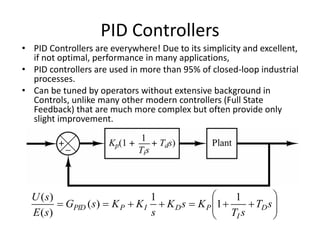

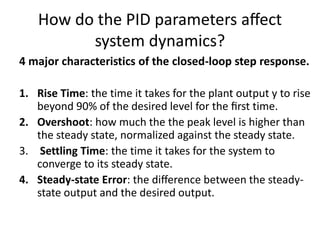

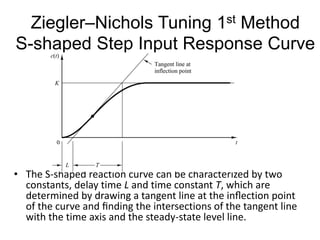

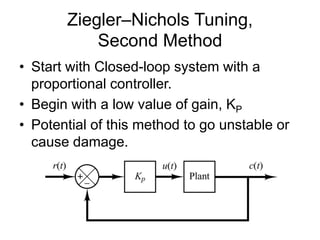

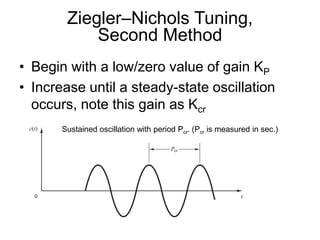

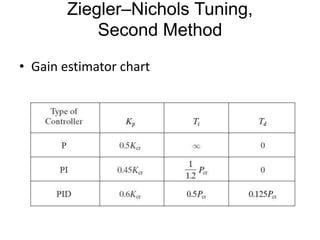

PID controllers are commonly used to control industrial processes due to their simplicity. Tuning PID controllers on-site is often necessary due to process variations. The Ziegler-Nichols tuning method provides initial estimated PID parameters based on the process response to a step input or by increasing controller gain until sustained oscillations occur. The method yields parameters that provide acceptable overshoot and settling time for initial tuning, which can then be fine-tuned based on the effects of each parameter.