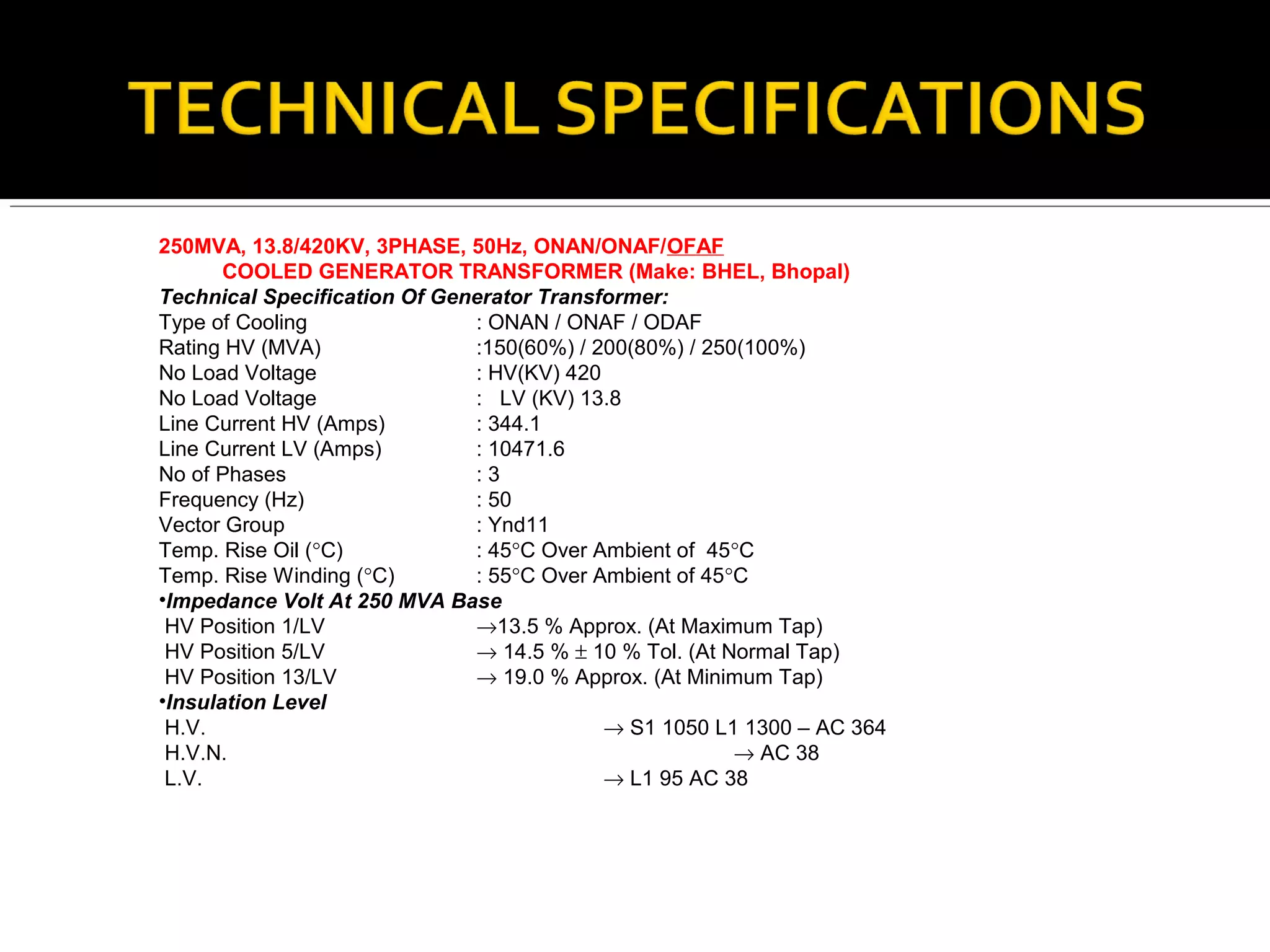

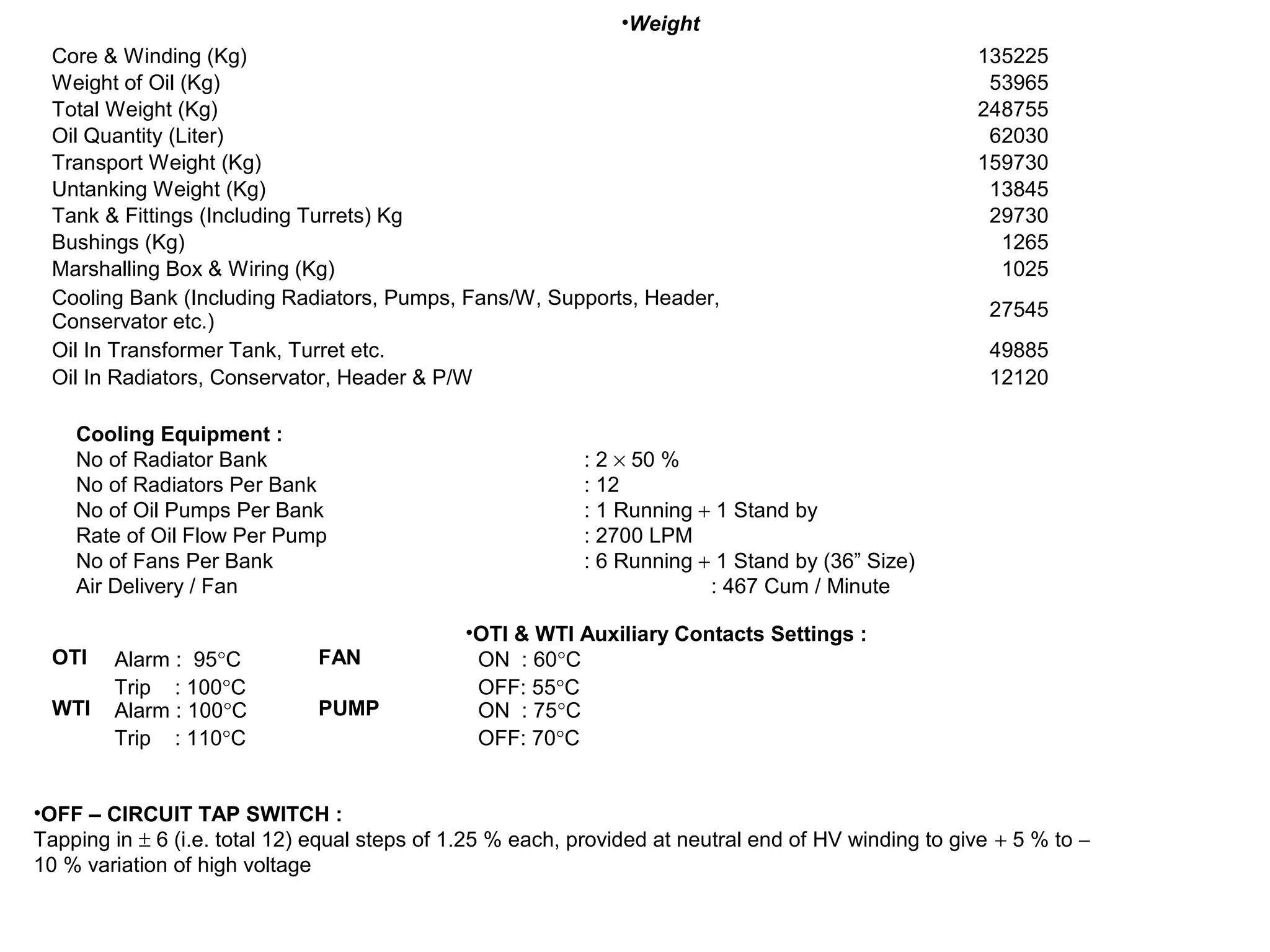

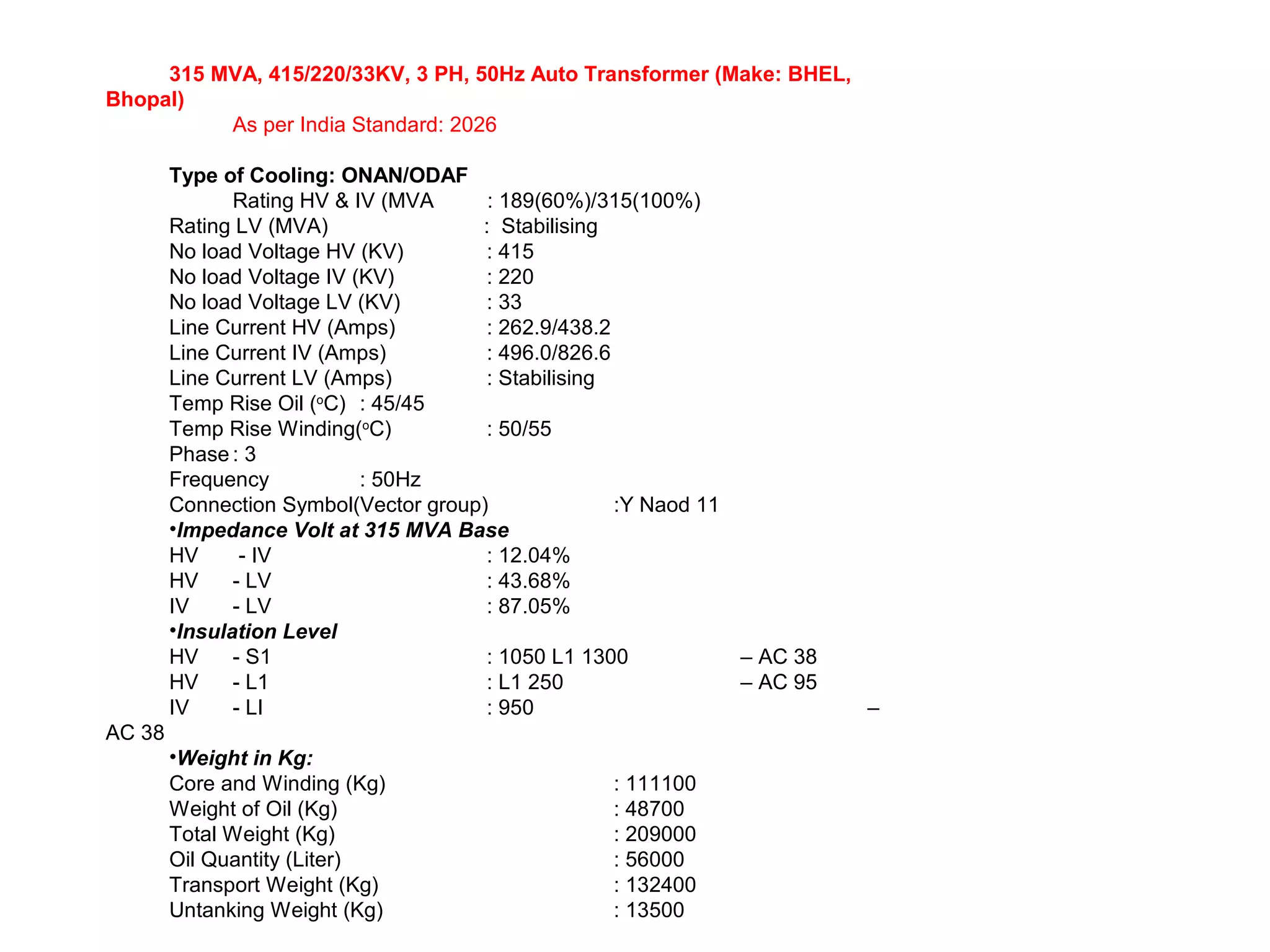

