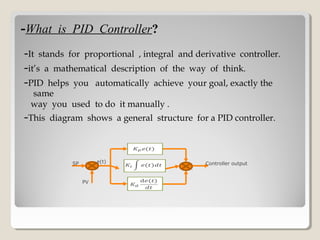

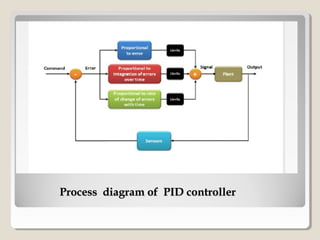

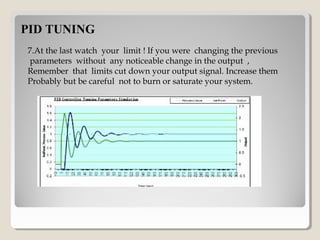

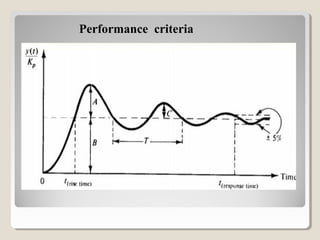

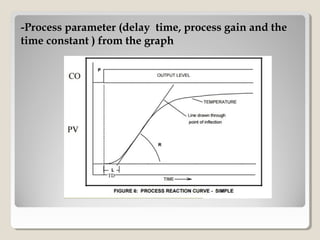

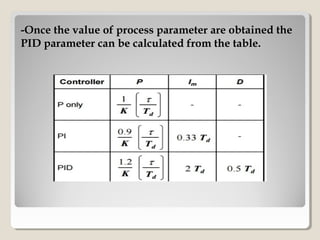

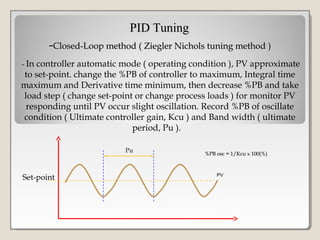

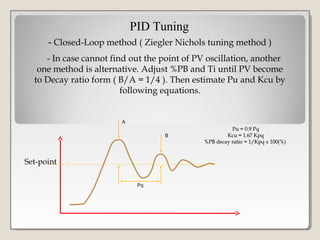

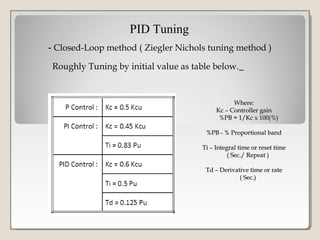

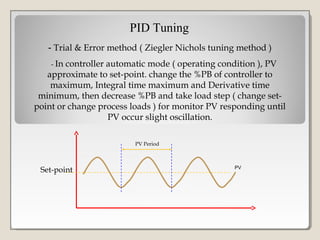

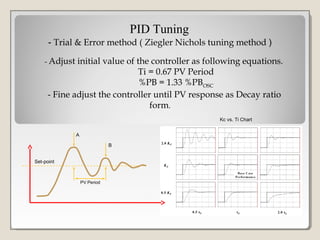

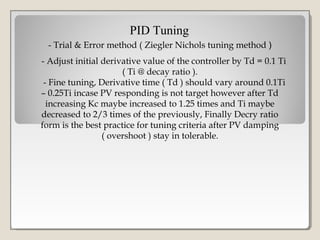

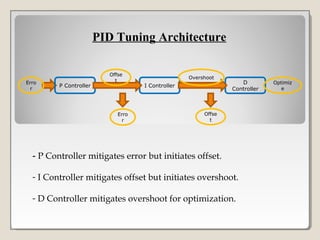

This document discusses PID controller tuning. It defines what a PID controller is and its components - proportional, integral and derivative terms. It describes three common methods for tuning PID parameters: Ziegler-Nichols open loop method which relates process parameters to controller parameters; closed loop Ziegler-Nichols method which introduces oscillations and varies parameters; and trial and error method starting with maximum proportional band and minimum other terms then adjusting. Performance criteria for tuning are listed as minimizing error, settling time, and overshoot.