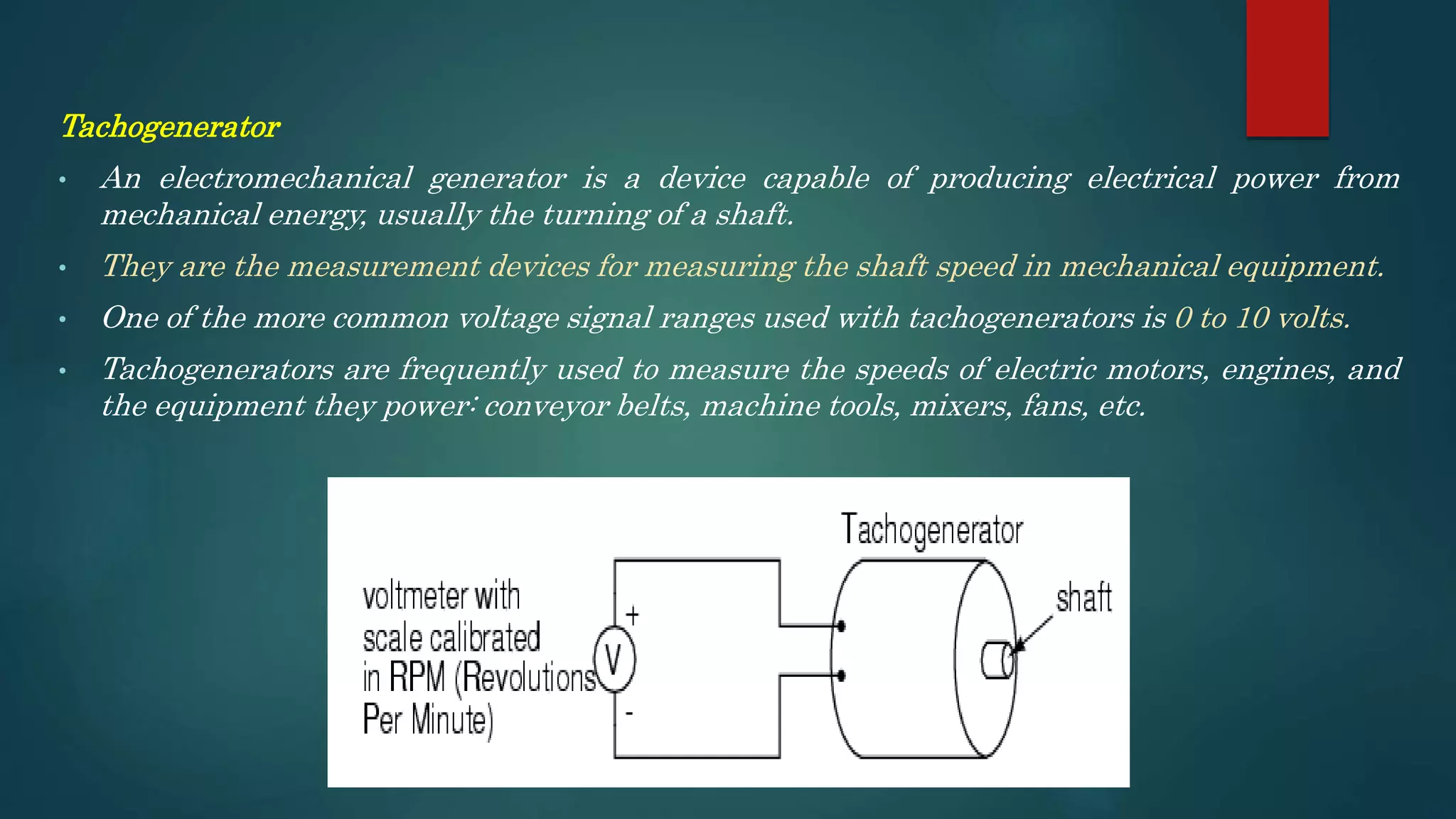

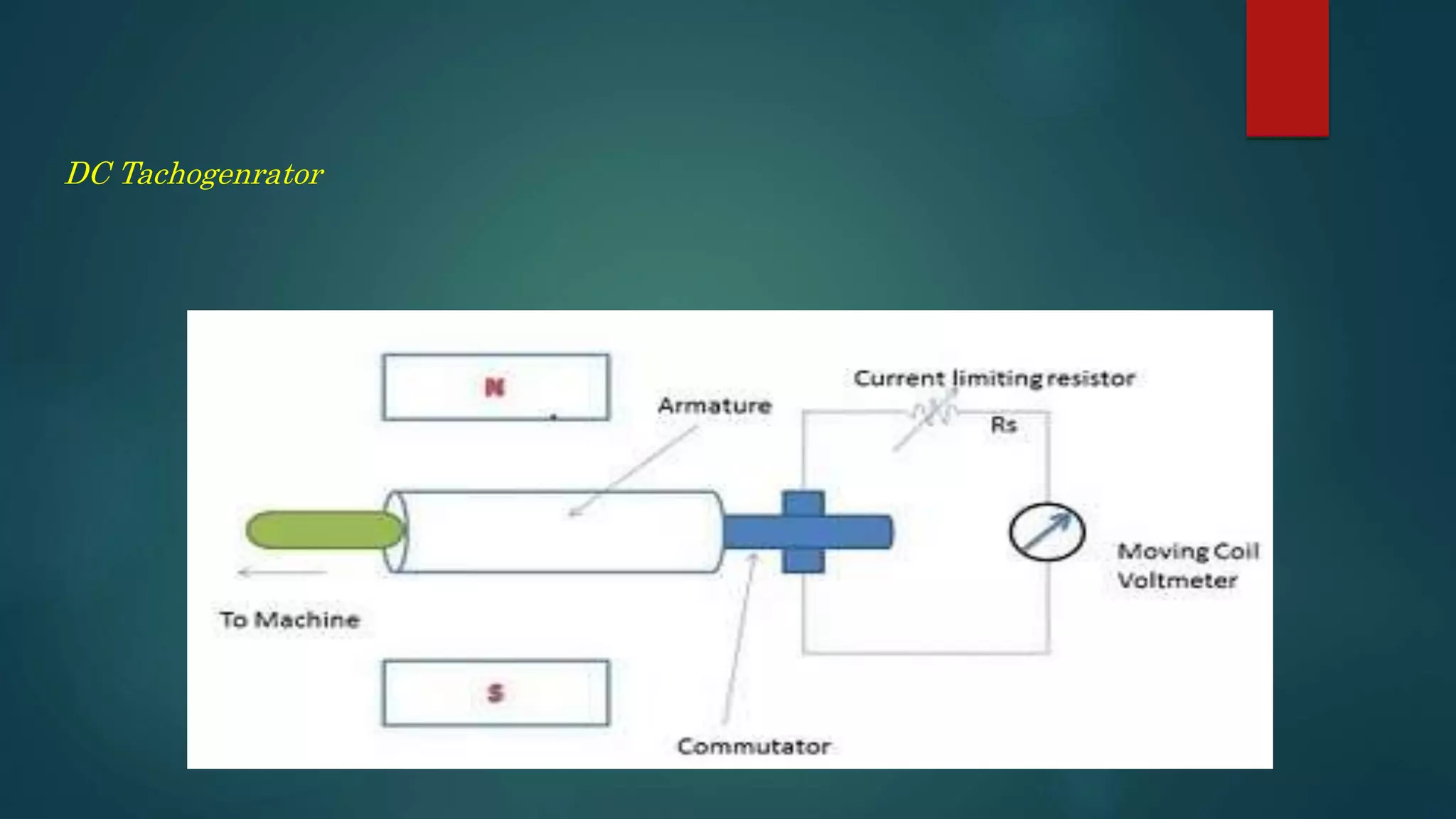

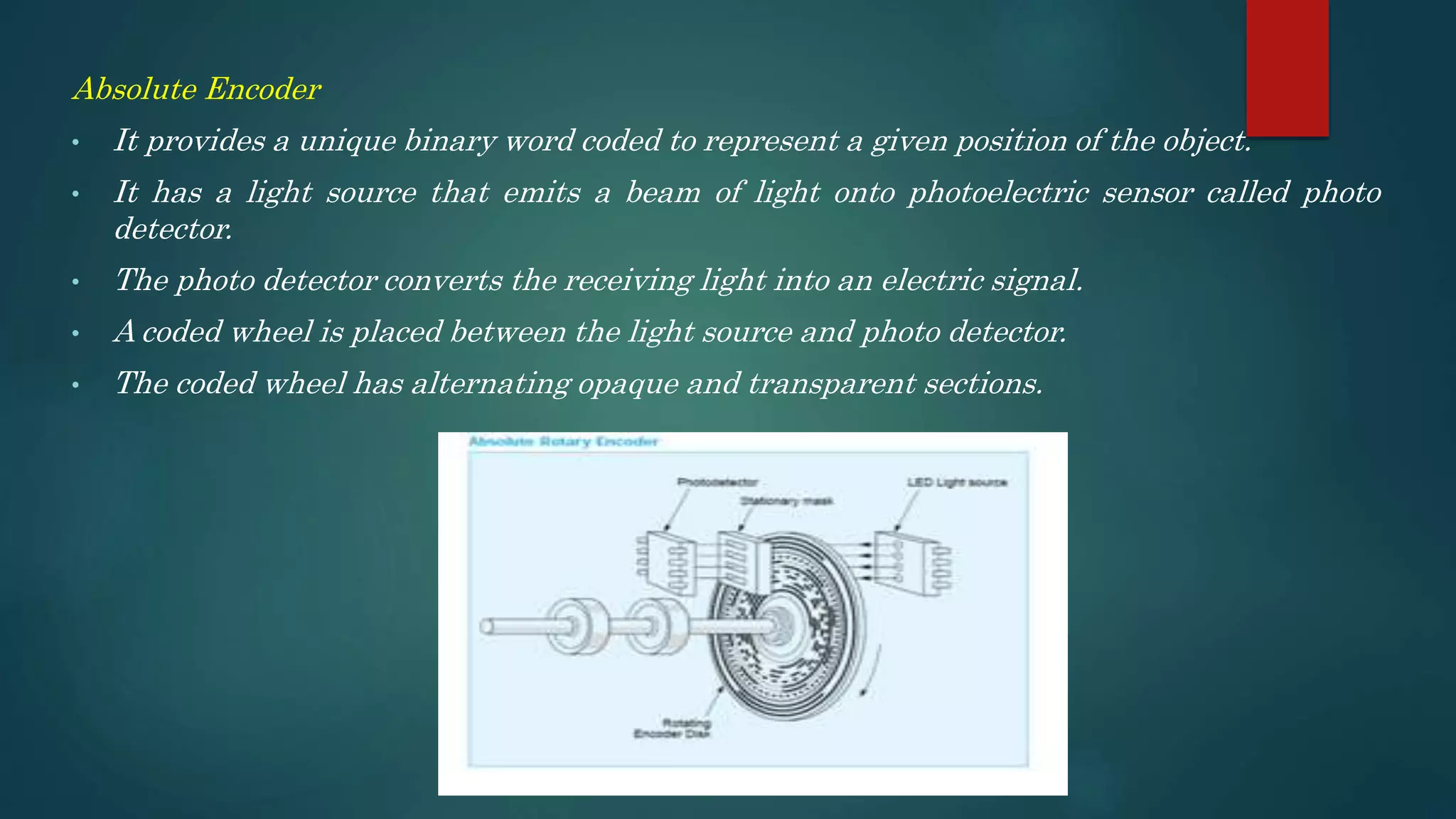

