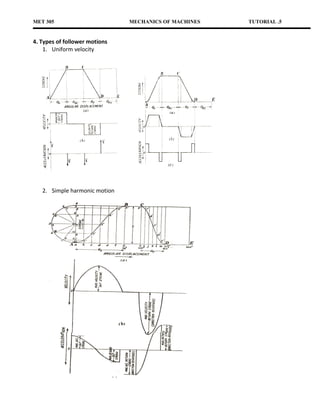

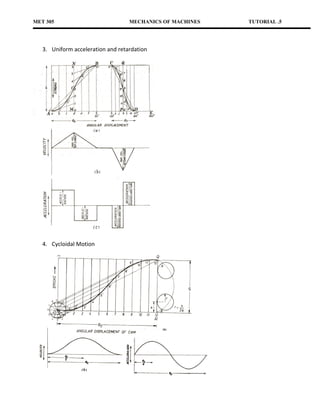

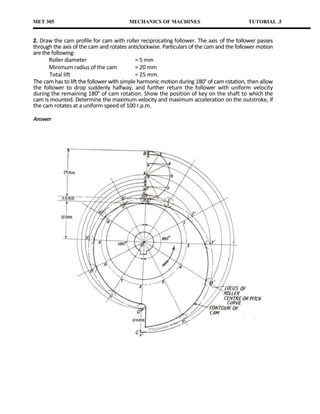

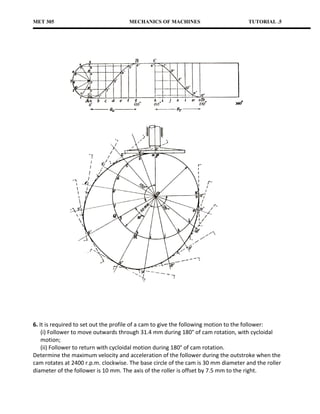

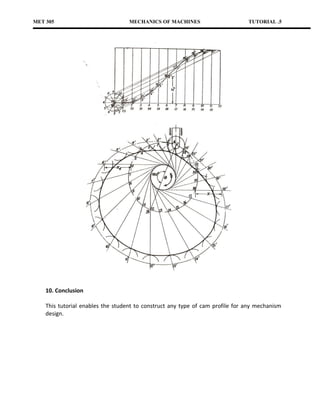

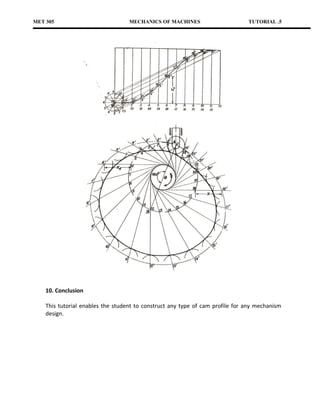

This document discusses different types of cams and cam mechanisms. It describes various types of followers based on their contacting surface, motion, and path of motion. It also defines important cam terminology used to describe cam profiles such as base circle, trace point, pressure angle, pitch point, pitch circle, and lift. The document provides examples of cam profiles that produce uniform velocity, simple harmonic, uniform acceleration/retardation, and cycloidal motions in the follower. It includes example problems of constructing cam profiles for different follower motions and specifications.