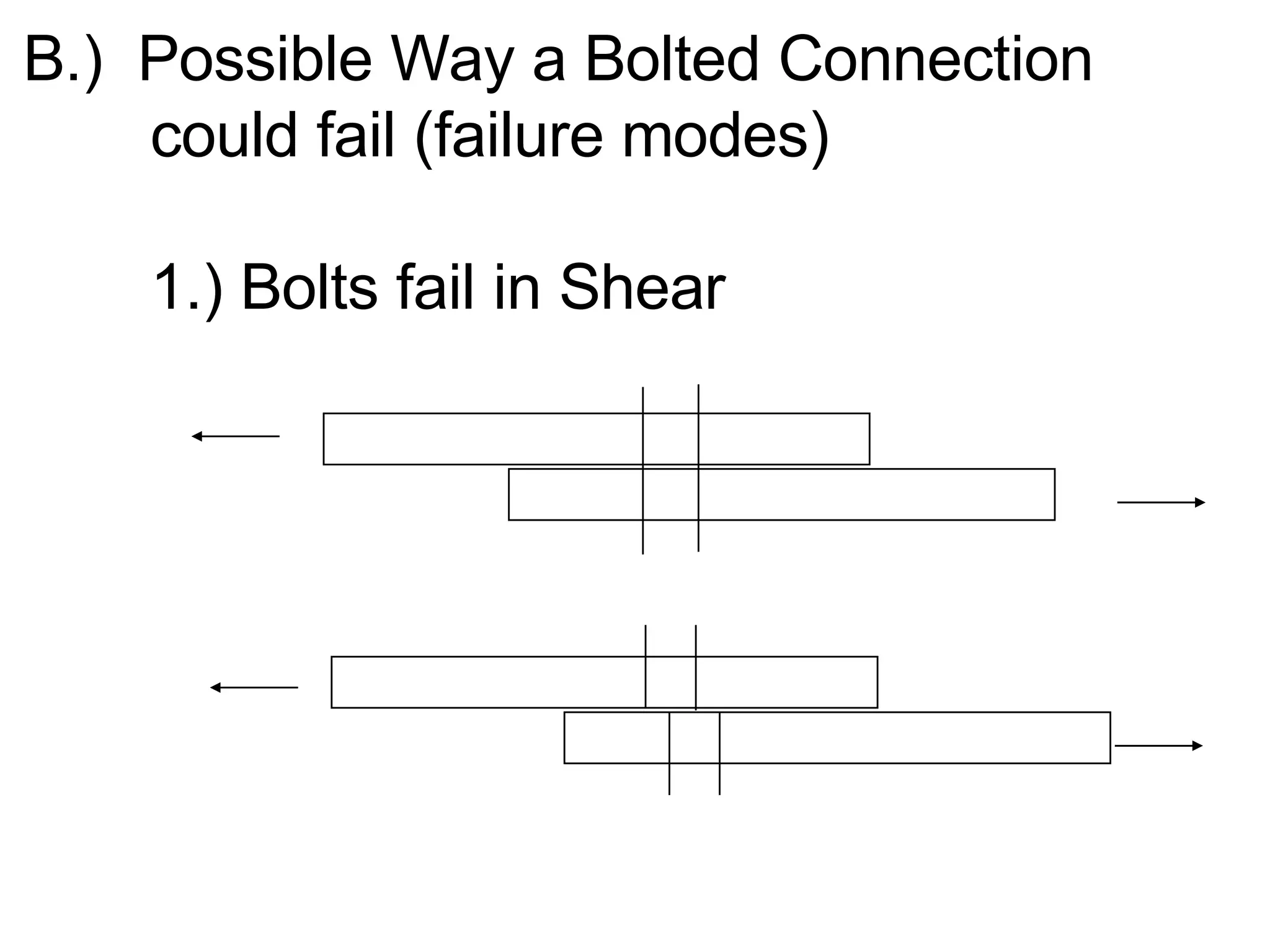

