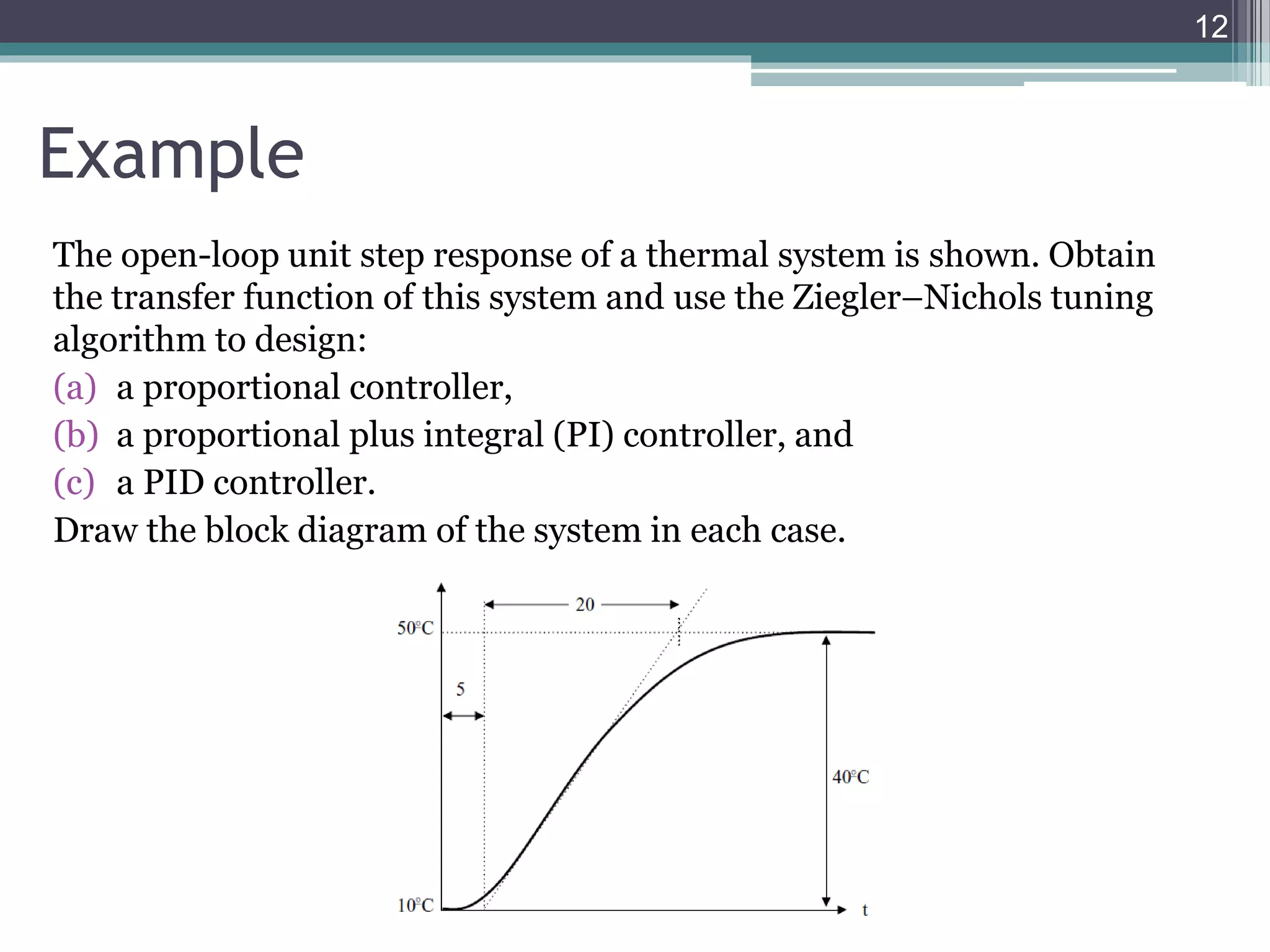

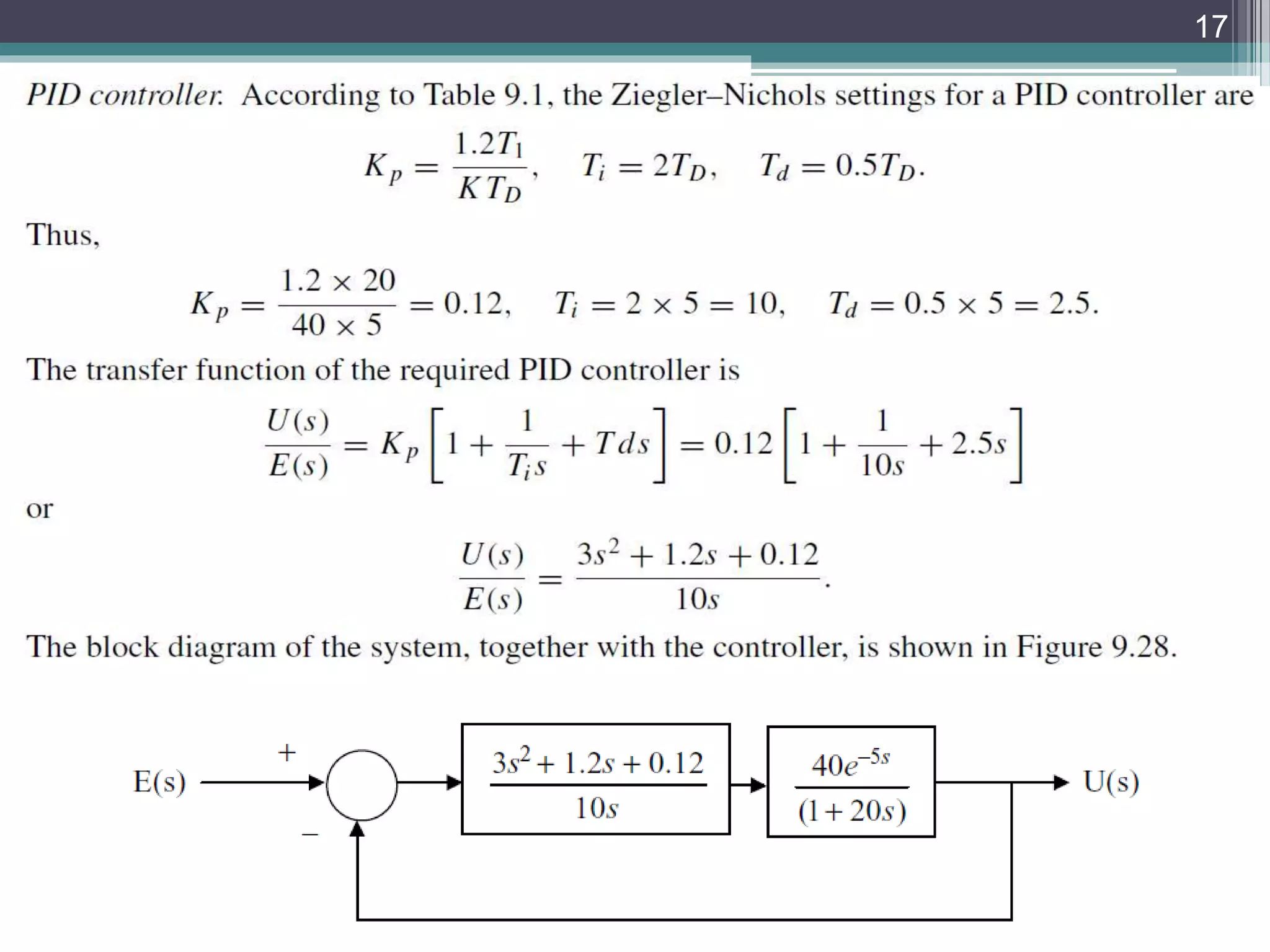

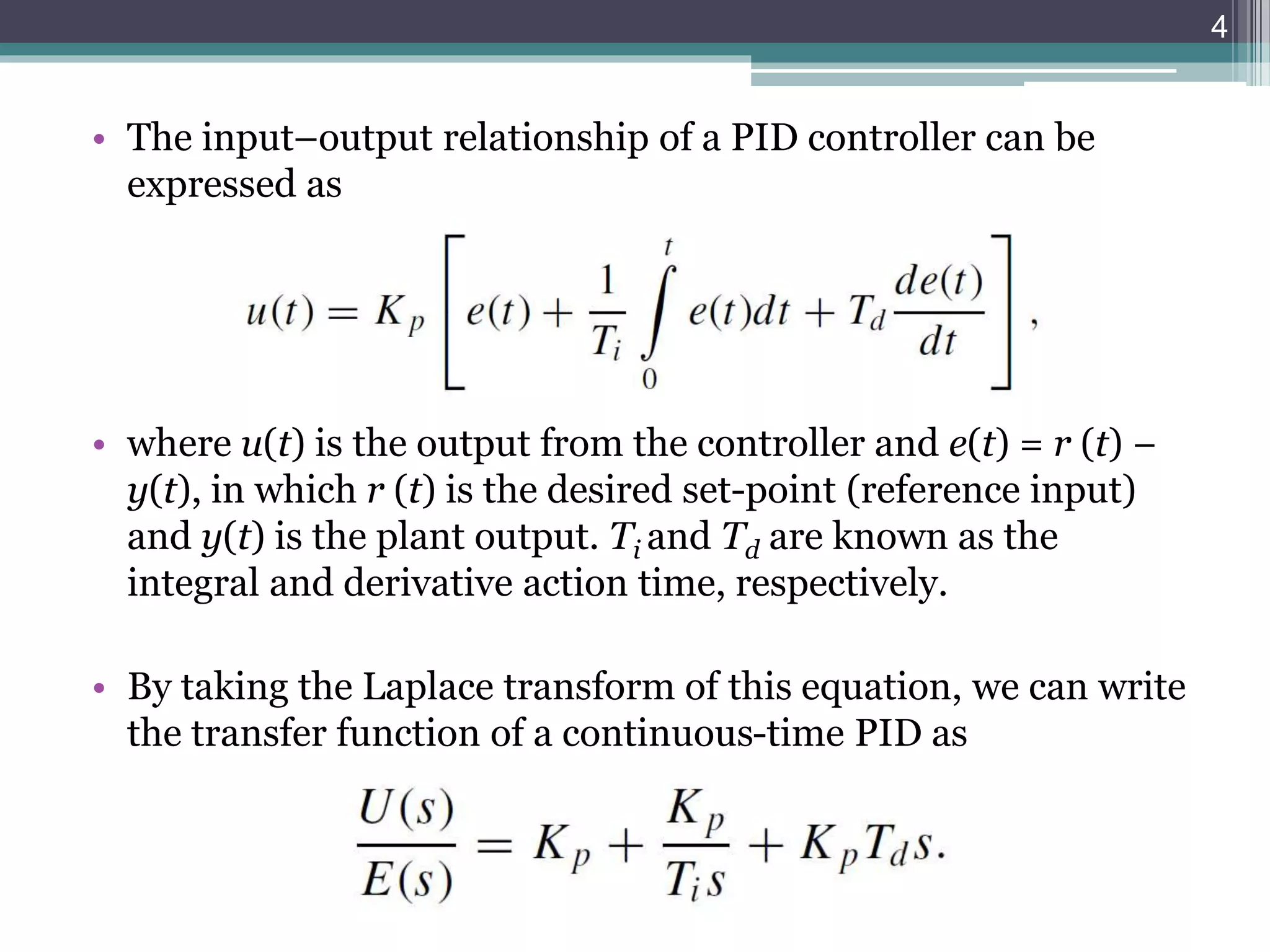

This document discusses PID (proportional-integral-derivative) controllers. It explains that PID controllers use three terms: proportional to the error, integral of the error, and derivative of the error. The document provides equations for continuous and discrete PID controllers. It also describes Ziegler-Nichols tuning, which is a common method for adjusting