welded joints

•Download as PPTX, PDF•

3 likes•1,485 views

This document discusses welded joints and provides information on various welding processes and techniques. It describes the basic types of welding including pressure welding, fusion welding, arc welding, gas welding and resistance welding. The document also outlines standard welding symbols, common weld defects, nondestructive and destructive testing methods, and factors that influence weldability. Advantages of welded joints include strength, weight savings, and ease of alterations compared to riveted joints, though welded structures can be prone to distortion without provisions for thermal expansion/contraction.

Report

Share

Report

Share

Recommended

Introduction to Materials Testing

Subject Name: Testing of Materials (TOM)

Subject code: OML751

Unit I: Introduction to Materials Testing

B.E. Mechanical Engineering

Final year, VII Semester.

Open Elective Subject

[As per Anna university syllabus; R-2017]

Recommended

Introduction to Materials Testing

Subject Name: Testing of Materials (TOM)

Subject code: OML751

Unit I: Introduction to Materials Testing

B.E. Mechanical Engineering

Final year, VII Semester.

Open Elective Subject

[As per Anna university syllabus; R-2017]

Welding

this ppt pdf beneficial for 1st year engineering student who studying workshop technology. in this pdf types of joining, gas welding, arc welding, spot welding, tig welding, mig welding, soldering brazing and different welding defect has been discussed.

Gass tungsten Arc Welding (GTAW)/ Tungsten Inert Gas Welding (TIG)

Metallurgy and Materials Engineering Department, University of Punjab Lahore

Engineering Materials

Engineering Material, Material Classification, characteristics of materials like metal, ceramics, organic, composites and semiconductors, Engineering requirements of materials, Properties of Engineering materials, factors affecting mechanical properties, Factors affecting the selection of materials for engineering purposes, Destructive and non-destructive testing, Tensile test, stress-strain diagram, spark test, macro etching, chemical analysis, Izod Impact testing, Charpy Impact testing, Fracture, Ductile Fracture, Brittle fracture, Ductile to brittle transition, creep failure, fatigue failure, radiography testing, dye penetration testing, magnetic particle testing, ultrasonic testing,

Simple welded connection using Fillet weld

welded conection using fillet weld , fillet weilding ,description of fillet weld,, types of fillet weld, size of fillet weld, effective length of fillet weld, design of fillet weilding, design of steel structure, steel weilding, Theoretical throat of fillet weld, root of weld, face of weld, cross section of fillet weld,

Extrusion, DIrect and indirect Extrusoin Hot and Cold extrusion, Application ...

Metal forming Process

Wire rope design

It includes types of wire rope , selection procedure and hoe to find out stresses in wire rope .

Uint 1 locating and clamping devices

Design of jigs and fixtures -consist of locating and clamping principles

Clamping and Clamping Devices

What does clamping mean in context of jigs and fixtures?

Principles of Clamping

Different types of Clamping Devices, their advantaged and disadvantages

Failure analysis

The objective of this course is to provide a basic overview of failure analysis. It will include discussion of failure mechanisms, analytical techniques and case histories

• To provide you with a clear understanding of terms used so that you can ask the right questions and interpret common observations with ease

Types of failures

Failure modes

How to conduct failure analysis

Analyze data

Failure mechanism

Prevention of Failures

Failures examples

Diffusion welding by Limon Saha

A solid-state welding process that produces coalescence of the faying surfaces by the application of pressure at elevated temperature.

Design & Construction Errors- How it Affects Repair and Rehabilitation of Str...

The ultimate guide to design and construction errors and how it affects the repair and rehabilitation of structures. This data has been compiled after visiting several websites and reading books. It is mainly for the purpose of civil engineering students for the subject "Building Maintenance and Repairs".

More Related Content

What's hot

Welding

this ppt pdf beneficial for 1st year engineering student who studying workshop technology. in this pdf types of joining, gas welding, arc welding, spot welding, tig welding, mig welding, soldering brazing and different welding defect has been discussed.