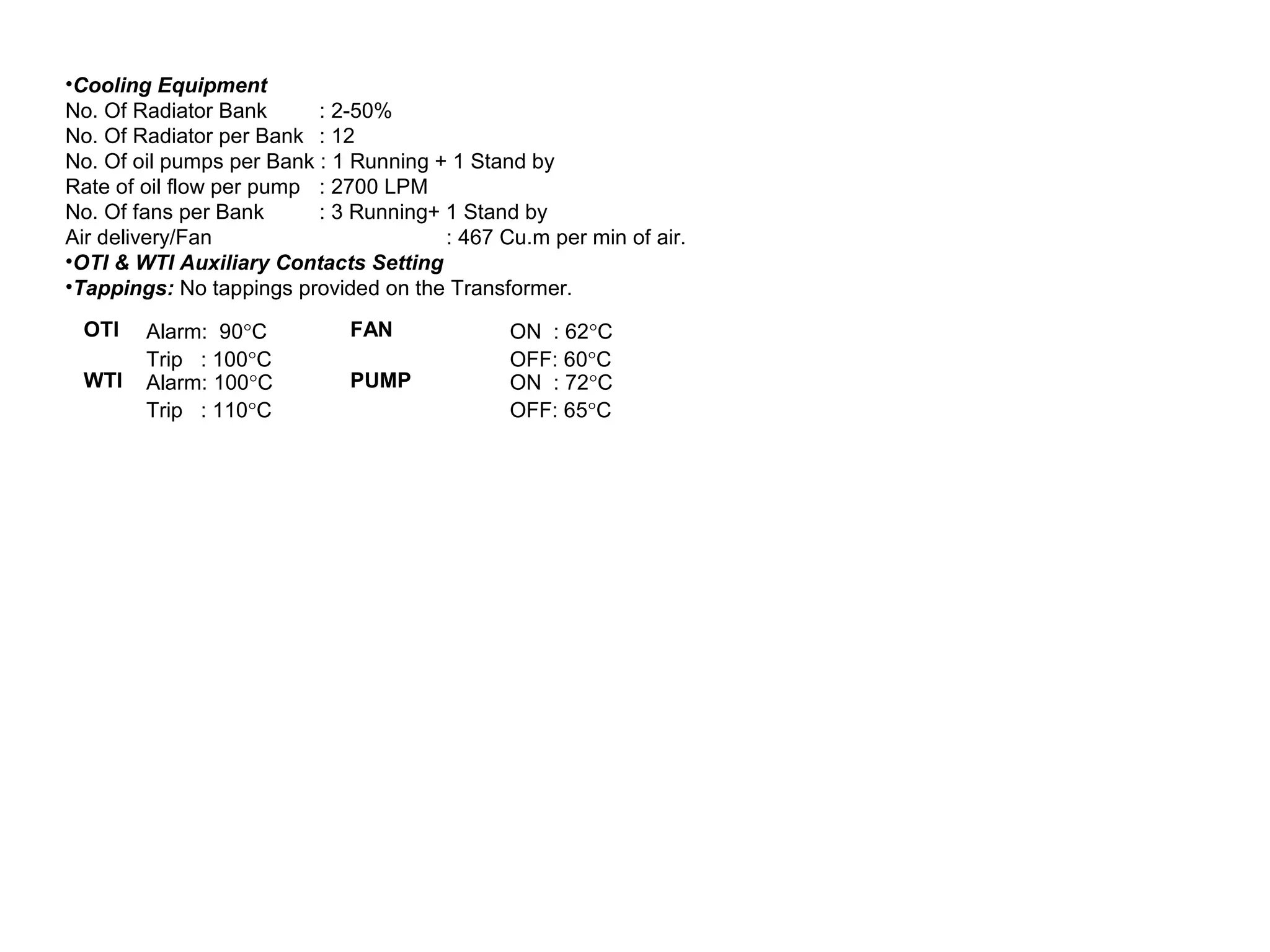

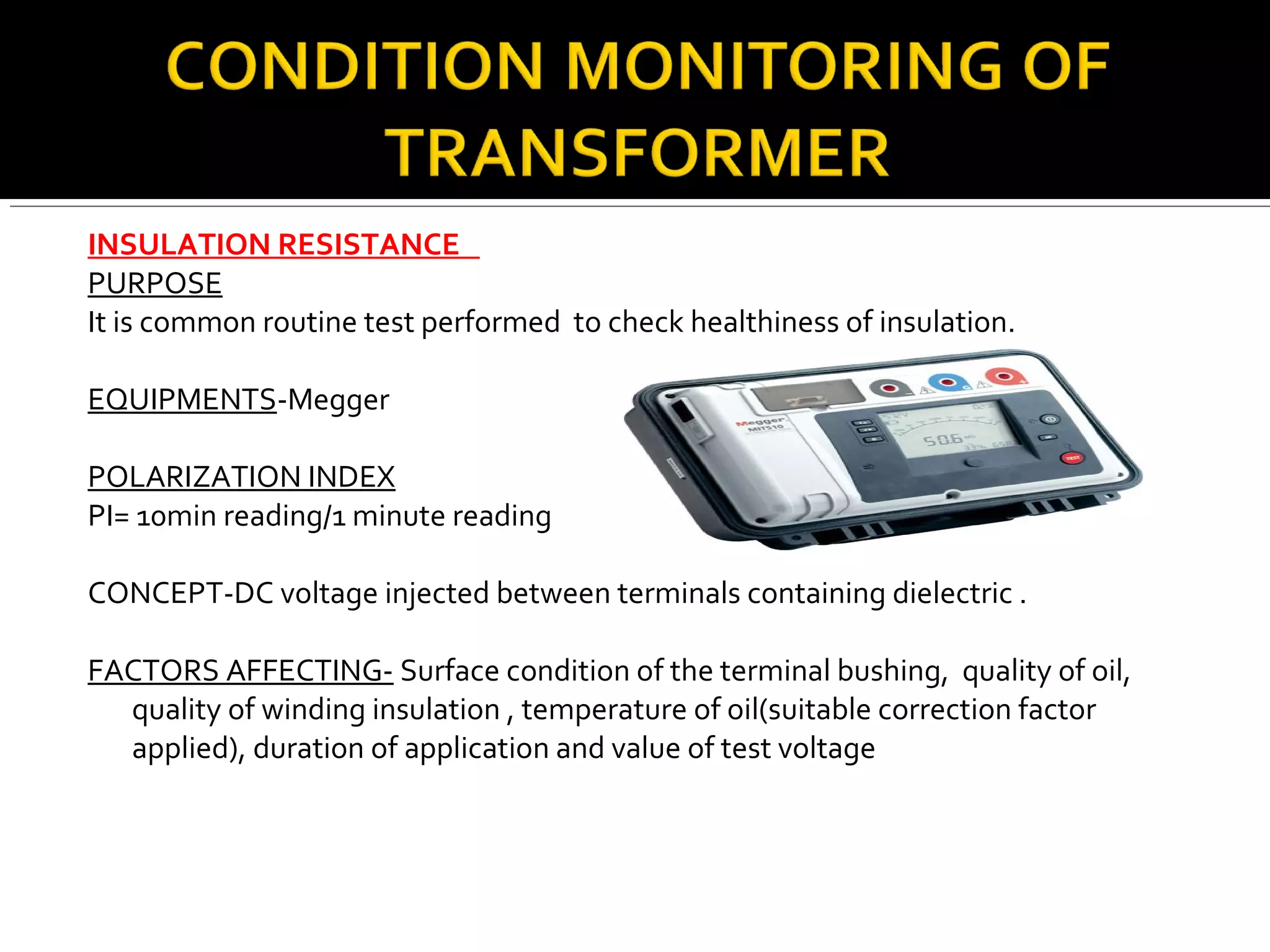

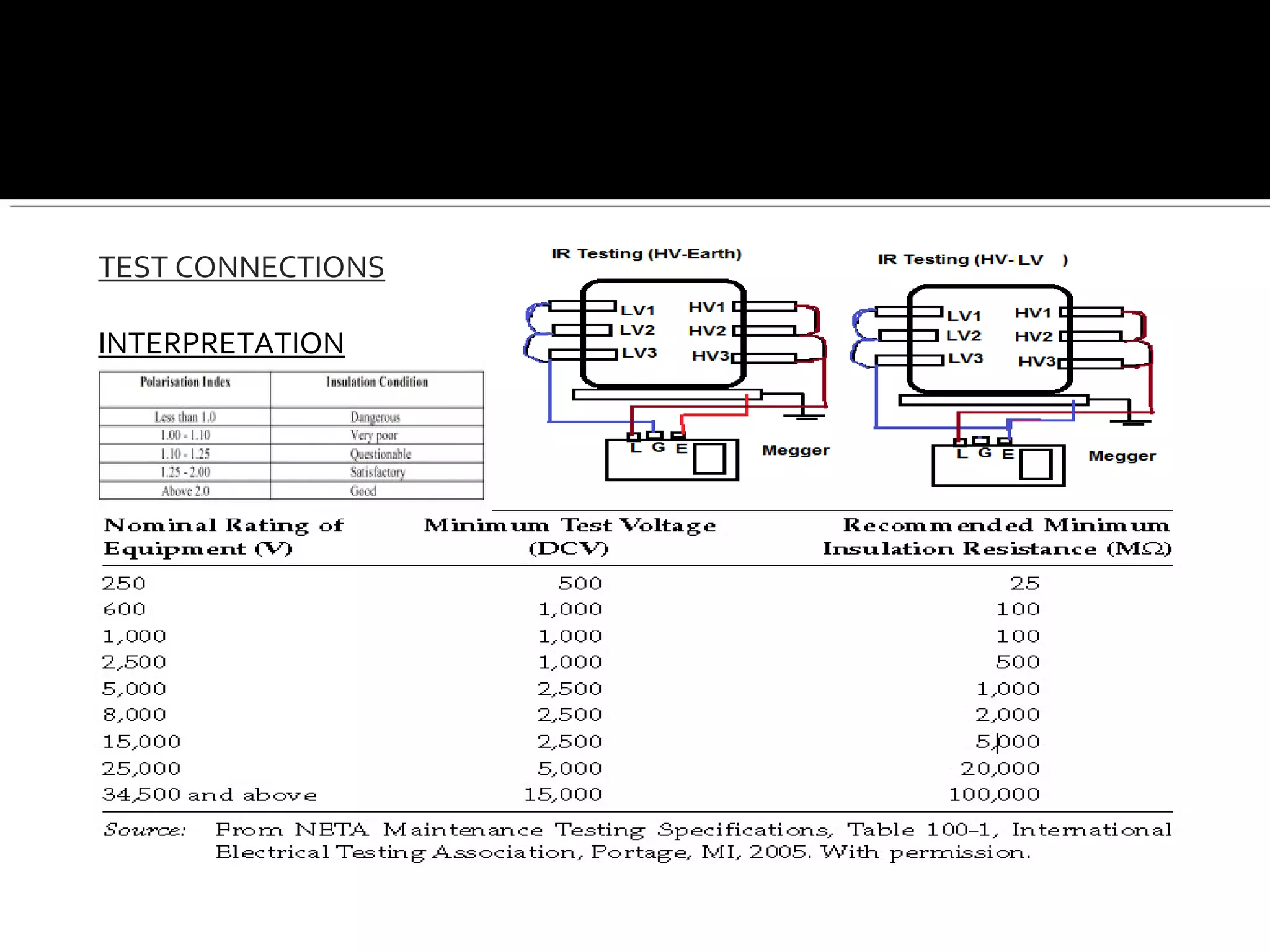

