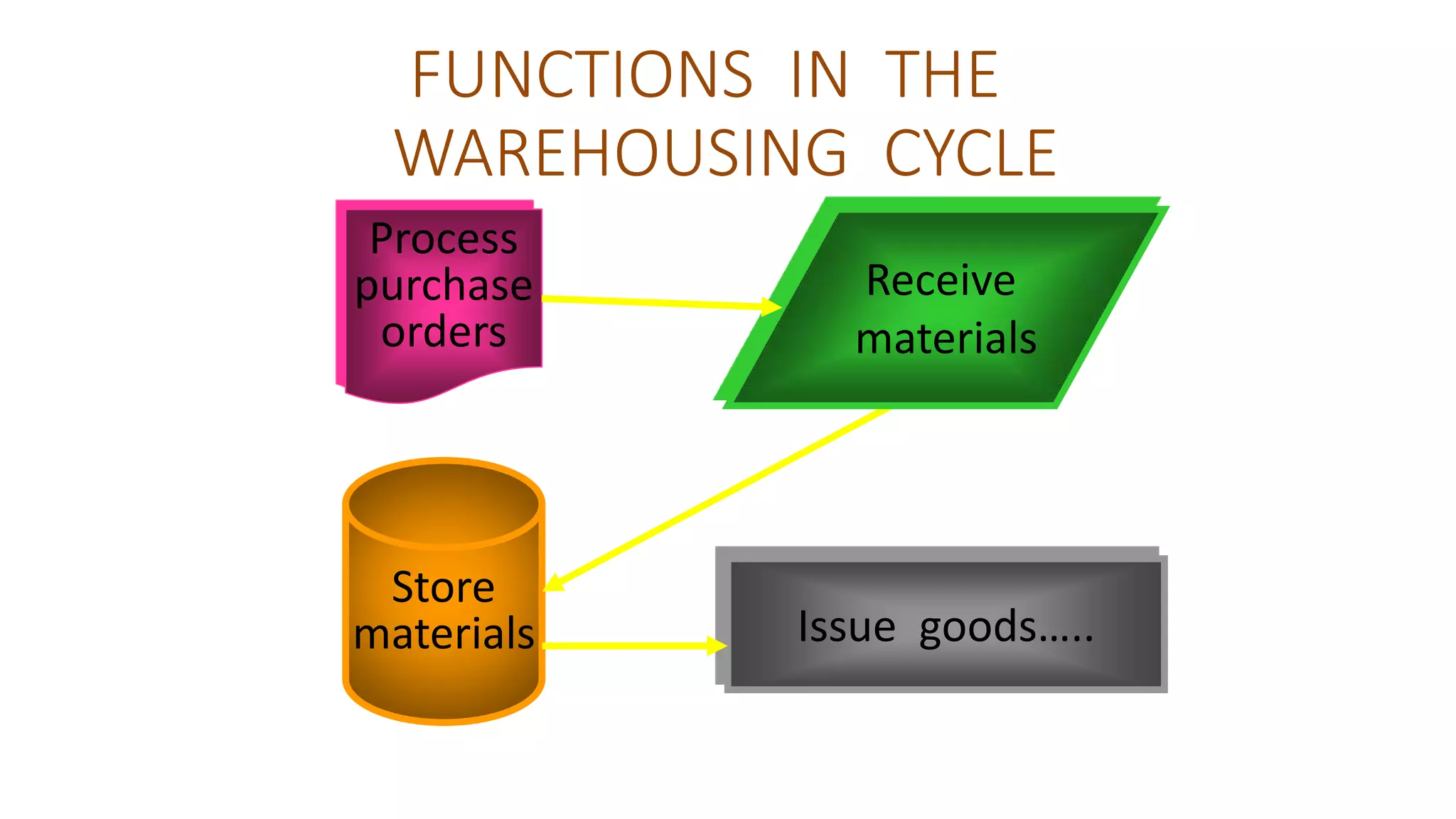

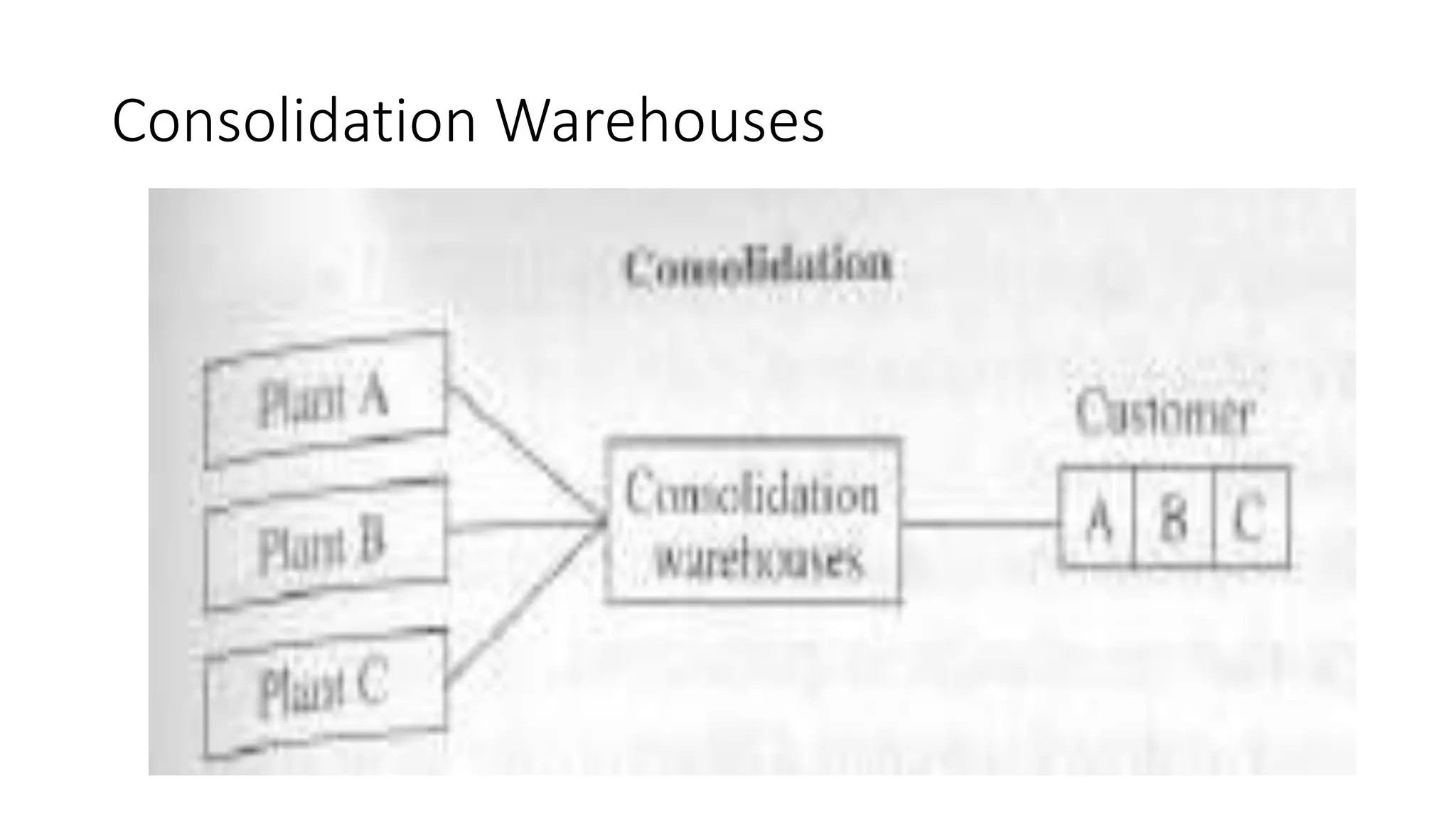

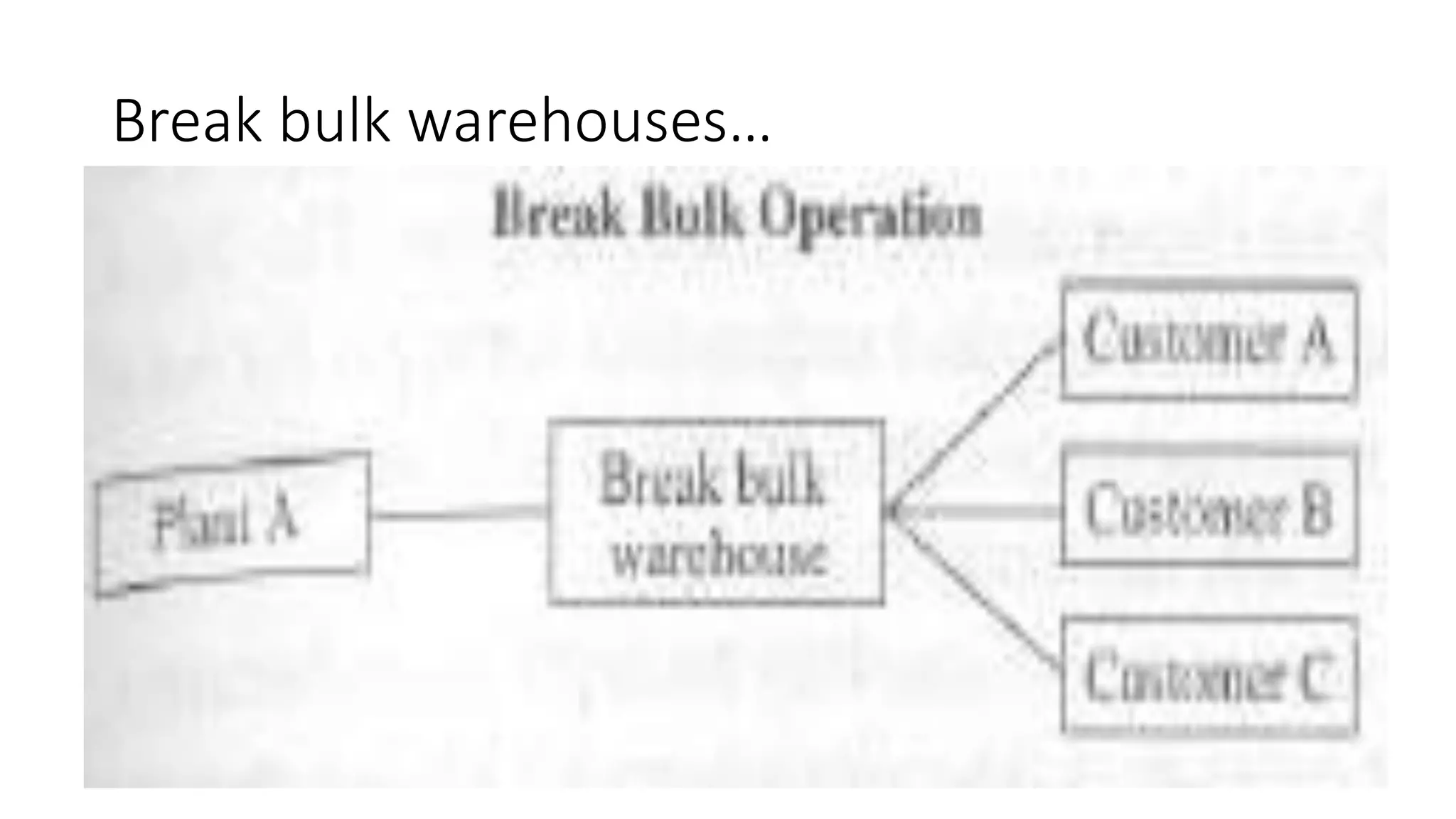

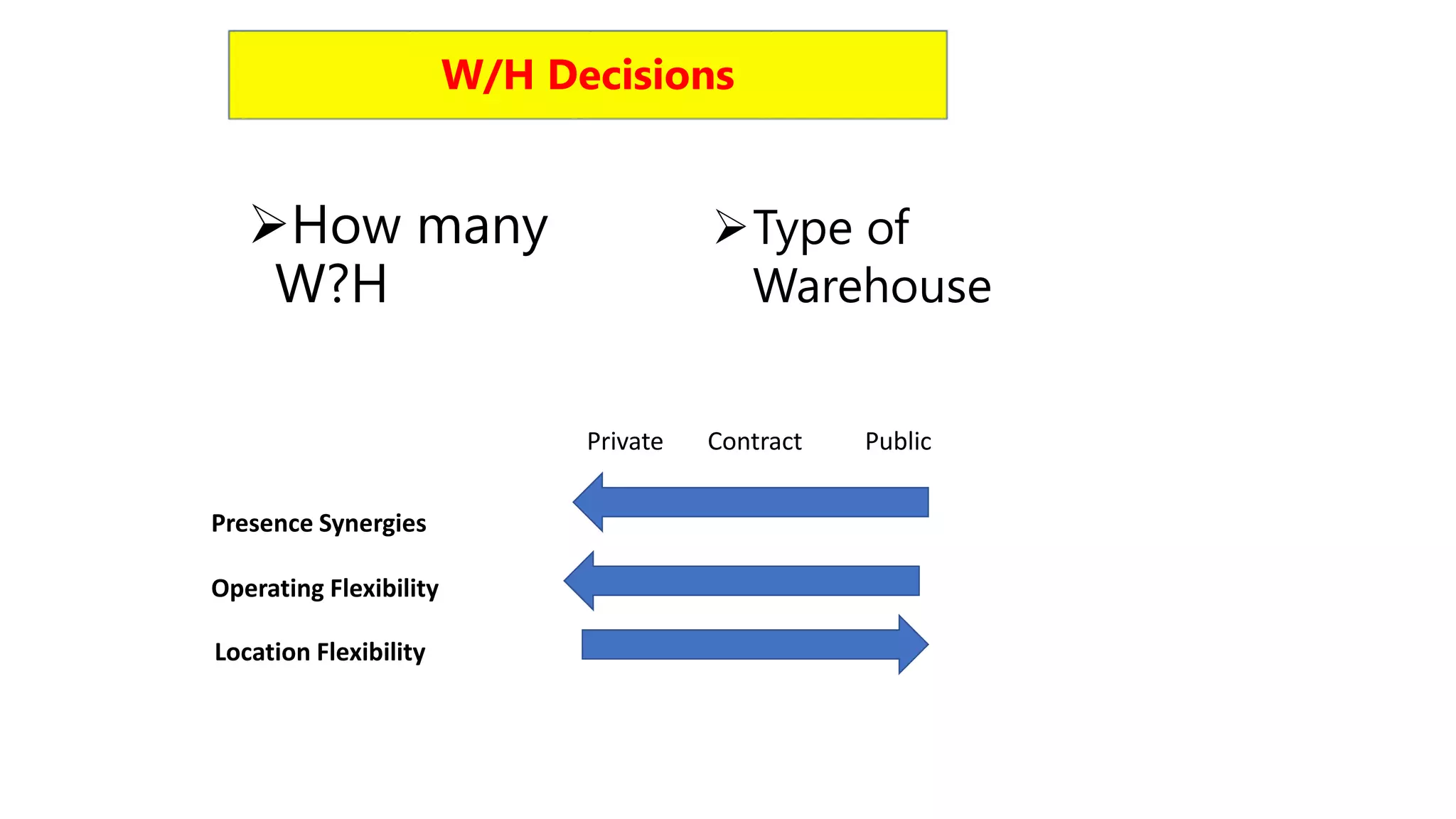

