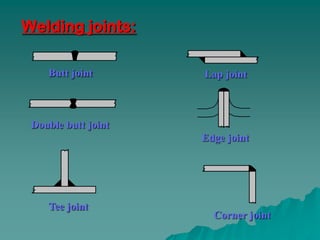

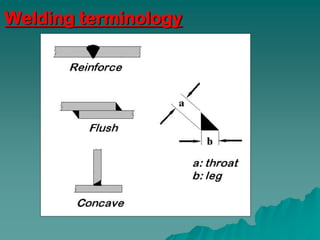

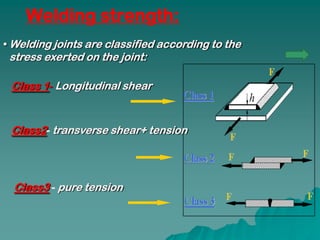

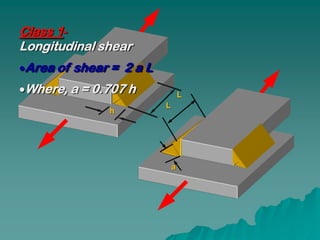

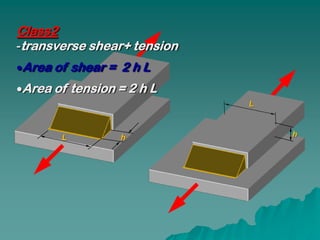

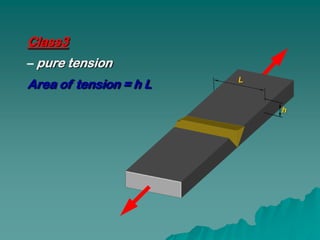

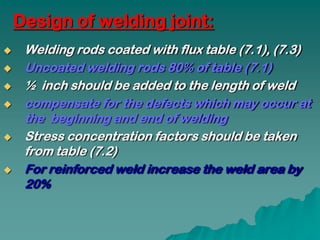

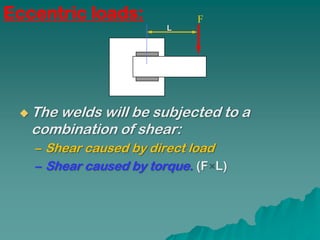

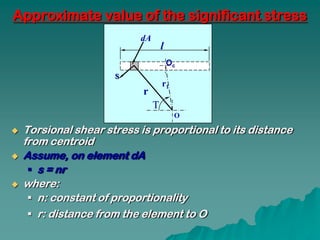

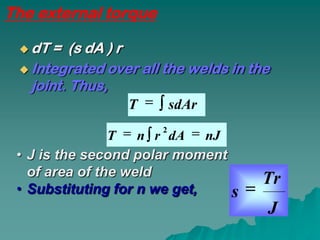

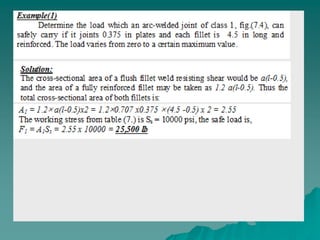

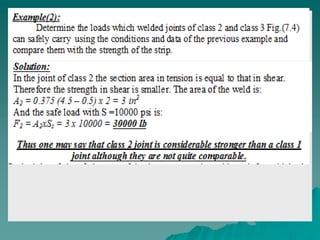

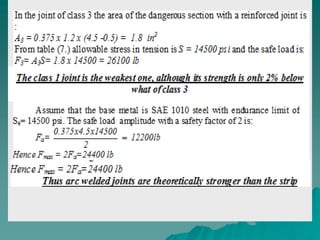

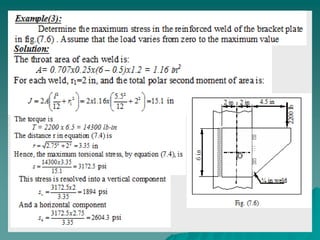

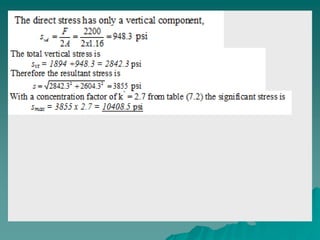

This document discusses mechanical joints and welding. It provides information on different types of mechanical joints like screws and rivets. It then discusses various welding processes like oxy-fuel gas welding, shield metal arc welding, and gas tungsten arc welding. Different welding joints are also illustrated like butt joints, lap joints, and tee joints. The document concludes with discussing welding terminology, classification of welding joints based on stress, and design considerations for welding joints.