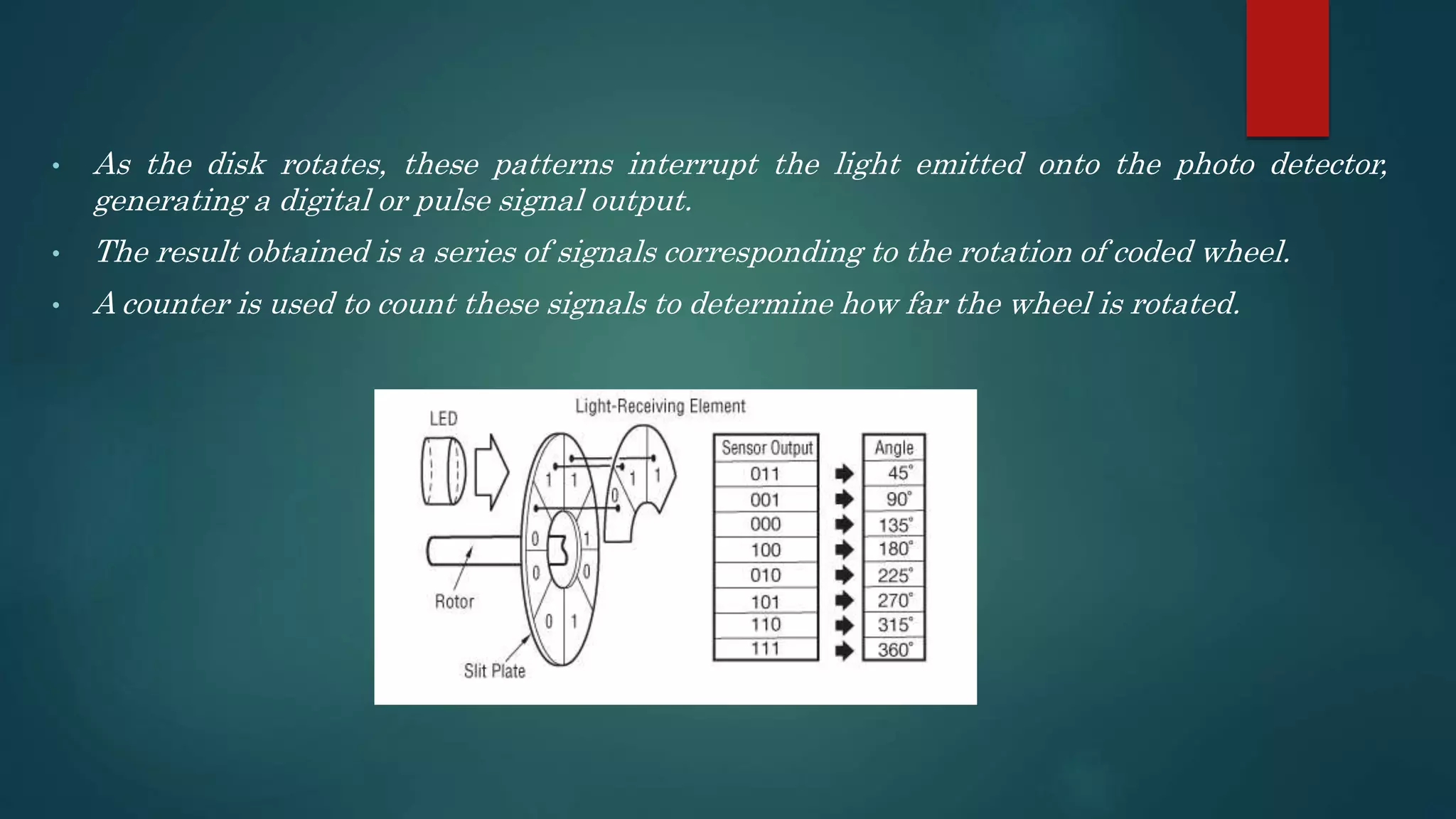

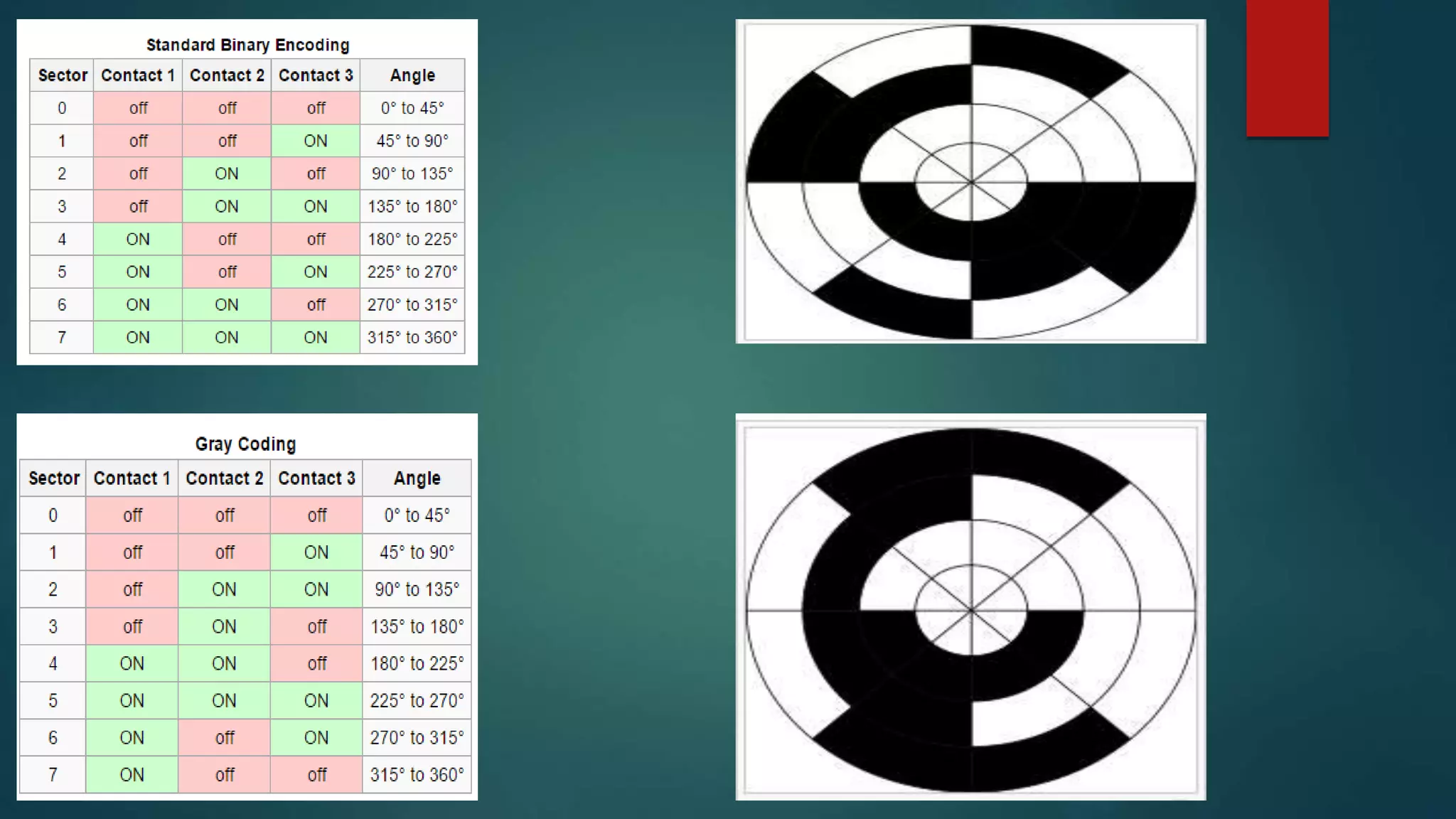

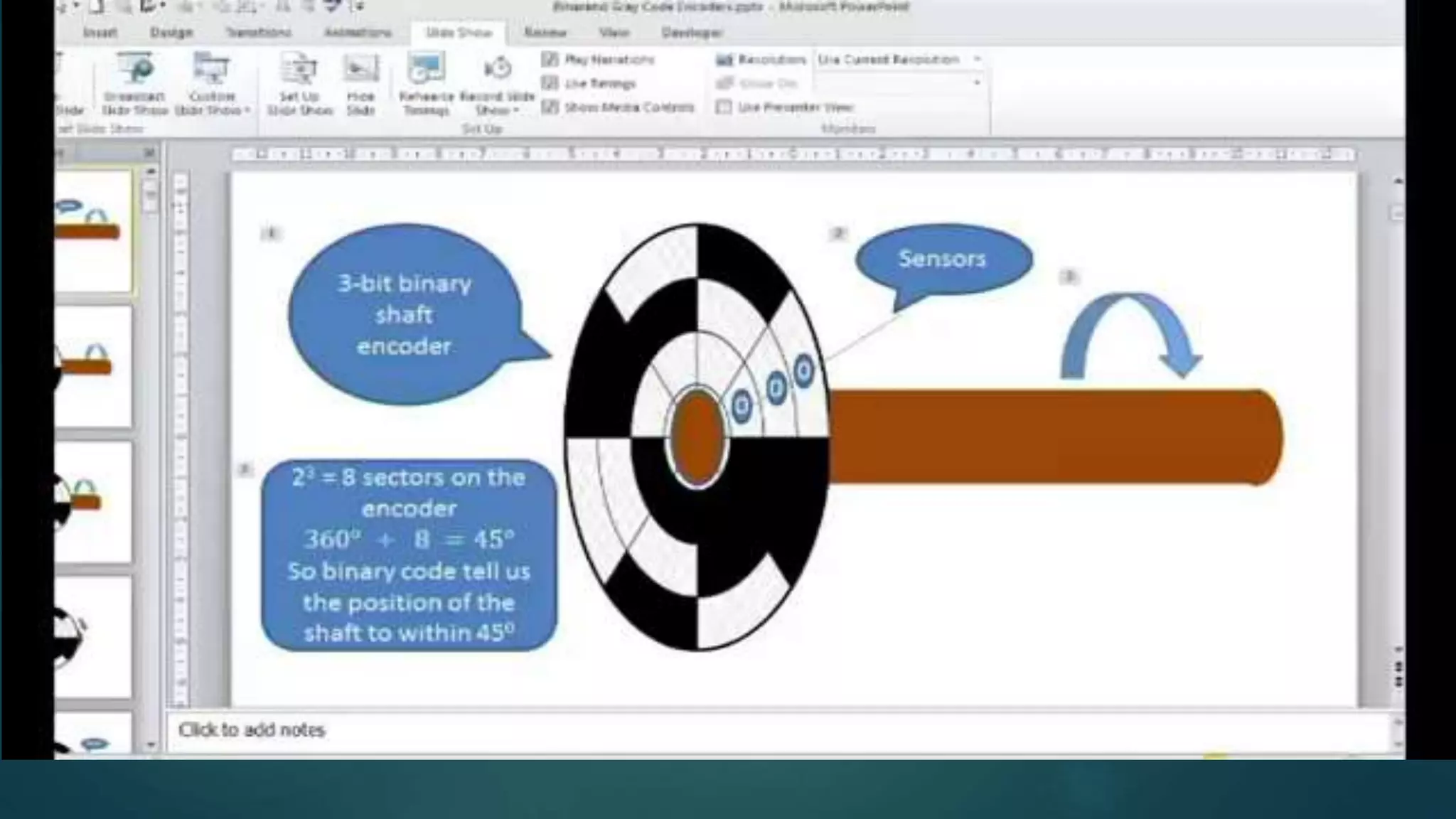

