This document discusses bolted connections and their design. It covers the following key points:

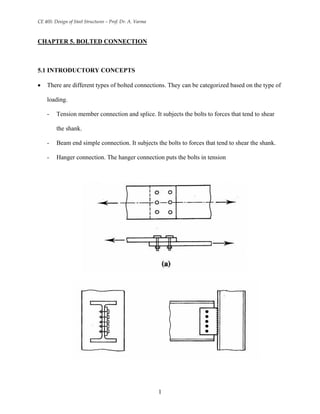

- There are different types of bolted connections depending on the loading, including tension, shear, and hanger connections. Bolts can fail due to shear or tension.

- Failure modes of bolted connections include shear failure of bolts, failure of connected members, edge tearing of plates, and excessive bearing deformation at bolt holes.

- The AISC specification provides provisions for calculating the shear strength of bolts and bearing strength of connected plates, including minimum bolt spacings and edge distances.

- Design tables are provided for determining the shear strength of individual and multiple bolts, and the bearing strength of plates