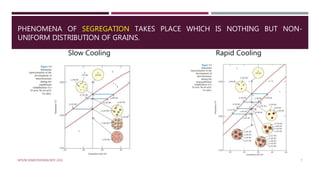

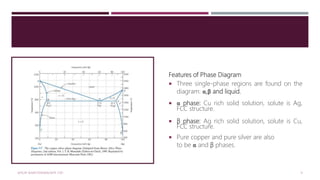

The document describes slow cooling and rapid cooling of an isomorphous alloy using a Cu-Ni system. For slow cooling, the alloy solidifies completely with a uniform composition along the solidus line. For rapid cooling, solidification takes longer and is incomplete, resulting in segregation of grains with non-uniform composition. The document also describes a binary eutectic system using Cu-Ag, which has three single-phase regions (α, β, liquid), limited solid solubility, and a eutectic reaction that occurs at a single temperature and composition.

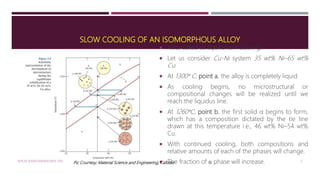

![ At 1250°C, point c, the compositions of the liquid

and α phases are 32 wt% Ni–68 wt% Cu [L(32 Ni)]

and 43 wt% Ni–57 wt% Cu [ (43 Ni)].

The solidification process is virtually complete

at1220°C about point d; the composition of the

solid is approximately 35 wt% Ni–65 wt% Cu.

Upon crossing the solidus line, this remaining

liquid solidifies; the final product then is a

polycrystalline -phase solid solution that has a

uniform 35 wt% Ni–65 wt% Cu composition at

point e.

MTE/III SEMESTER/MSE/MTE 2101 3

Pic Courtesy: Material Science and Engineering, Callister.](https://image.slidesharecdn.com/lecture17-170203082146/85/Two-Component-System-3-320.jpg)

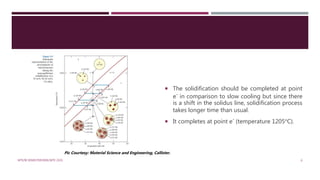

![RAPID COOLING OF AN ISOMORPHOUS ALLOY

Also, called as Non Equilibrium Cooling.

Let us consider Cu-Ni system 35 wt% Ni–65

wt% Cu.

At 1300° C; point a´, the alloy is completely

liquid.

As cooling begins, no microstructural or

compositional changes will be realized until we

reach the liquidus line.

At point b´, (approximately 1260°C), α-phase

particles begin to form, which, from the tie line

constructed, have a composition of 46 wt% Ni–

54 wt% Cu [ (46 Ni)].

MTE/III SEMESTER/MSE/MTE 2101 4Pic Courtesy: Material Science and Engineering, Callister.](https://image.slidesharecdn.com/lecture17-170203082146/85/Two-Component-System-4-320.jpg)

![ Upon further cooling to point c´ (about 1260°C

), the liquid composition has shifted to 29 wt%

Ni–71 wt% Cu; furthermore, at this temperature

the composition of the αphase that solidified is

40 wt% Ni–60 wt% Cu [ (40 Ni)].

Because of the rapid cooling, the solidus line

shifted (indicated in dashed line) and solid

composition has increased.

At point d´ (temperature 1220°C), the

solidification should complete but there is still

little amount of liquid is left.

MTE/III SEMESTER/MSE/MTE 2101 5

Pic Courtesy: Material Science and Engineering, Callister.](https://image.slidesharecdn.com/lecture17-170203082146/85/Two-Component-System-5-320.jpg)

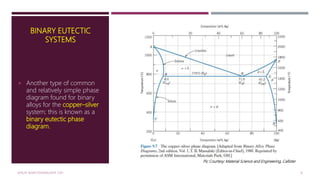

![Features of Phase Diagram (Contd.)

The solubility in each of these solid phases is

limited, in that at any temperature below line

BEG only a limited concentration of silver will

dissolve in copper (for the α phase) similarly

copper in silver (for the β phase).

The solubility limit for the α phase

to the boundary line, labelled CBA, between

the α/(α+β) and α/(α+L) phase regions; it

increases with temperature to a maximum [8.0

wt% Ag at 779°C] at point B and decreases

back to zero at the melting temperature of

pure copper, point A 1085°C.

MTE/III SEMESTER/MSE/MTE 2101 10](https://image.slidesharecdn.com/lecture17-170203082146/85/Two-Component-System-10-320.jpg)