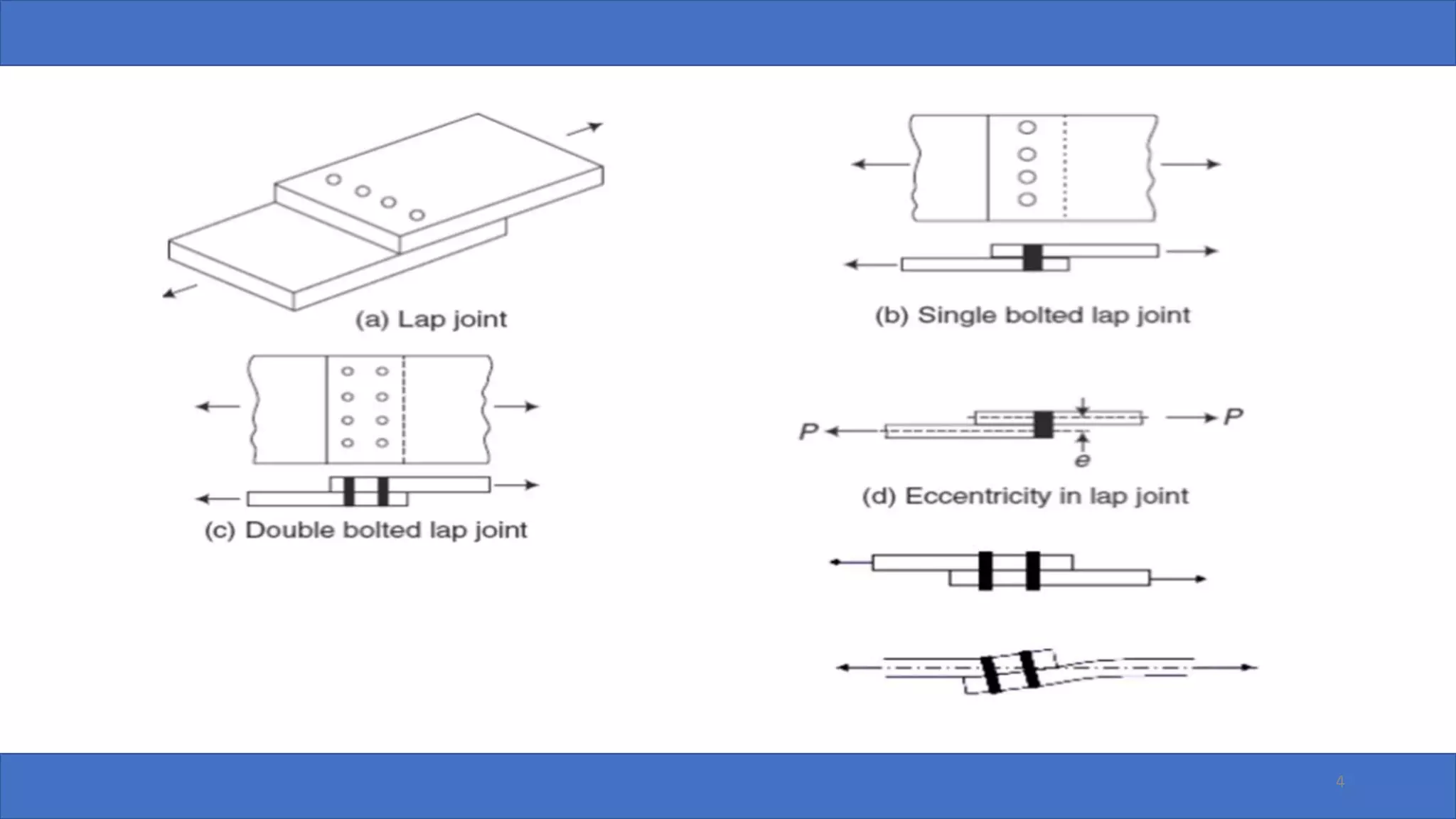

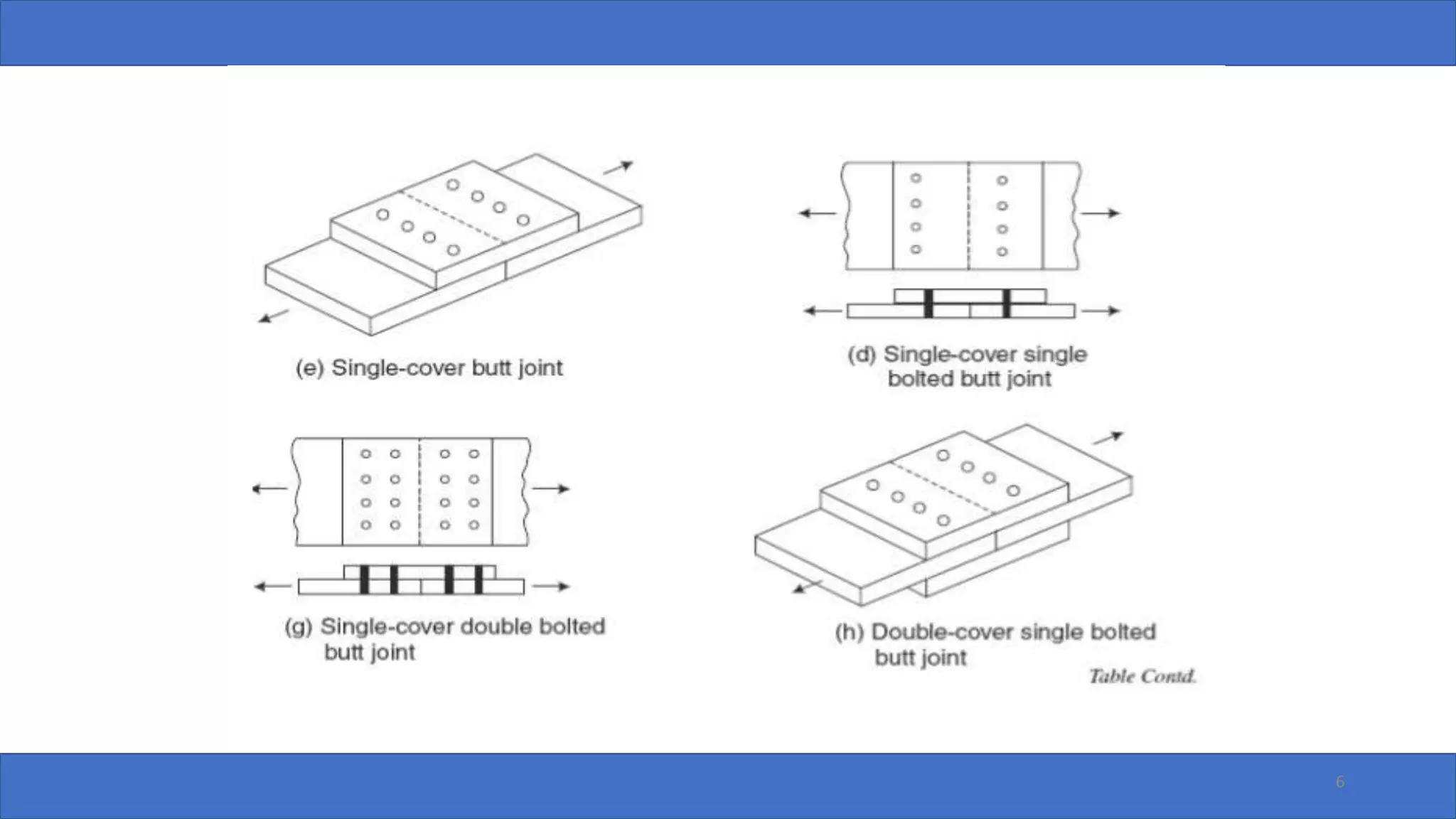

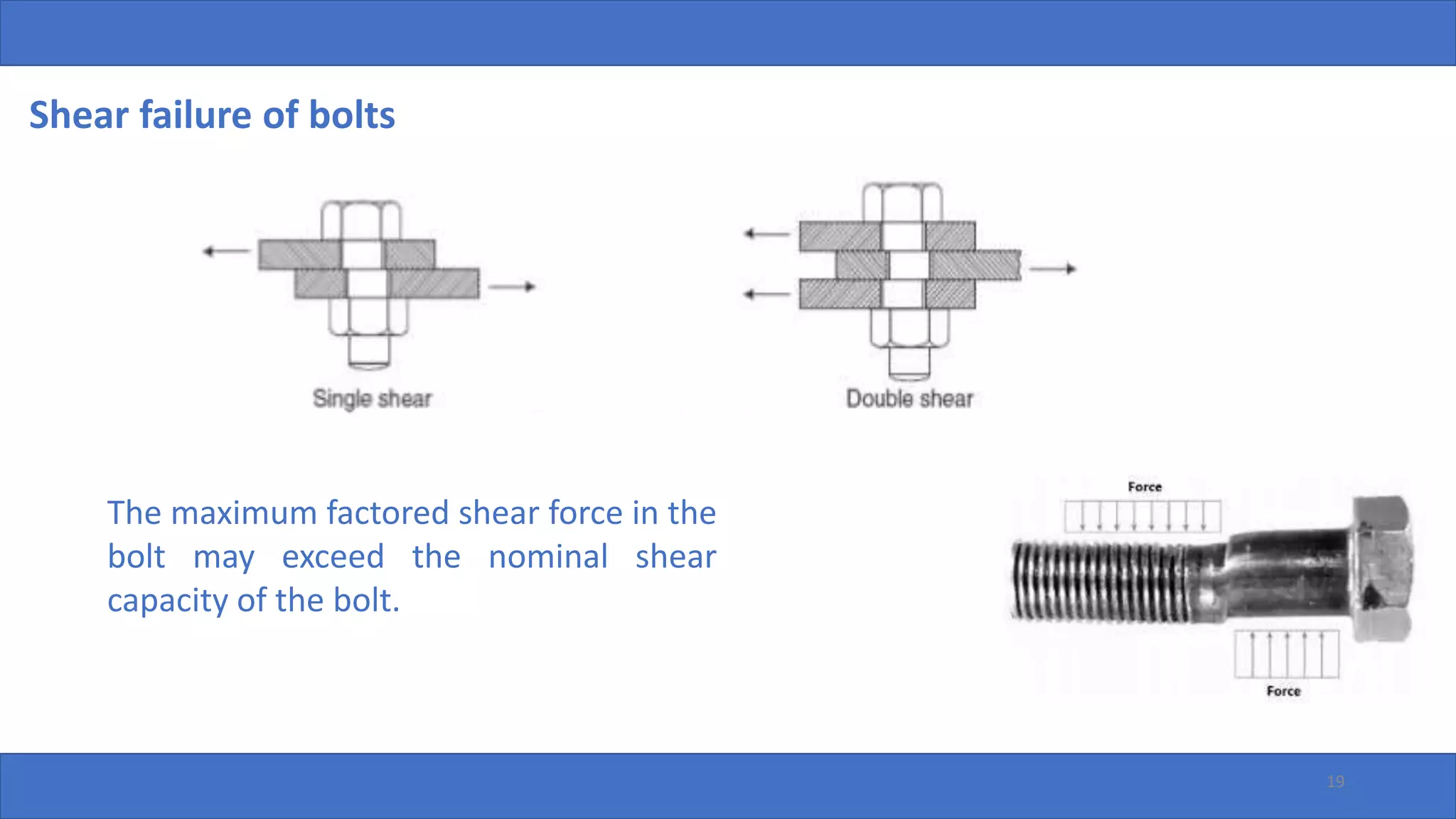