Gass tungsten Arc Welding (GTAW)/ Tungsten Inert Gas Welding (TIG)

Metallurgy and Materials Engineering Department, University of Punjab Lahore

Engineering Materials

Engineering Material, Material Classification, characteristics of materials like metal, ceramics, organic, composites and semiconductors, Engineering requirements of materials, Properties of Engineering materials, factors affecting mechanical properties, Factors affecting the selection of materials for engineering purposes, Destructive and non-destructive testing, Tensile test, stress-strain diagram, spark test, macro etching, chemical analysis, Izod Impact testing, Charpy Impact testing, Fracture, Ductile Fracture, Brittle fracture, Ductile to brittle transition, creep failure, fatigue failure, radiography testing, dye penetration testing, magnetic particle testing, ultrasonic testing,

Simple welded connection using Fillet weld

welded conection using fillet weld , fillet weilding ,description of fillet weld,, types of fillet weld, size of fillet weld, effective length of fillet weld, design of fillet weilding, design of steel structure, steel weilding, Theoretical throat of fillet weld, root of weld, face of weld, cross section of fillet weld,

Extrusion, DIrect and indirect Extrusoin Hot and Cold extrusion, Application ...

Metal forming Process

Wire rope design

It includes types of wire rope , selection procedure and hoe to find out stresses in wire rope .

Uint 1 locating and clamping devices

Design of jigs and fixtures -consist of locating and clamping principles

Clamping and Clamping Devices

What does clamping mean in context of jigs and fixtures?

Principles of Clamping

Different types of Clamping Devices, their advantaged and disadvantages

Failure analysis

The objective of this course is to provide a basic overview of failure analysis. It will include discussion of failure mechanisms, analytical techniques and case histories

• To provide you with a clear understanding of terms used so that you can ask the right questions and interpret common observations with ease

Types of failures

Failure modes

How to conduct failure analysis

Analyze data

Failure mechanism

Prevention of Failures

Failures examples

Diffusion welding by Limon Saha

A solid-state welding process that produces coalescence of the faying surfaces by the application of pressure at elevated temperature.

What's hot (20)

Gass tungsten Arc Welding (GTAW)/ Tungsten Inert Gas Welding (TIG)

Gass tungsten Arc Welding (GTAW)/ Tungsten Inert Gas Welding (TIG)

Extrusion, DIrect and indirect Extrusoin Hot and Cold extrusion, Application ...

Extrusion, DIrect and indirect Extrusoin Hot and Cold extrusion, Application ...

Viewers also liked

Design & Construction Errors- How it Affects Repair and Rehabilitation of Str...

The ultimate guide to design and construction errors and how it affects the repair and rehabilitation of structures. This data has been compiled after visiting several websites and reading books. It is mainly for the purpose of civil engineering students for the subject "Building Maintenance and Repairs".

Construction errors and their case studies

Case studies of building construction which can improve errors in construction and their long durability of structure

Earthquake Resistant Building Construction

This File comprises of a general information and guidelines for construction of Earthquake Resistant buildings, Its a basic study of the same and may help students and learners for overall information of this technology.

Earthquake resistant construction

Some Baisc guidelines for Earthquake Resistant construction and facts & figures

Stone as a building material.

Stone as a building material.Director-Navnirman Bahu-Uddeshiya Mahila Sanstha,Suvarna Lele Architects.

STONE -As A Building Material.

Stones have been considered as one of the popular building material from the olden days due to their availability in abundance from the natural rocks. Building stones should possess enough strength and durability.

The stones which are suitable for the construction of the structures such as retaining walls, abutments, dams, barrages, roads etc are known as building stones. Viewers also liked (19)

Design & Construction Errors- How it Affects Repair and Rehabilitation of Str...

Design & Construction Errors- How it Affects Repair and Rehabilitation of Str...

Welded joints (machine design & industrial drafting )

Welded joints (machine design & industrial drafting )

Distress of concrete structures & their repair techniques

Distress of concrete structures & their repair techniques

Similar to welded joints

Experimental Investigation of Tensile Strength and Deflection Characteristics...

Aluminum alloys are used in many applications in which the combination of high strength and low

weight is attractive; ship building, air frame, transportation industry etc. are some areas in which the low

weight can be significant value. Friction stir welding (FSW) is a new welding technique particularly well suited

to aluminum alloys though this technique is also used for other materials. Friction stir welding promises joints

with low porosity, fine microstructures, minimum phase transformation and low oxidation compared to

conventional welding techniques. It is capable of joining combinations of alloys not amenable to conventional

welding.Experiments for tensile and deflection tests were carried out and reported in this research paper. The

base material used for friction stir welding was AA 6351–T4 Aluminum alloy. Tensile strength and breaking

loads were increased with increase of rotational speed of the tool but it drops after attaining marginal speed.

