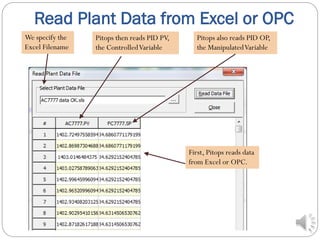

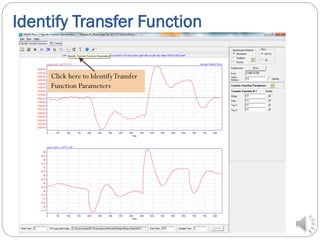

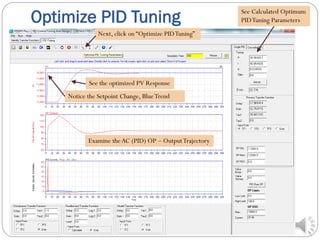

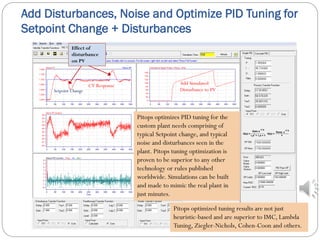

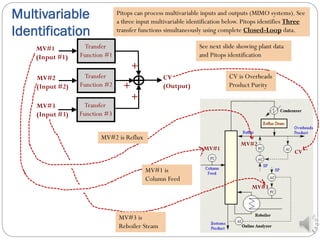

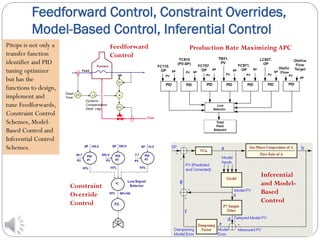

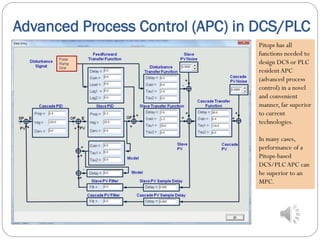

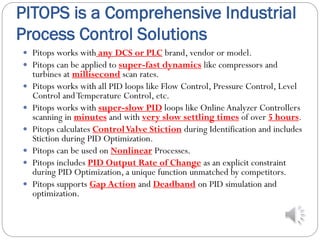

Pitops is a revolutionary process control software designed for use in industries and educational institutions, capable of identifying transfer functions and optimizing PID tuning parameters efficiently. It boasts unique features such as multivariable transfer function identification using closed-loop data and superior PID tuning optimization that can be executed in just minutes. This software is versatile, supporting various control systems and offering advanced process control functionalities, positioning it as a superior alternative to traditional control technologies.