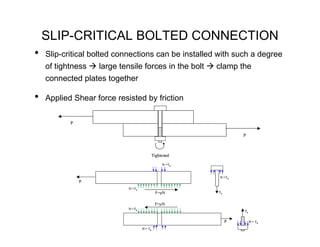

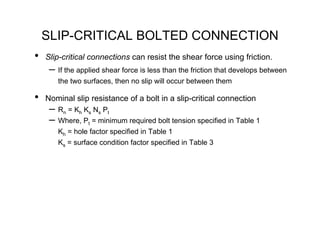

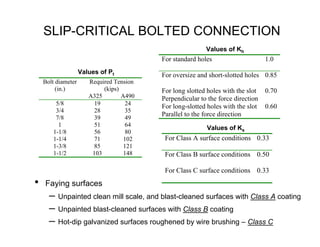

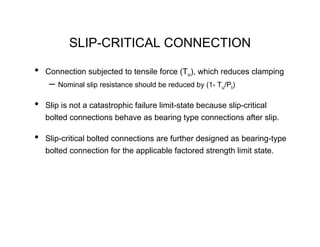

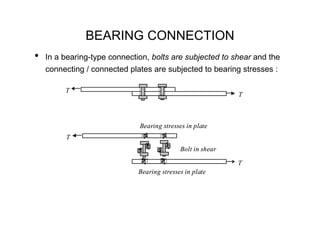

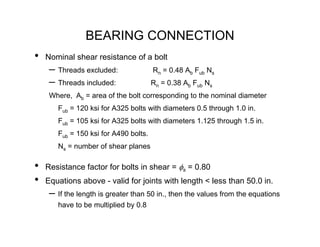

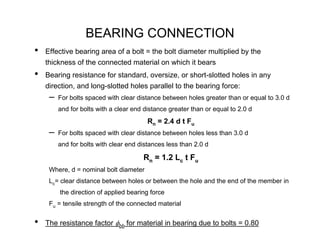

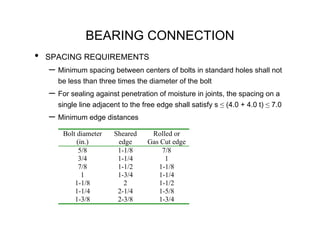

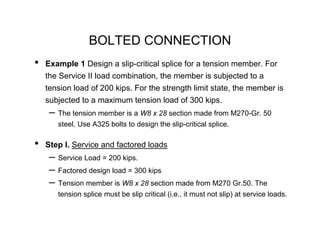

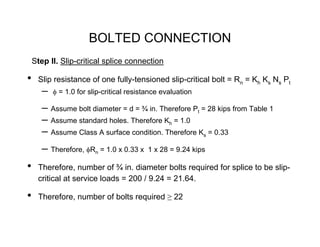

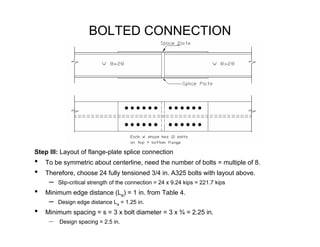

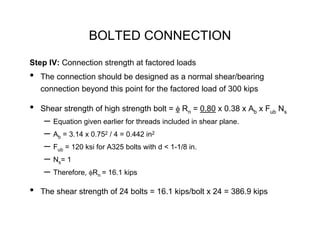

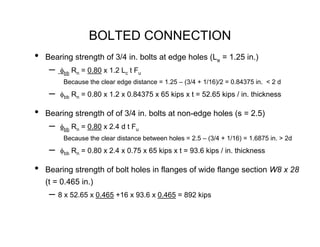

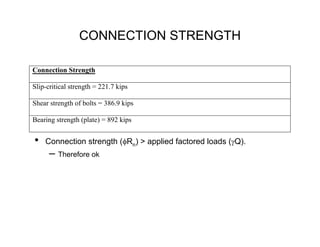

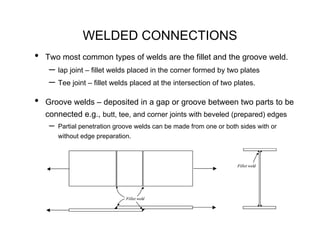

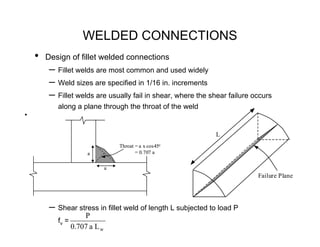

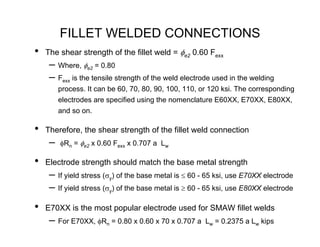

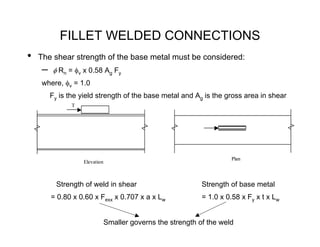

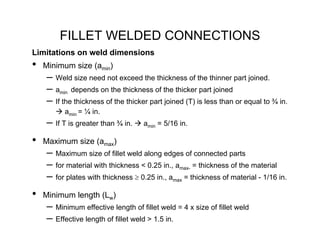

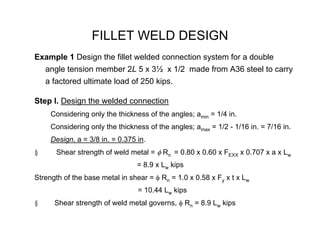

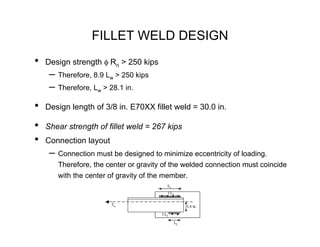

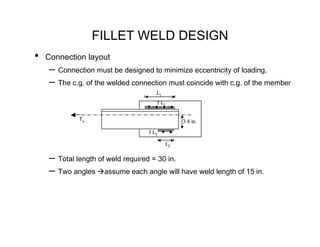

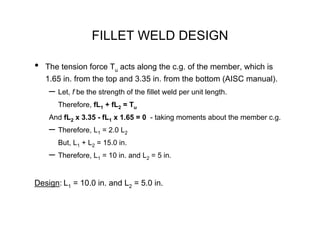

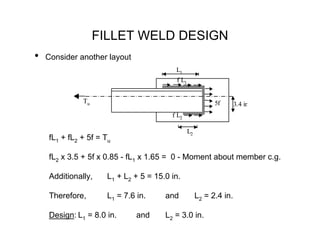

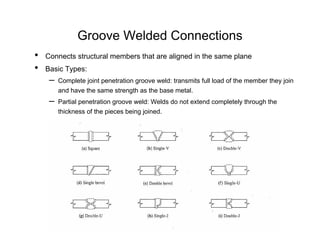

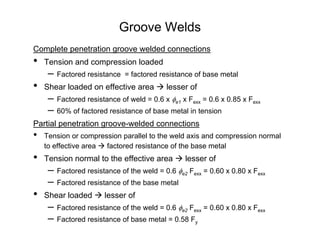

This document provides design guidelines for bolted and welded connections. It discusses designing connections for strength and serviceability limit states. Specific guidelines are provided for designing slip-critical bolted connections, bearing-type bolted connections, and fillet welded connections. Design procedures include determining the number and size of bolts or welds required based on the applied loads and capacities of the connection elements.