Deflections of friction stir welded specimens and base materials were compared and they exhibited almost

similar trends at different load conditions and deflections of all the specimens were increased with increment of

load

Welcome to International Journal of Engineering Research and Development (IJERD)

http://www.ijerd.com

Wbut or MAKAUT welding notes

This notes will be sufficient for the welding portion of primary manufacturing processes, ME 403 Mechanical engineering.

Similar to welded joints (20)

Advanced Manufacturing Processes PDF Full book by badebhau

Advanced Manufacturing Processes PDF Full book by badebhau

Effect of tool offset and tilt angle on weld strength of butt joint friction ...

Effect of tool offset and tilt angle on weld strength of butt joint friction ...

Experimental Investigation of Tensile Strength and Deflection Characteristics...

Experimental Investigation of Tensile Strength and Deflection Characteristics...

Welcome to International Journal of Engineering Research and Development (IJERD)

Welcome to International Journal of Engineering Research and Development (IJERD)

Recently uploaded

Water Industry Process Automation and Control Monthly - May 2024.pdf

Water Industry Process Automation and Control Monthly - May 2024.pdfWater Industry Process Automation & Control

Welcome to WIPAC Monthly the magazine brought to you by the LinkedIn Group Water Industry Process Automation & Control.

In this month's edition, along with this month's industry news to celebrate the 13 years since the group was created we have articles including

A case study of the used of Advanced Process Control at the Wastewater Treatment works at Lleida in Spain

A look back on an article on smart wastewater networks in order to see how the industry has measured up in the interim around the adoption of Digital Transformation in the Water Industry.Final project report on grocery store management system..pdf

In today’s fast-changing business environment, it’s extremely important to be able to respond to client needs in the most effective and timely manner. If your customers wish to see your business online and have instant access to your products or services.

Online Grocery Store is an e-commerce website, which retails various grocery products. This project allows viewing various products available enables registered users to purchase desired products instantly using Paytm, UPI payment processor (Instant Pay) and also can place order by using Cash on Delivery (Pay Later) option. This project provides an easy access to Administrators and Managers to view orders placed using Pay Later and Instant Pay options.

In order to develop an e-commerce website, a number of Technologies must be studied and understood. These include multi-tiered architecture, server and client-side scripting techniques, implementation technologies, programming language (such as PHP, HTML, CSS, JavaScript) and MySQL relational databases. This is a project with the objective to develop a basic website where a consumer is provided with a shopping cart website and also to know about the technologies used to develop such a website.

This document will discuss each of the underlying technologies to create and implement an e- commerce website.

Governing Equations for Fundamental Aerodynamics_Anderson2010.pdf

Governing Equations for Fundamental Aerodynamics

在线办理(ANU毕业证书)澳洲国立大学毕业证录取通知书一模一样

学校原件一模一样【微信:741003700 】《(ANU毕业证书)澳洲国立大学毕业证》【微信:741003700 】学位证,留信认证(真实可查,永久存档)原件一模一样纸张工艺/offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微741003700

【主营项目】

一.毕业证【q微741003700】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微741003700】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

Advancements in technology unveil a myriad of electrical and electronic breakthroughs geared towards efficiently harnessing limited resources to meet human energy demands. The optimization of hybrid solar PV panels and pumped hydro energy supply systems plays a pivotal role in utilizing natural resources effectively. This initiative not only benefits humanity but also fosters environmental sustainability. The study investigated the design optimization of these hybrid systems, focusing on understanding solar radiation patterns, identifying geographical influences on solar radiation, formulating a mathematical model for system optimization, and determining the optimal configuration of PV panels and pumped hydro storage. Through a comparative analysis approach and eight weeks of data collection, the study addressed key research questions related to solar radiation patterns and optimal system design. The findings highlighted regions with heightened solar radiation levels, showcasing substantial potential for power generation and emphasizing the system's efficiency. Optimizing system design significantly boosted power generation, promoted renewable energy utilization, and enhanced energy storage capacity. The study underscored the benefits of optimizing hybrid solar PV panels and pumped hydro energy supply systems for sustainable energy usage. Optimizing the design of solar PV panels and pumped hydro energy supply systems as examined across diverse climatic conditions in a developing country, not only enhances power generation but also improves the integration of renewable energy sources and boosts energy storage capacities, particularly beneficial for less economically prosperous regions. Additionally, the study provides valuable insights for advancing energy research in economically viable areas. Recommendations included conducting site-specific assessments, utilizing advanced modeling tools, implementing regular maintenance protocols, and enhancing communication among system components.

