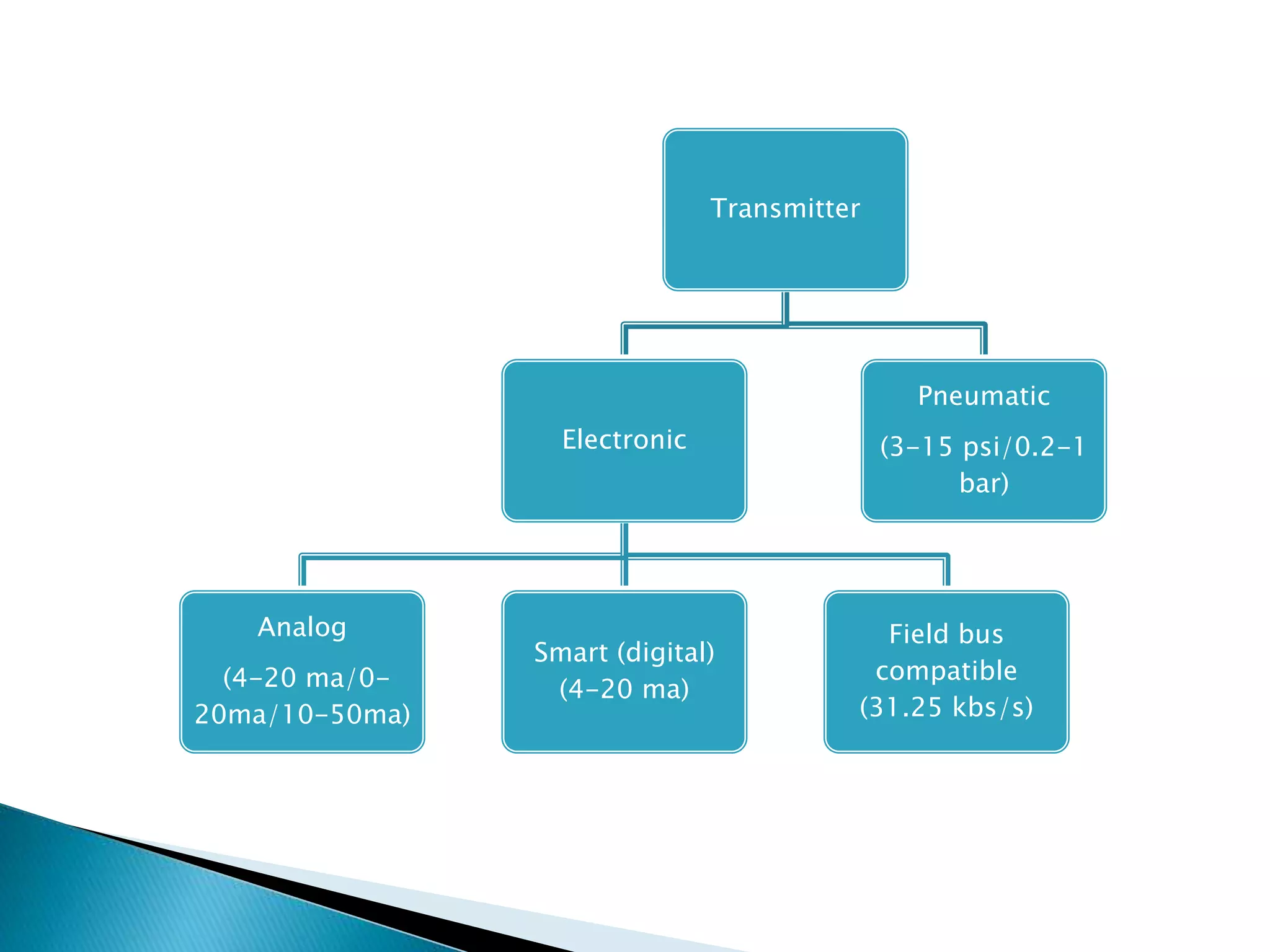

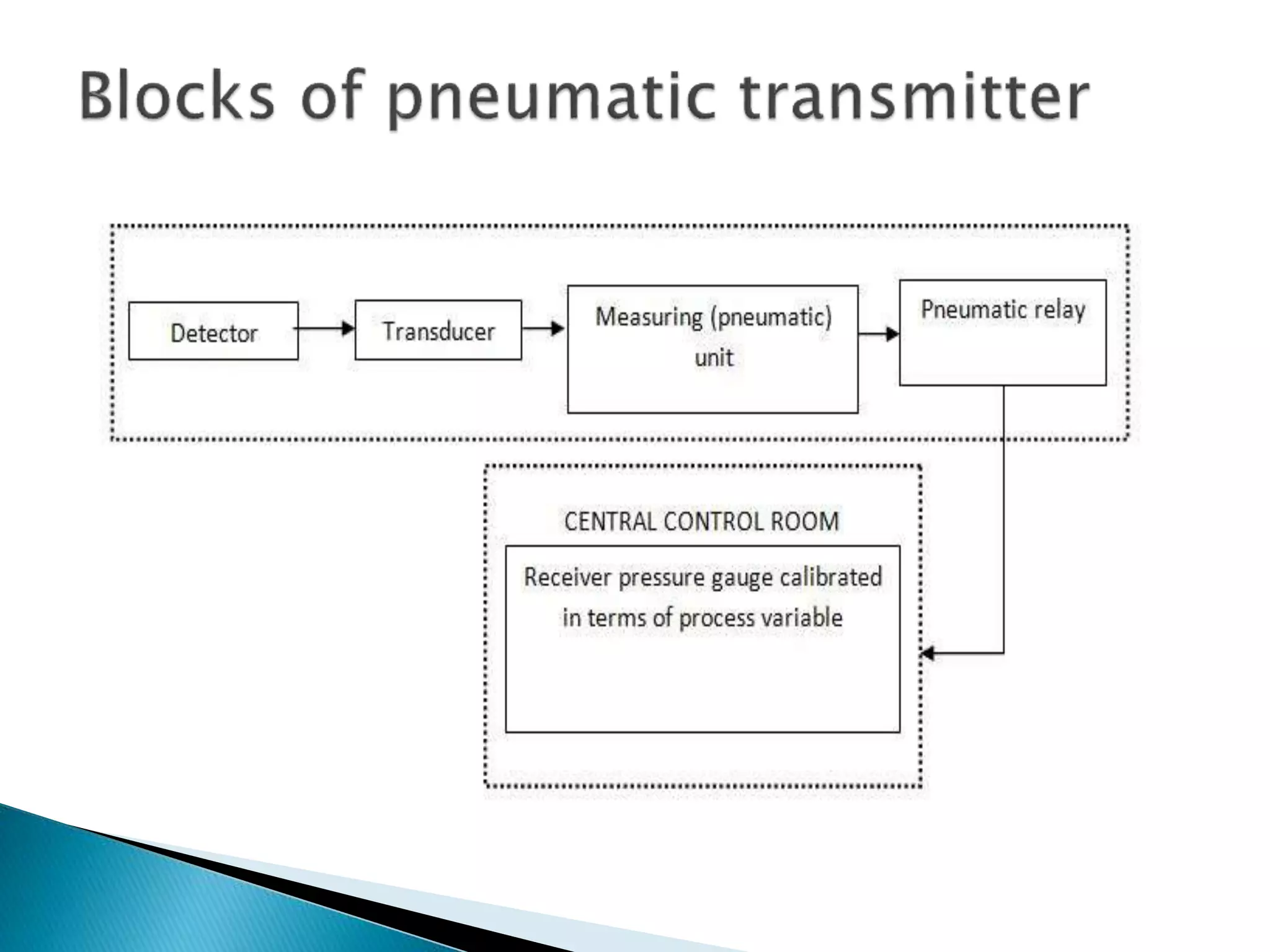

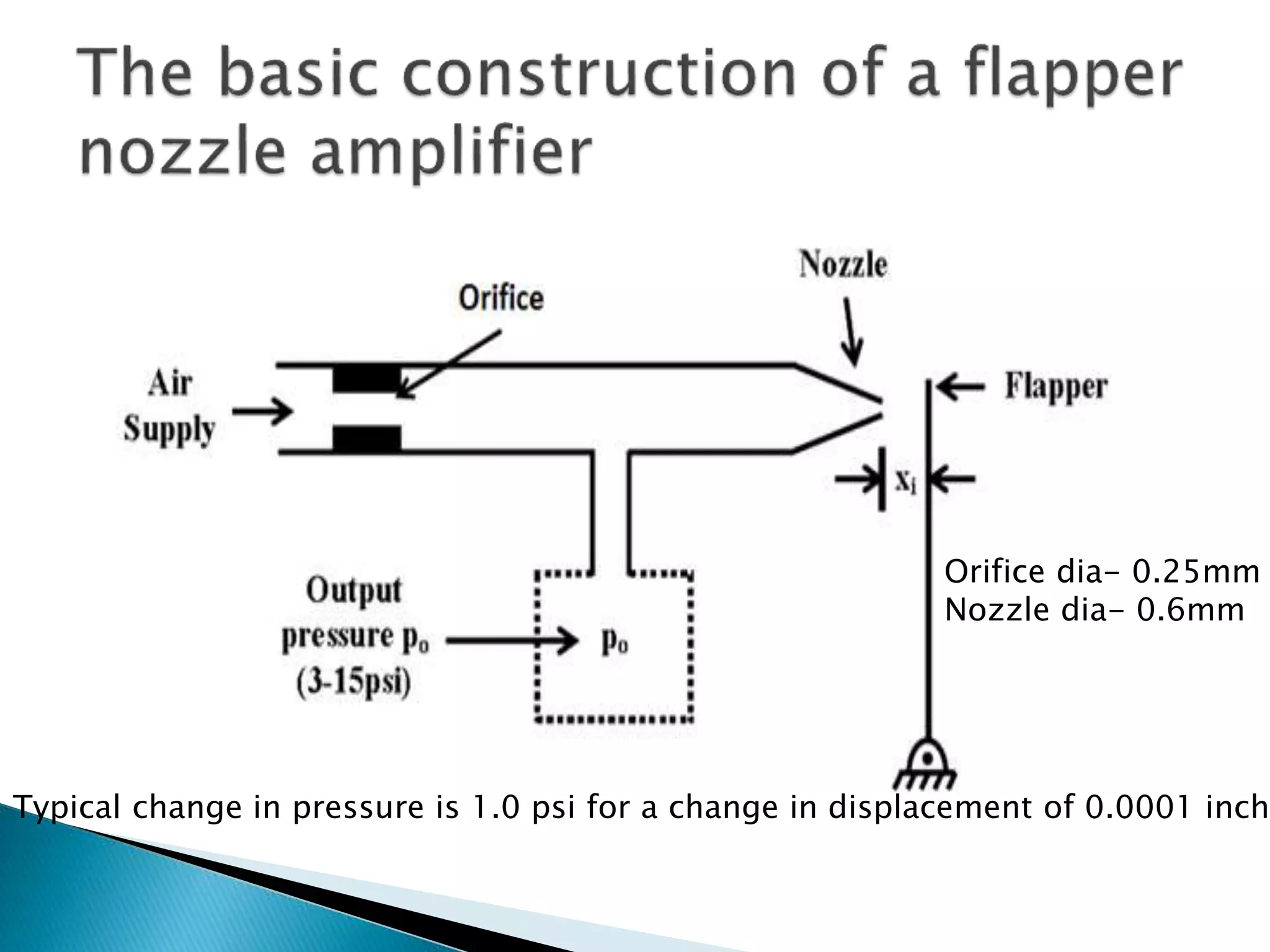

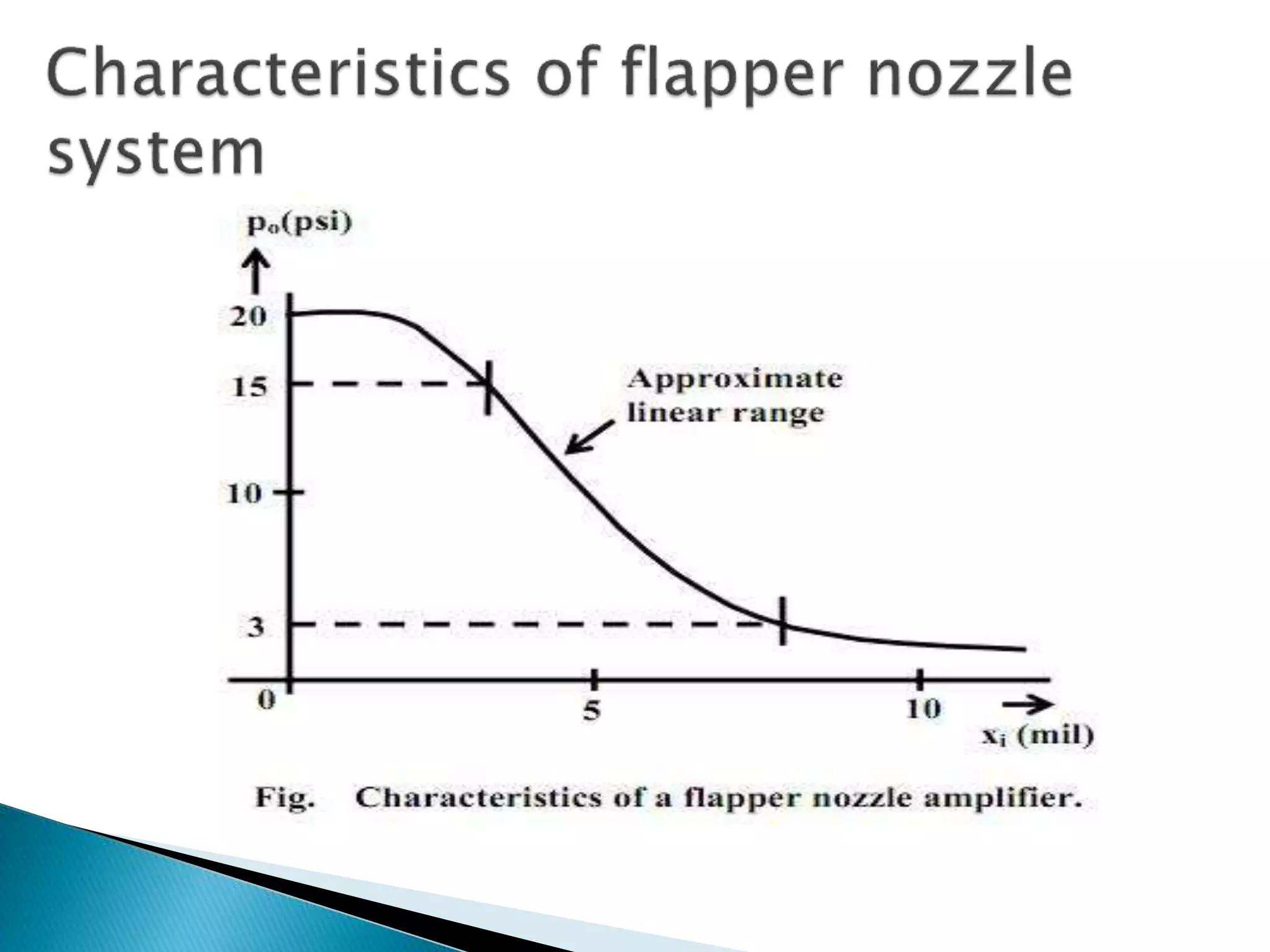

The document summarizes transmitters used in process industries. A transmitter is a transducer that converts a sensor's output into a standardized transmission signal. Common transmitter types include electronic, smart, fieldbus, and pneumatic. Pneumatic transmitters translate a measured value into an air pressure signal that is transmitted to devices for indication, recording, alarm, and control. They are safe for hazardous environments but slow. A pneumatic control system uses variable air pressure signals transmitted through pipes. A flapper nozzle amplifier converts very small displacement signals into air pressure variations used by pneumatic transmitters.