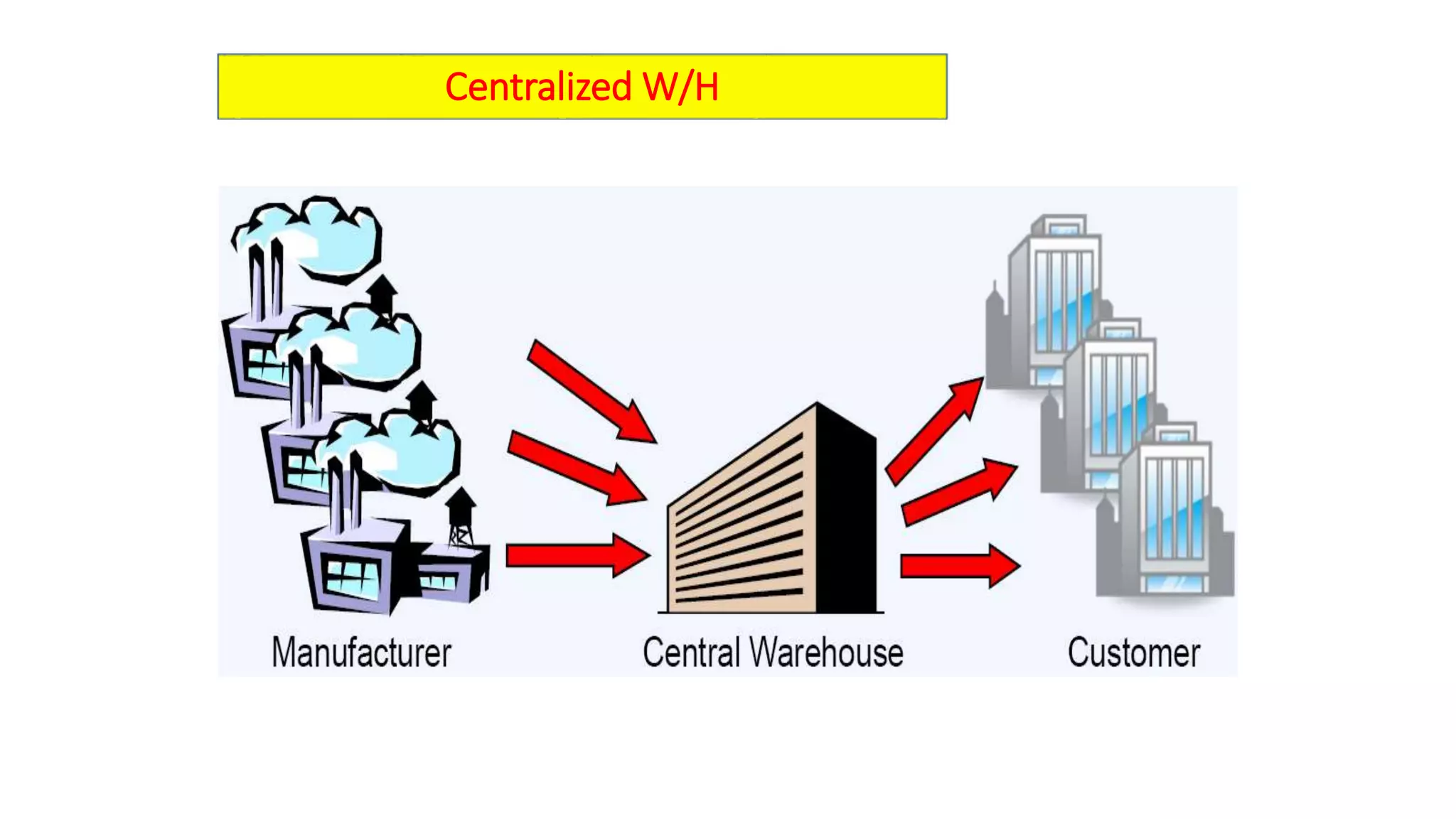

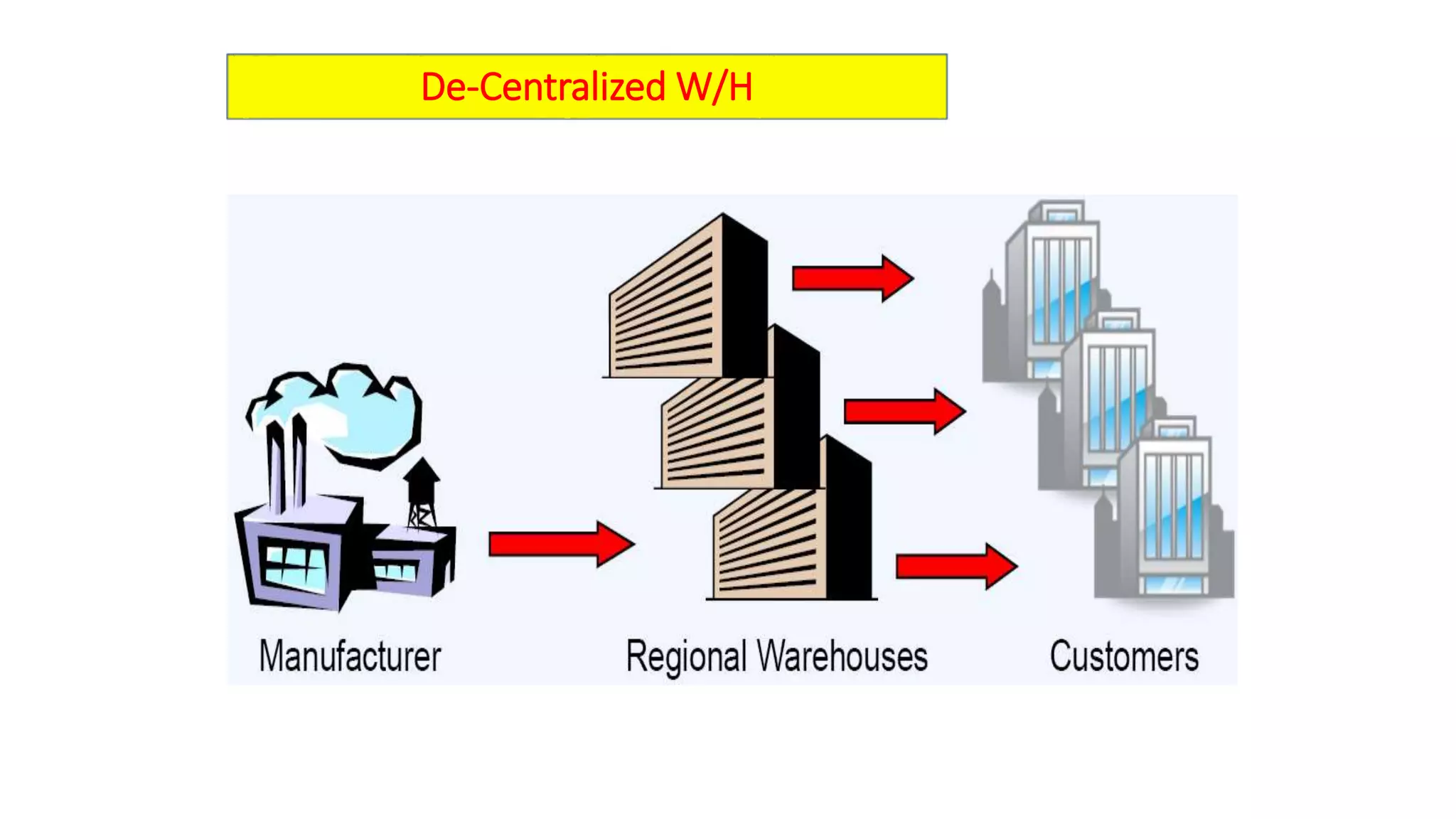

Warehousing involves the storage and distribution of inventory and materials. The document discusses different types of warehouses including private warehouses owned by individual companies, public warehouses that provide storage to multiple clients, and contract warehouses that combine aspects of private and public operations. Key functions of warehousing include receiving, storing, and issuing inventory as well as coordinating materials flow. The benefits of warehousing include consolidation of shipments, production support, and risk reduction through insurance of stored goods. Warehouses play an important role in supply chain management and distribution.