Gen AI Study Jams _ For the GDSC Leads in India.pdf

Gen AI Study Jams _ For the GDSC Leads in India.pdf

The Benefits and Techniques of Trenchless Pipe Repair.pdf

Explore the innovative world of trenchless pipe repair with our comprehensive guide, "The Benefits and Techniques of Trenchless Pipe Repair." This document delves into the modern methods of repairing underground pipes without the need for extensive excavation, highlighting the numerous advantages and the latest techniques used in the industry.

Learn about the cost savings, reduced environmental impact, and minimal disruption associated with trenchless technology. Discover detailed explanations of popular techniques such as pipe bursting, cured-in-place pipe (CIPP) lining, and directional drilling. Understand how these methods can be applied to various types of infrastructure, from residential plumbing to large-scale municipal systems.

Ideal for homeowners, contractors, engineers, and anyone interested in modern plumbing solutions, this guide provides valuable insights into why trenchless pipe repair is becoming the preferred choice for pipe rehabilitation. Stay informed about the latest advancements and best practices in the field.

Hierarchical Digital Twin of a Naval Power System

A hierarchical digital twin of a Naval DC power system has been developed and experimentally verified. Similar to other state-of-the-art digital twins, this technology creates a digital replica of the physical system executed in real-time or faster, which can modify hardware controls. However, its advantage stems from distributing computational efforts by utilizing a hierarchical structure composed of lower-level digital twin blocks and a higher-level system digital twin. Each digital twin block is associated with a physical subsystem of the hardware and communicates with a singular system digital twin, which creates a system-level response. By extracting information from each level of the hierarchy, power system controls of the hardware were reconfigured autonomously. This hierarchical digital twin development offers several advantages over other digital twins, particularly in the field of naval power systems. The hierarchical structure allows for greater computational efficiency and scalability while the ability to autonomously reconfigure hardware controls offers increased flexibility and responsiveness. The hierarchical decomposition and models utilized were well aligned with the physical twin, as indicated by the maximum deviations between the developed digital twin hierarchy and the hardware.

一比一原版(IIT毕业证)伊利诺伊理工大学毕业证成绩单专业办理

IIT毕业证原版定制【微信:176555708】【伊利诺伊理工大学毕业证成绩单-学位证】【微信:176555708】(留信学历认证永久存档查询)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

◆◆◆◆◆ — — — — — — — — 【留学教育】留学归国服务中心 — — — — — -◆◆◆◆◆

【主营项目】

一.毕业证【微信:176555708】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【微信:176555708】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分→ 【关于价格问题(保证一手价格)

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

选择实体注册公司办理,更放心,更安全!我们的承诺:可来公司面谈,可签订合同,会陪同客户一起到教育部认证窗口递交认证材料,客户在教育部官方认证查询网站查询到认证通过结果后付款,不成功不收费!

学历顾问:微信:176555708

Recently uploaded (20)

Water Industry Process Automation and Control Monthly - May 2024.pdf

Water Industry Process Automation and Control Monthly - May 2024.pdf

Final project report on grocery store management system..pdf

Final project report on grocery store management system..pdf

Governing Equations for Fundamental Aerodynamics_Anderson2010.pdf

Governing Equations for Fundamental Aerodynamics_Anderson2010.pdf

Pile Foundation by Venkatesh Taduvai (Sub Geotechnical Engineering II)-conver...

Pile Foundation by Venkatesh Taduvai (Sub Geotechnical Engineering II)-conver...

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

Gen AI Study Jams _ For the GDSC Leads in India.pdf

Gen AI Study Jams _ For the GDSC Leads in India.pdf

The Benefits and Techniques of Trenchless Pipe Repair.pdf

The Benefits and Techniques of Trenchless Pipe Repair.pdf

welded joints

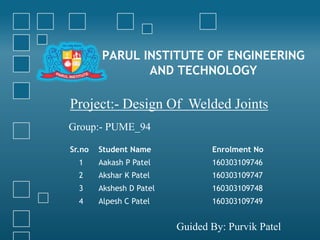

- 1. PARUL INSTITUTE OF ENGINEERING AND TECHNOLOGY Project:- Design Of Welded Joints Group:- PUME_94 Guided By: Purvik Patel Sr.no Student Name Enrolment No 1 Aakash P Patel 160303109746 2 Akshar K Patel 160303109747 3 Akshesh D Patel 160303109748 4 Alpesh C Patel 160303109749