the PID parameters (Kp, Ti, Td) based on open-loop step response testing of the plant. Ziegler-Nichols tuning values are given for proportional, PI, and PID controllers to minimize error. An example problem demonstrates identifying plant parameters from step response data and applying Ziegler-Nichols tuning to design proportional, PI, and PID controllers.

![• Using these approximations, we can write:

𝑢 𝑛𝑇 = 𝐾𝑝[𝑒 𝑛𝑇 +

1

𝑇𝑖

𝑘=1

𝑛

𝑇𝑒 𝑘𝑇 + 𝑇𝑑

𝑒 𝑛𝑇 −𝑒(𝑛𝑇−𝑇)

𝑇

],

𝑢 𝑛𝑇 − 𝑇 = 𝐾𝑝[𝑒 𝑛𝑇 − 𝑇 +

1

𝑇𝑖

𝑘=1

𝑛−1

𝑇𝑒 𝑘𝑇 + 𝑇𝑑

𝑒 𝑛𝑇−𝑇 −𝑒(𝑛𝑇−2𝑇)

𝑇

].

• Subtracting these two equations, we obtain:

𝑢𝑛 = 𝑢𝑛−1 + 𝐾𝑝 𝑒𝑛 − 𝑒𝑛−1 +

𝐾𝑝𝑇

𝑇𝑖

𝑒𝑛 +

𝐾𝑝𝑇𝑑

𝑇

[𝑒𝑛 − 2𝑒𝑛−1 + 𝑒𝑛−2]

where 𝑢𝑛: = 𝑢(𝑛𝑇) and 𝑢𝑛−1: = 𝑢 𝑛𝑇 − 𝑇 .

• The PID is now in a suitable form which can be implemented on a digital

computer. Here the current control action uses the previous control value

as a reference.

7](https://image.slidesharecdn.com/1578385-221105091910-1dfc2958/75/1578385-ppt-7-2048.jpg)