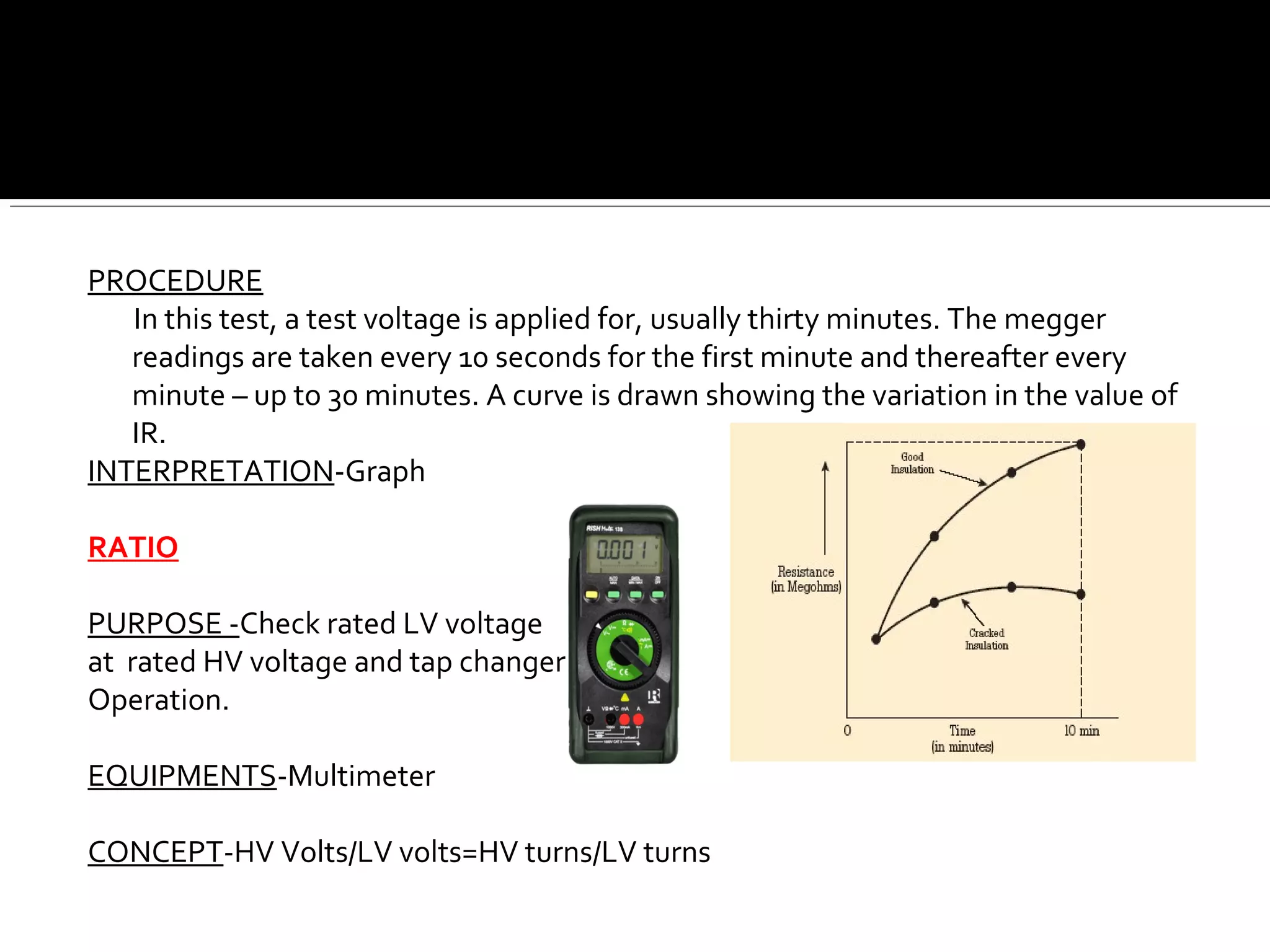

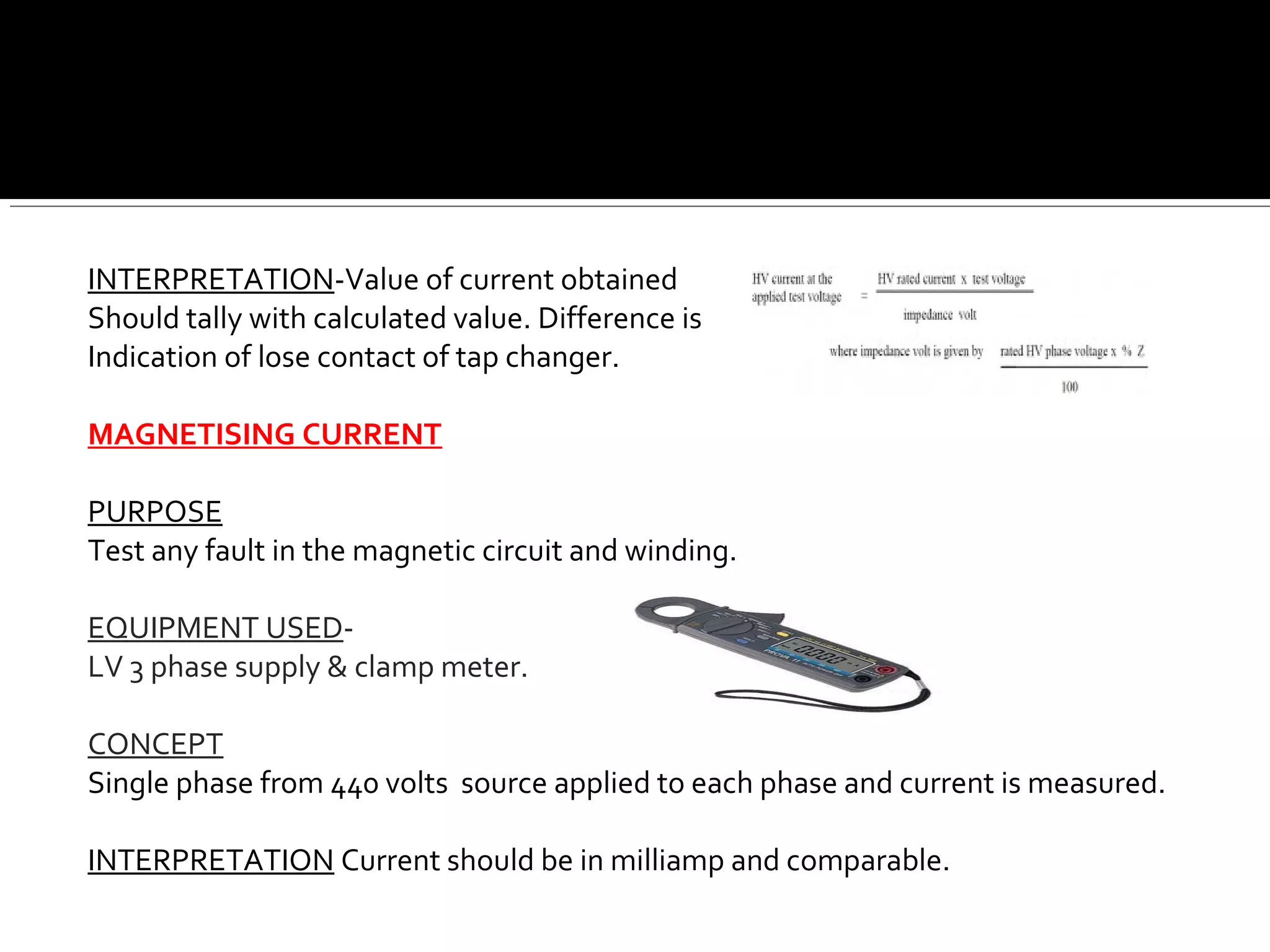

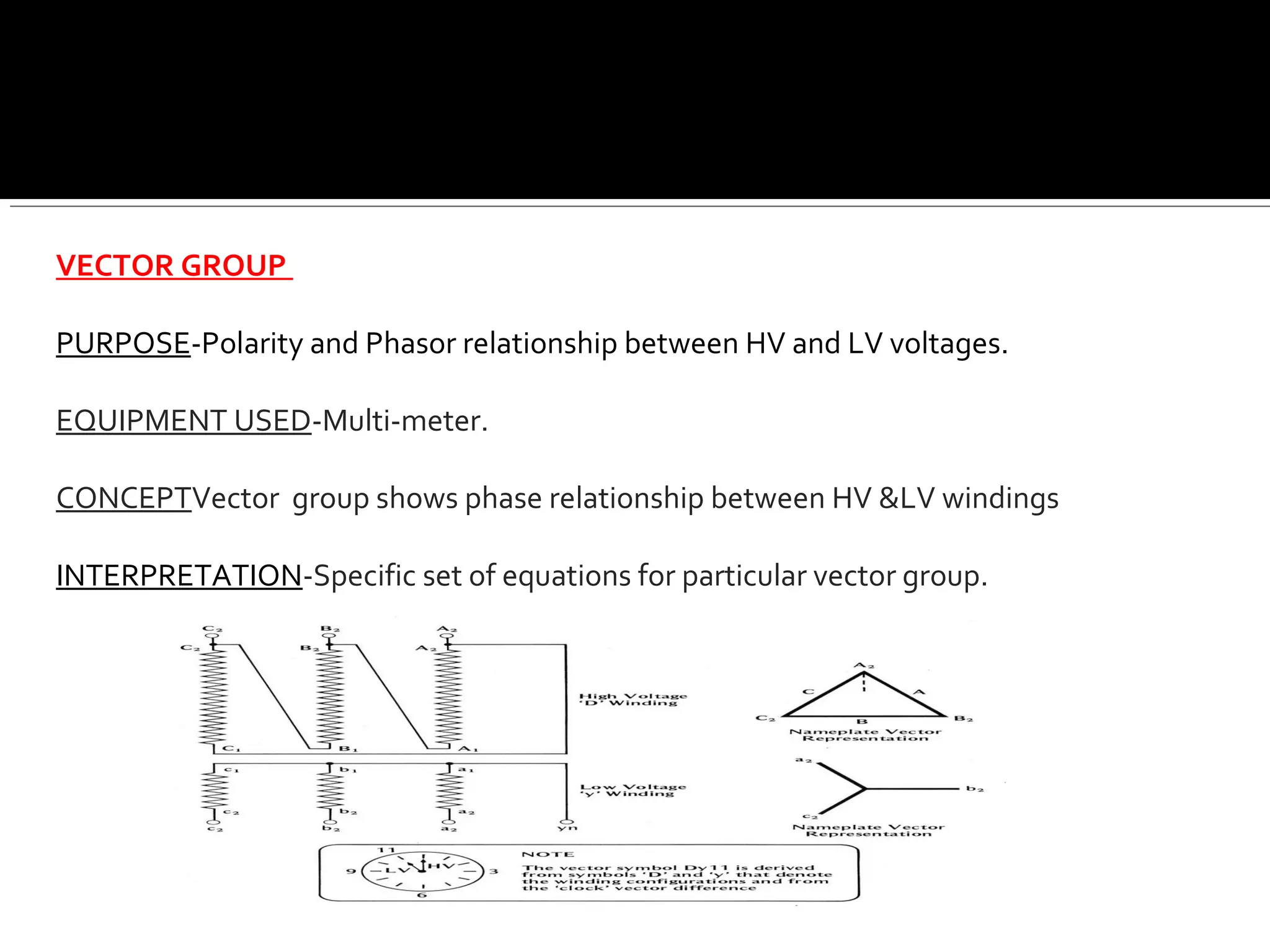

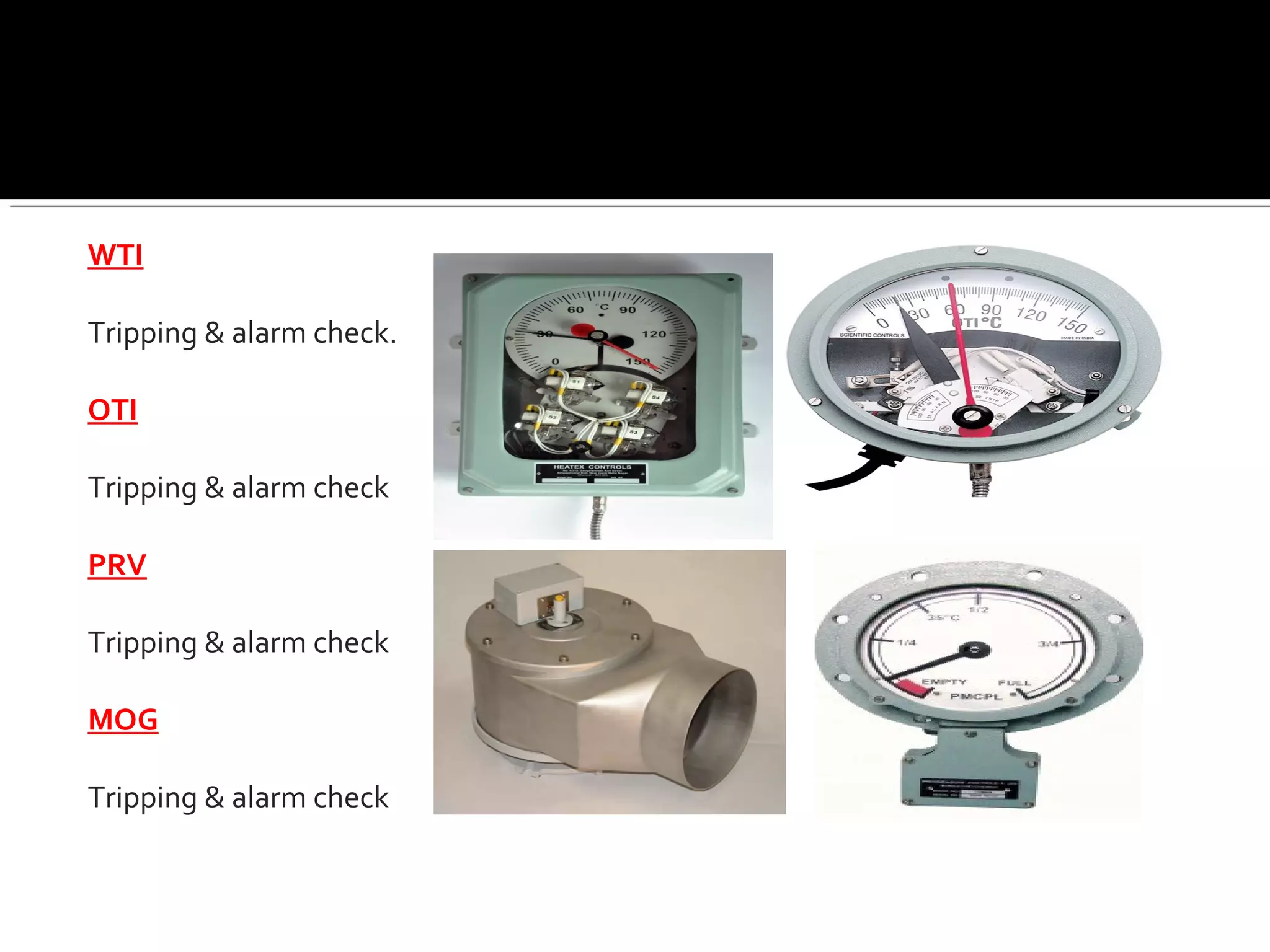