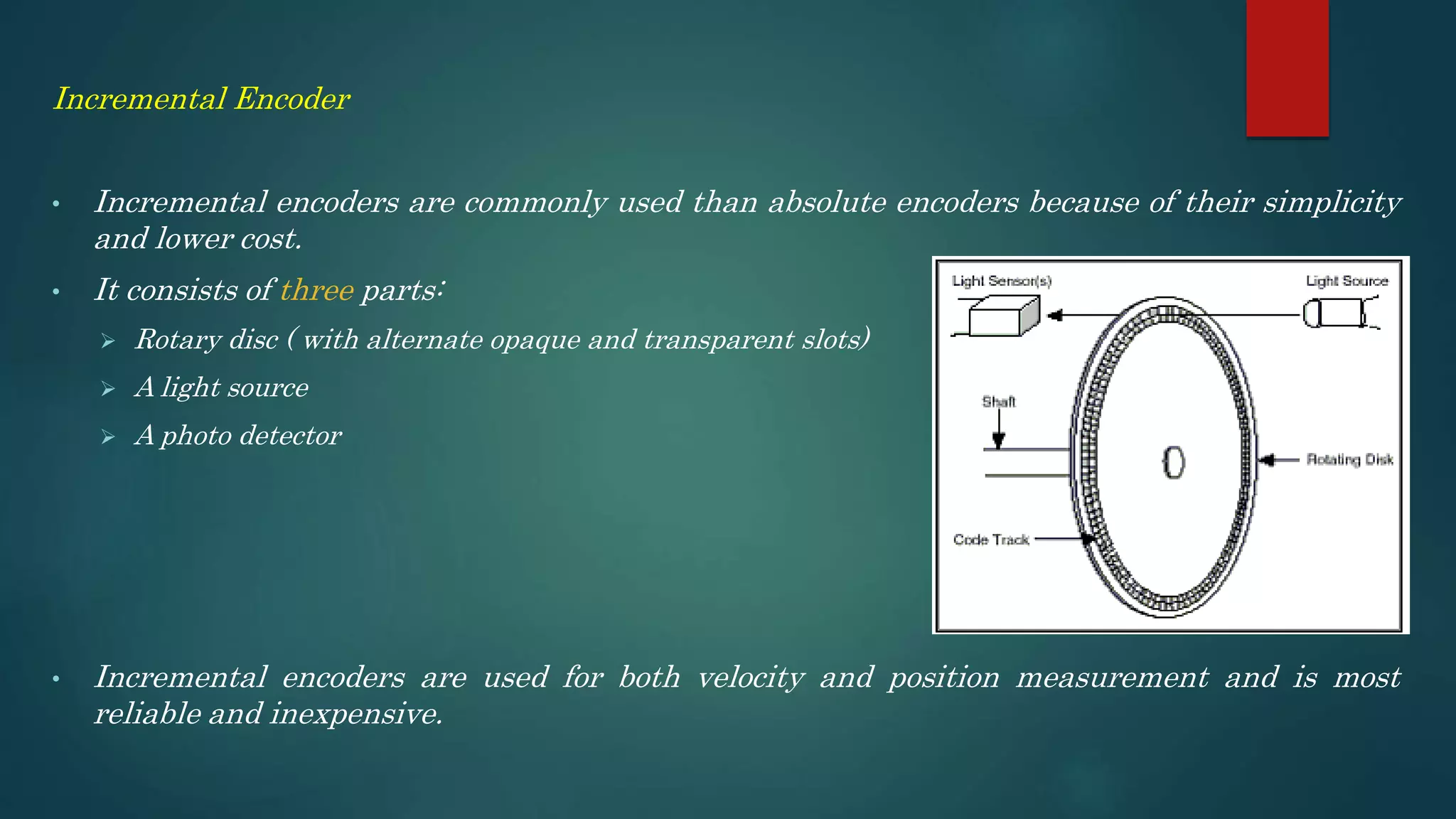

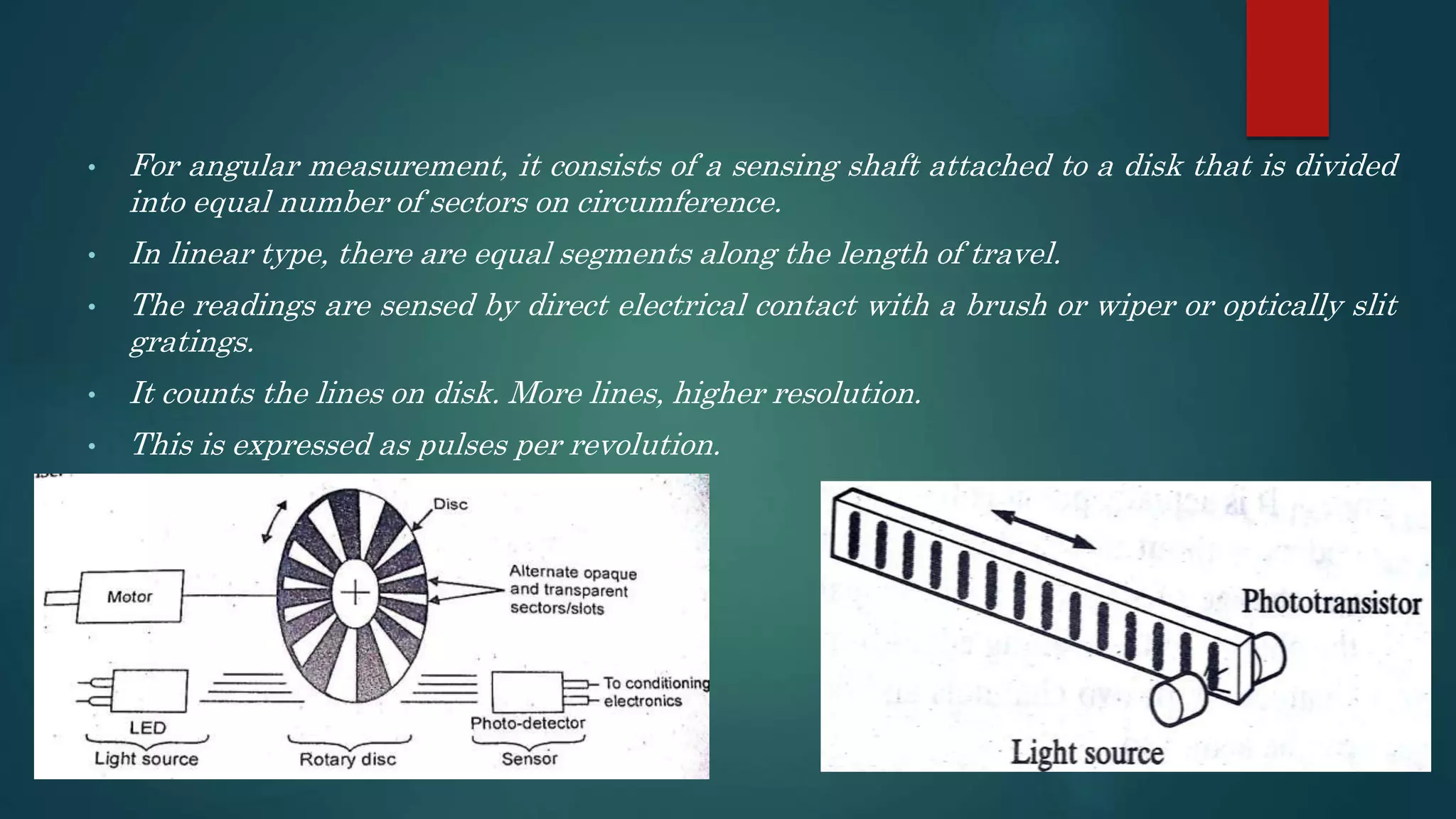