- 2. INTRODUCTION The process of permanently joining two or more metal parts by the fusion of edges of the metals with or without applying pressure and a filler material is called welding Types of Welding (1)Pressure or Plastic welding The piece of metal to be joined are heated to a plastic state and forced together by external pressure (Ex) Resistance welding (2)Fusion welding The material at the joint is heated to a molten state and allowed to solidify (Ex) Gas welding, Arc welding

- 3. Classification of welding processes (i). Arc welding • Carbon arc • Metal arc • Metal inert gas • Tungsten inert gas • Plasma arc • Submerged arc • Electro-slag (ii). Gas Welding • Oxy-acetylene • Air-acetylene • Oxy-hydrogen (iii). Resistance Welding • Butt • Spot • Seam • Projection • Percussion (iv)Thermit Welding (v)Solid State Welding • Friction • Ultrasonic • Diffusion • Explosive

- 4. (vi)Newer Welding • Electron-beam • Laser (vii)Related Process • Oxy-acetylene cutting • Arc cutting • Hard facing Brazing • Soldering

- 5. Standard Location of Elements of a Welding Symbol According to Indian Standards, IS: 813 – 1961 (Reaffirmed 1991), the elements of a welding symbol shall have standard locations with respect to each other.

- 6. Basic Weld Symbol

- 9. Supplementary weld symbols

- 10. Workpiece thickness limits per joint type Joint type Thickness Square joint Up to 1⁄4 in (6.35 mm) Single-bevel joint 3⁄16–3⁄8 in (4.76–9.53 mm) Double-bevel joint Over 3⁄8 in (9.53 mm) Single-V joint Up to 3⁄4 in (19.05 mm) Double-V joint Over 3⁄4 in (19.05 mm) Single-J joint 1⁄2–3⁄4 in (12.70–19.05 mm) Double-J joint Over 3⁄4 in (19.05 mm) Single-U joint Up to 3⁄4 in (19.05 mm) Double-U joint Over 3⁄4 in (19.05 mm) Flange (edge of corner) Sheet metal less than 12 gauge (0.1046 in or 2.657 mm) Flare groove All thickness

- 11. Weldability Factors: Base Metal 1. Some metals melt too easily; e.g., aluminum 2. Metals with high thermal conductivity transfer heat away from weld, which causes problems; e.g., copper 3. High thermal expansion and contraction in metal causes distortion problems 4. Dissimilar metals pose problems in welding when their physical and/or mechanical properties are substantially different

- 12. Inspection and Testing Methods: Nondestructive Evaluation (NDE) Tests 1. Ultrasonic testing - high frequency sound waves through specimen to detect cracks and inclusions 2. Radiographic testing - x-rays or gamma radiation provide photographs of internal flaws 3. Dye-penetrant and fluorescent-penetrant tests - to detect small cracks and cavities at part surface 4. Magnetic particle testing – iron filings sprinkled on surface reveal subsurface defects that distort the magnetic field

- 13. Destructive Testing - Mechanical Tests 1. Tension-shear test, 2. fillet break test, 3. tension-shear of spot weld, and 4. peel test for spot weld

- 14. Welding defects Porous welds Poor penetration Warping Undercut & Underfill Distortion Cracked welds Poor appearance Poor fusion Brittle welds Spatter Magnetic blow Weld stress

- 15. Advantages and Disadvantages of Welded Joints over Riveted Joints Advantages (1) The welded structures are usually lighter than riveted structures. This is due to the reason, that in welding, gussets or other connecting components are not used. (2) The welded joints provide maximum efficiency (may be 100%) which is not possible in case of riveted joints. (3) Alterations and additions can be easily made in the existing structures. (4) As the welded structure is smooth in appearance, therefore it looks pleasing. (5) In welded connections, the tension members are not weakened as in the case of riveted joints.

- 16. (6) A welded joint has a great strength. Often a welded joint has the strength of the parent metal itself. (7) Sometimes, the members are of such a shape (i.e. circular steel pipes) that they afford difficulty for riveting. But they can be easily welded. (8) The welding provides very rigid joints. This is in line with the modern trend of providing rigid frames. (9) It is possible to weld any part of a structure at any point. But riveting requires enough clearance. (10) The process of welding takes less time than the riveting.

- 17. Dis-Advantages (1) Since there is an uneven heating and cooling during fabrication, therefore the members may get distorted or additional stresses may develop. (2) It requires a highly skilled labour and supervision. (3) Since no provision is kept for expansion and contraction in the frame, therefore there is a possibility of cracks developing in it. (4) The inspection of welding work is more difficult than riveting work.