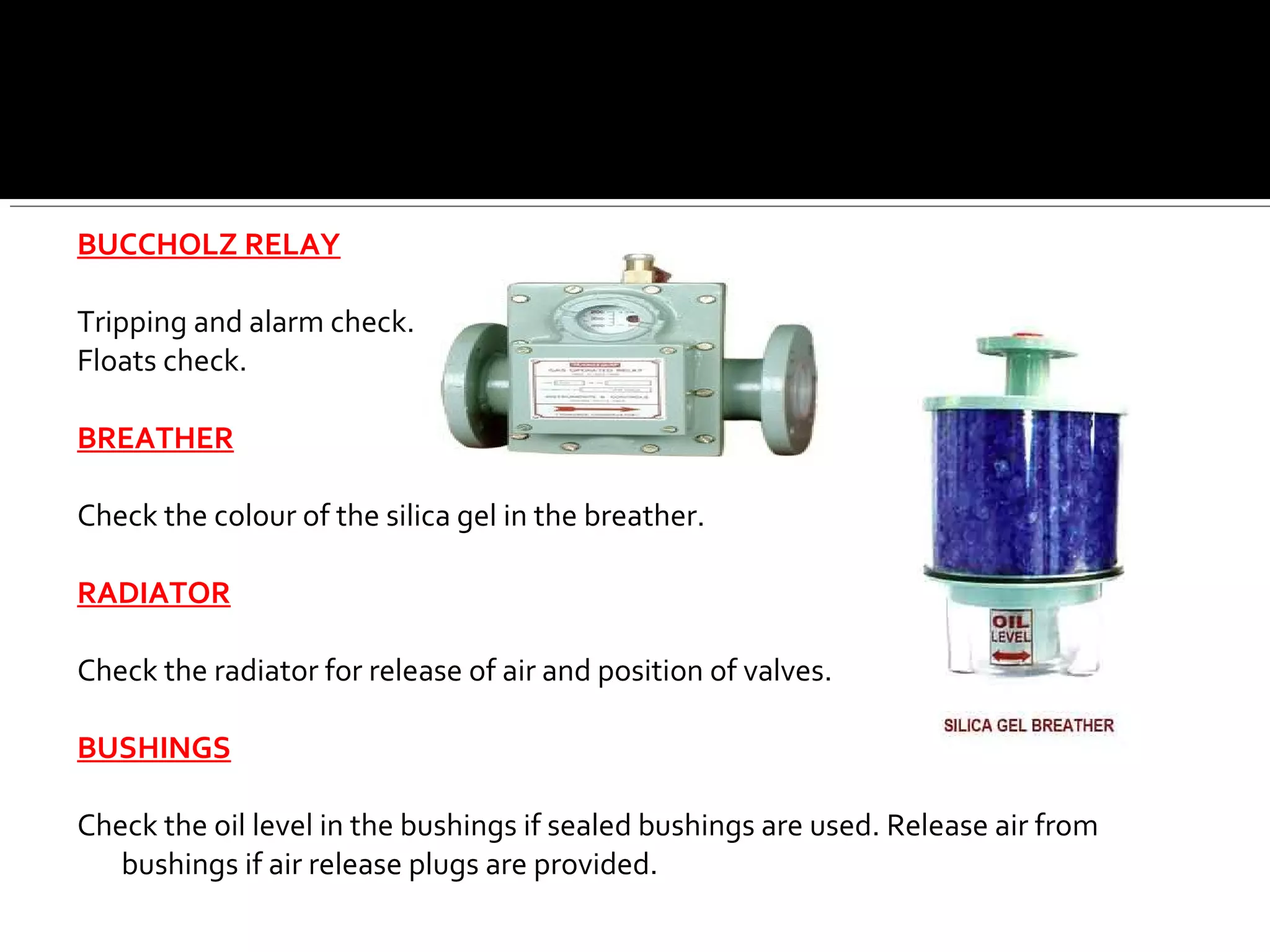

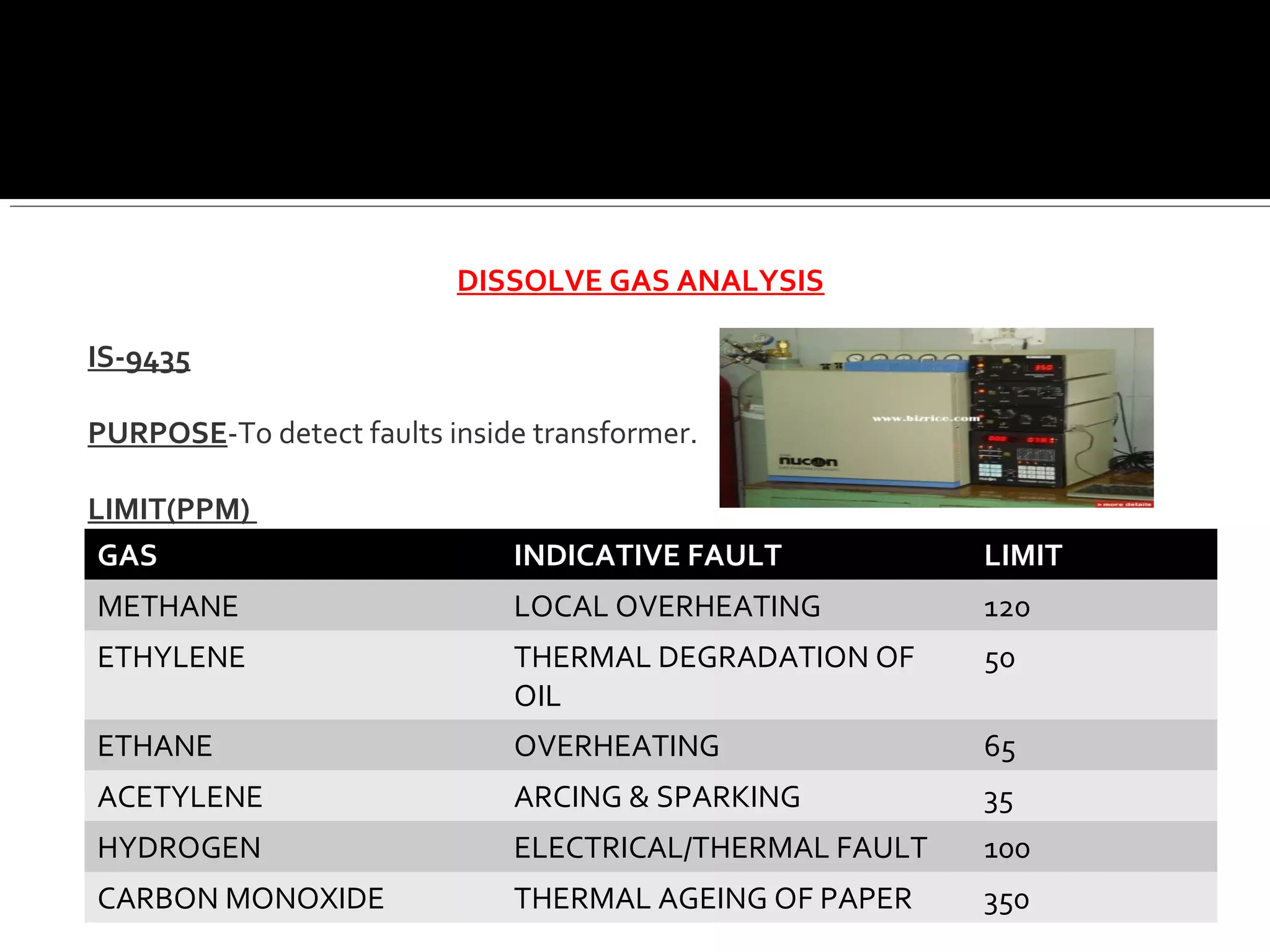

The document provides comprehensive technical specifications for a 250 MVA generator transformer and a 315 MVA auto transformer from BHEL, detailing their cooling types, ratings, and various electrical parameters. It includes information on insulation levels, weight, oil quantities, and monitoring parameters for insulation health and transformer condition, as well as alarms and alarms check procedures. Additionally, the document outlines maintenance practices and testing methods essential for ensuring the reliability and operational safety of these transformers.