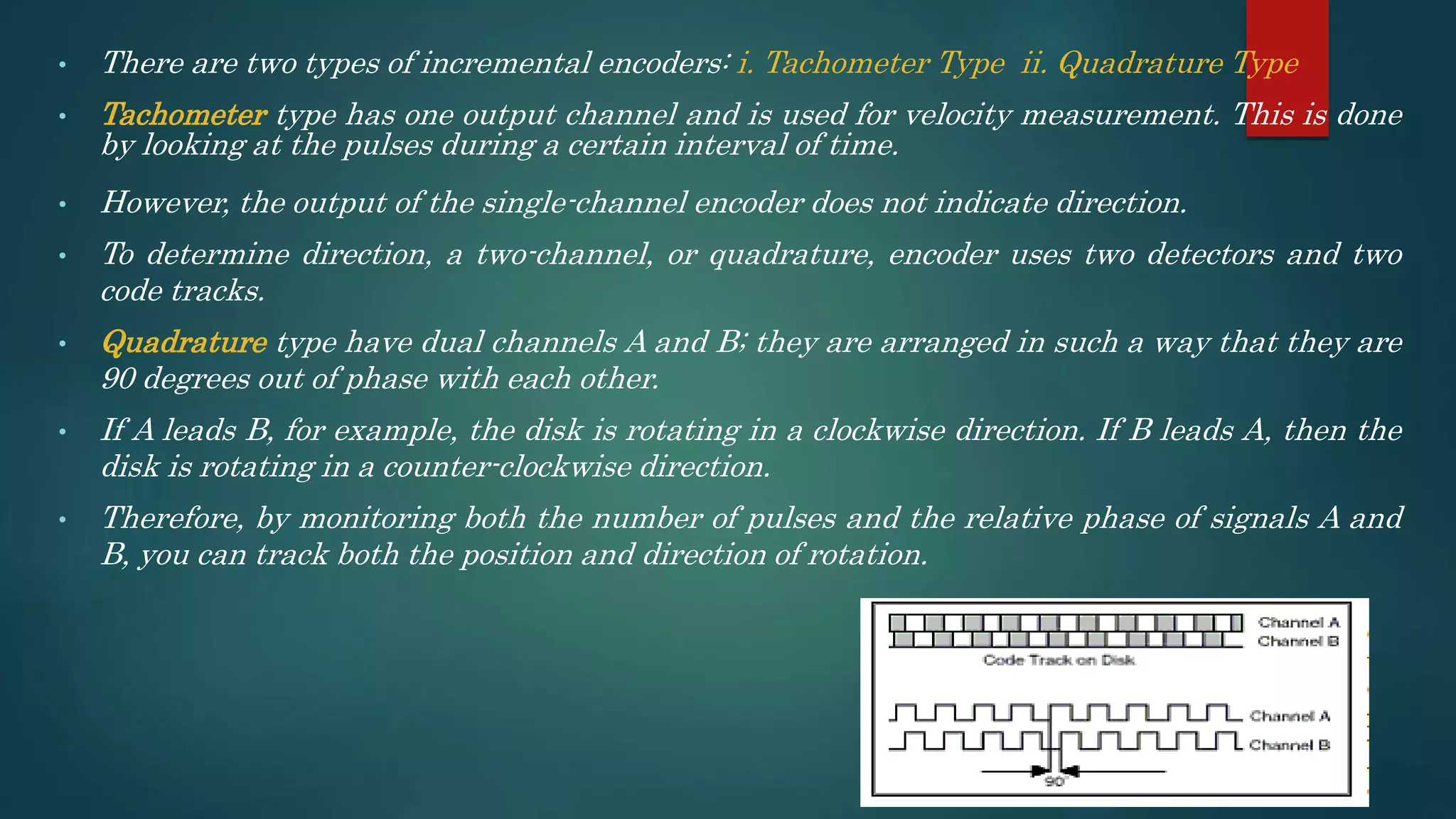

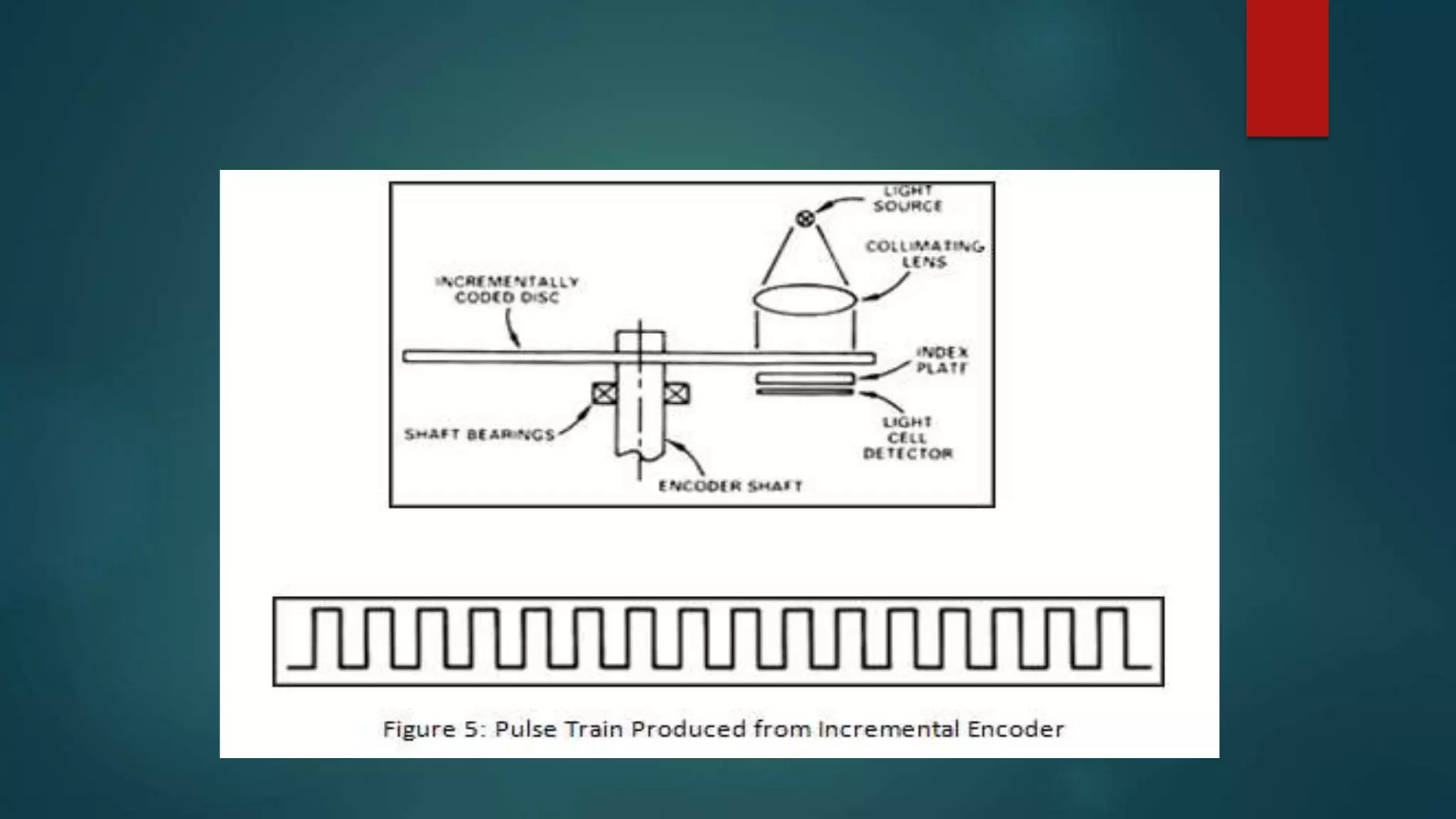

Tachogenerators and optical encoders are used to measure rotational movement. Tachogenerators use the principle that a voltage is induced when there is relative motion between a magnetic field and conductor. Optical encoders have a light source and sensor that detect patterns on a rotating disk to provide a digital output proportional to angular position. There are two main types: absolute encoders uniquely represent a given position, while incremental encoders count lines to determine position but not uniquely.