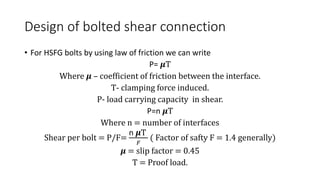

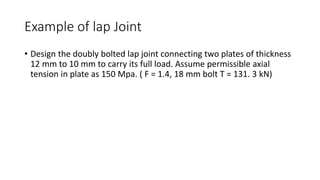

The document discusses bolted connections, describing different types of bolts according to material, strength, shear type, fit, pitch, and head shape. It outlines advantages like strength, speed of installation, and easy removal compared to rivets. Disadvantages include reduced strength in axial tension and from loosening under vibration. Types of bolted joints include lap, butt, shop, and field joints. Analysis and design of bolted connections is similar to rivets, accounting for bolt strength based on nominal diameter. Design of bolted shear connections uses laws of friction to calculate load capacity based on number of interfaces and clamping force. An example problem is given to design a doubly bolted lap joint.