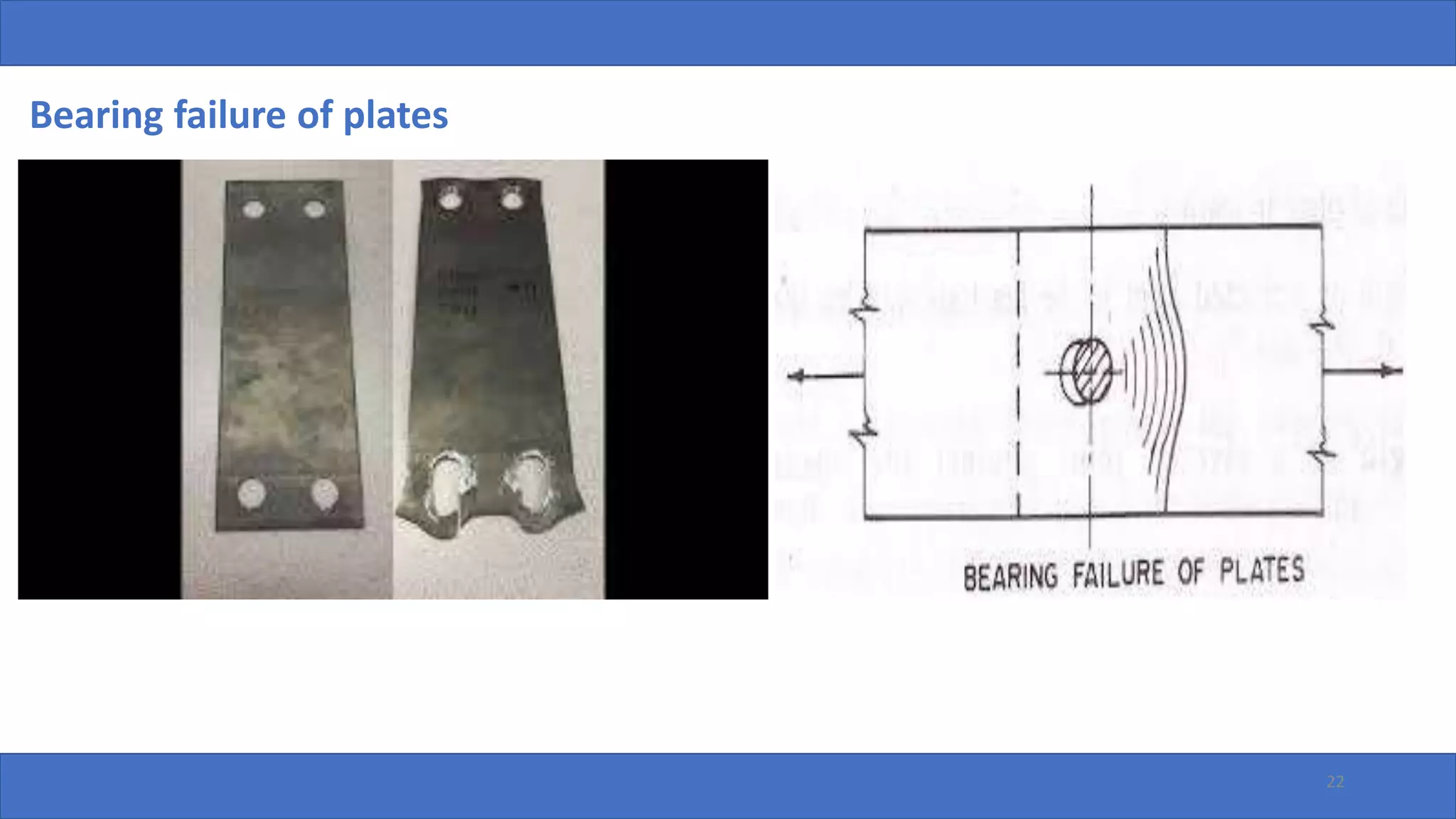

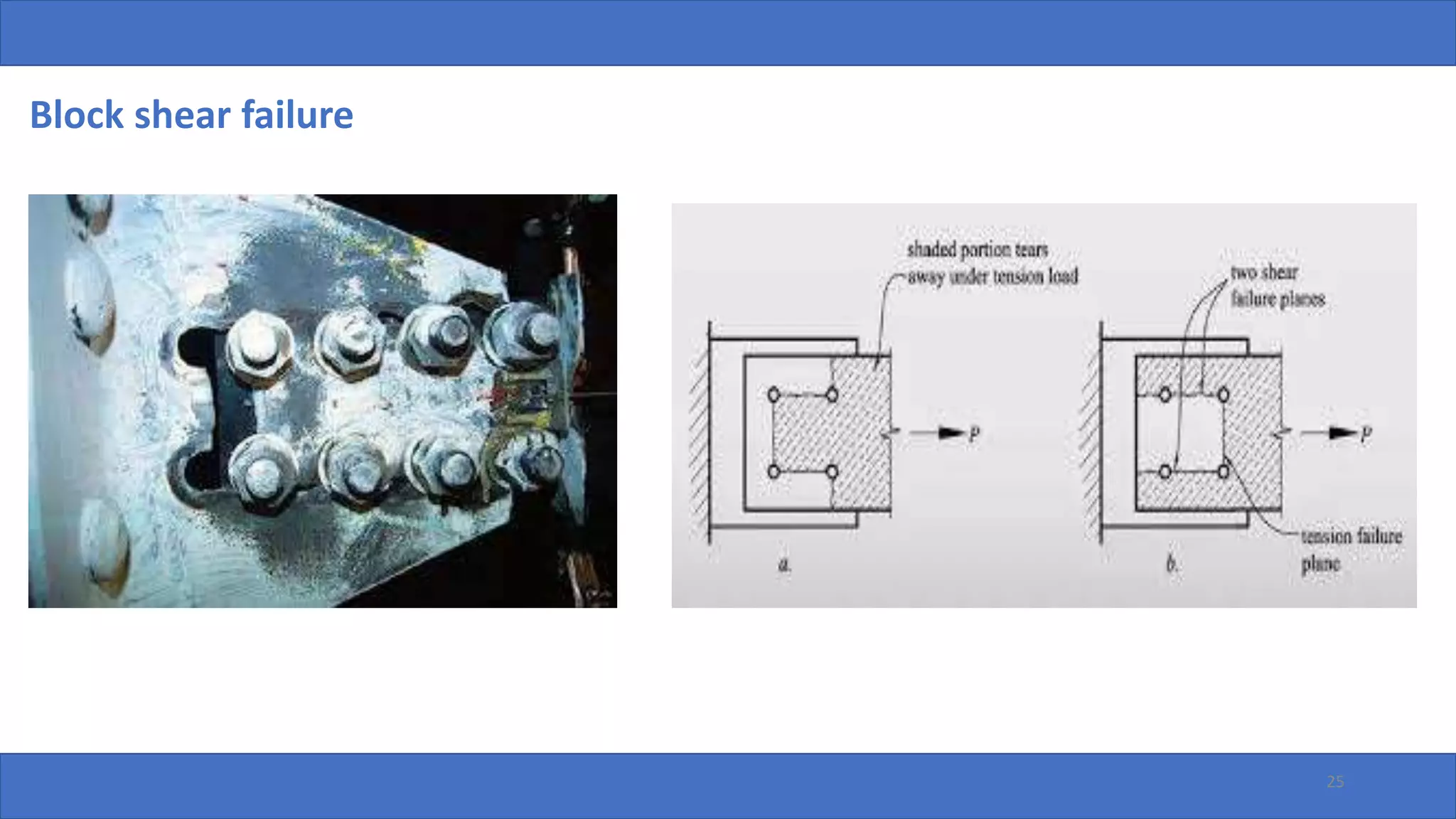

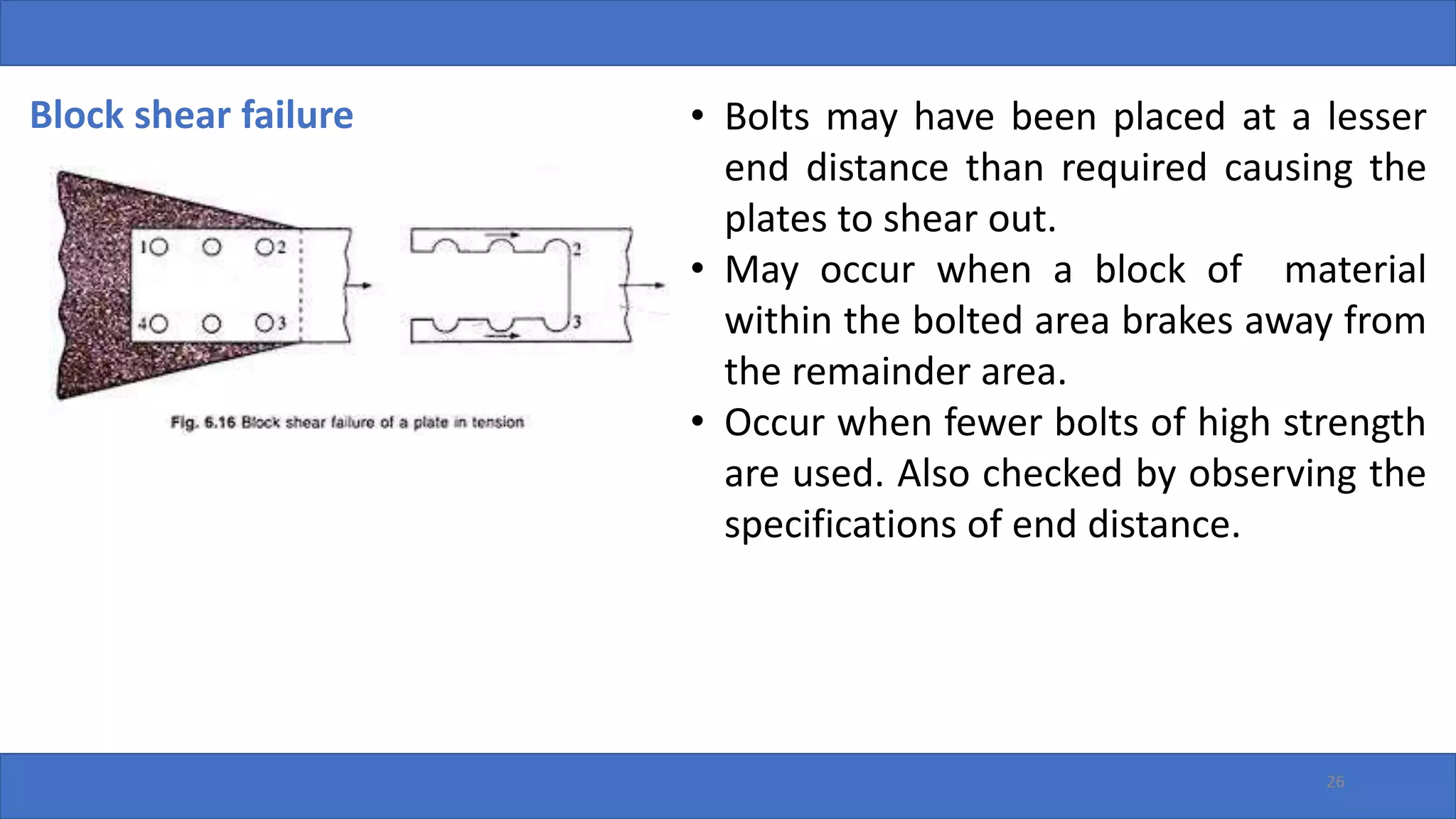

This document discusses types of bolt connections based on arrangement of bolts and plates, mode of load transmission, and nature and location of load. There are two main types of joints subjected to axial loads: lap joints and butt joints. Butt joints are preferable to lap joints because the load is split between members, eliminating eccentricity and bending. Bolt connections can fail due to shear, bearing, or tension failures of bolts or plates. The design strength of bolts is governed by their strength in shear, bearing, or tension with safety factors applied.