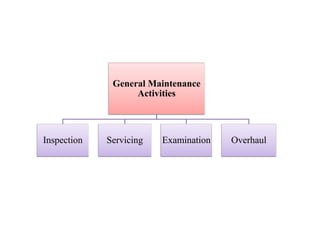

This document discusses maintenance and installation of circuit breakers. It outlines two types of maintenance: corrective maintenance which is done after failure, and preventive maintenance which is done on a schedule to prevent failures. Preventive maintenance is recommended for switchgear. The document then details 13 steps for circuit breaker maintenance including inspection, cleaning, drying, checking contacts and mechanisms. It concludes with 13 steps for circuit breaker installation including foundation preparation, assembly, testing, and energization.