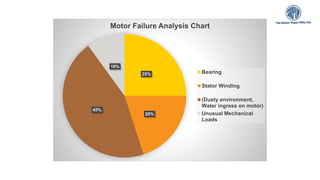

This document discusses causes of motor failures and preventative measures. The main causes of motor failures are heat, power supply anomalies, dust contamination and water ingress, improper lubrication, and unusual mechanical loads. Condition monitoring parameters to watch include vibration, temperature, sounds, visual inspections, and maintenance records. Preventative maintenance includes cleaning, tightening, insulation resistance and winding resistance tests, visual inspections, and maintenance records. Motor testing analyzes insulation resistance, polarization index, winding resistance, inductance, tan delta, partial discharge, and other parameters to understand motor health and take preventative actions.