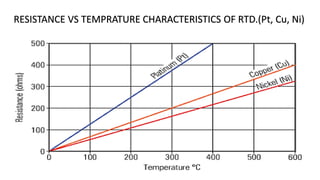

Resistance temperature detectors (RTDs) measure temperature by correlating the resistance of a sensor element like platinum, nickel, or copper to temperature. Most RTD elements consist of fine wire coiled around a core for protection. Platinum RTDs offer high accuracy from -200 to 850°C. RTDs are used in applications like refrigeration, food processing, and petrochemical processing due to their high accuracy, stability, and ability to measure narrow temperature ranges.

![If we now consider a four-wire configuration with a 1mA precision current source,[9] we obtain the following relationship between temperature and

measured voltage

TEMPRATURE AND RESISTANCE RELATIONSHIP

Here , R(t) is the resistance at temperature T,R(o) is the resistance at 0 °C, and the constants (for an alpha=0.00385 platinum

RTD) are

Since the B and C coefficients are relatively small, the resistance changes almost linearly with the temperature.

For positive temperature, if we resolve the quadratic equation we obtain the following relationship between temperature and

resistance:

The relation between temperature and resistance is given by the Callendar-Van Dusen- equation.](https://image.slidesharecdn.com/rtd-160603191810/85/Resistance-Temperature-Detector-By-Mitesh-Kumar-8-320.jpg)