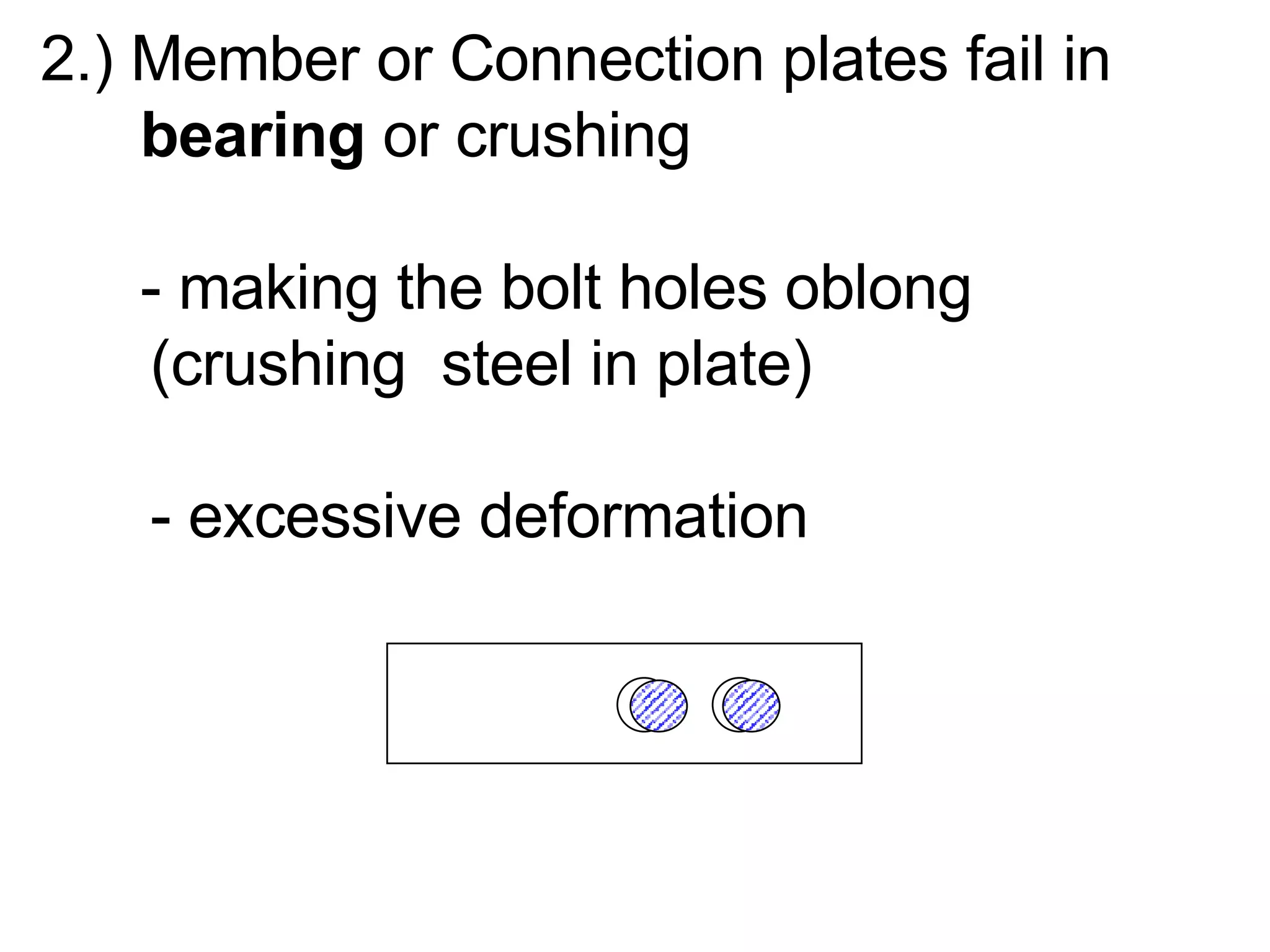

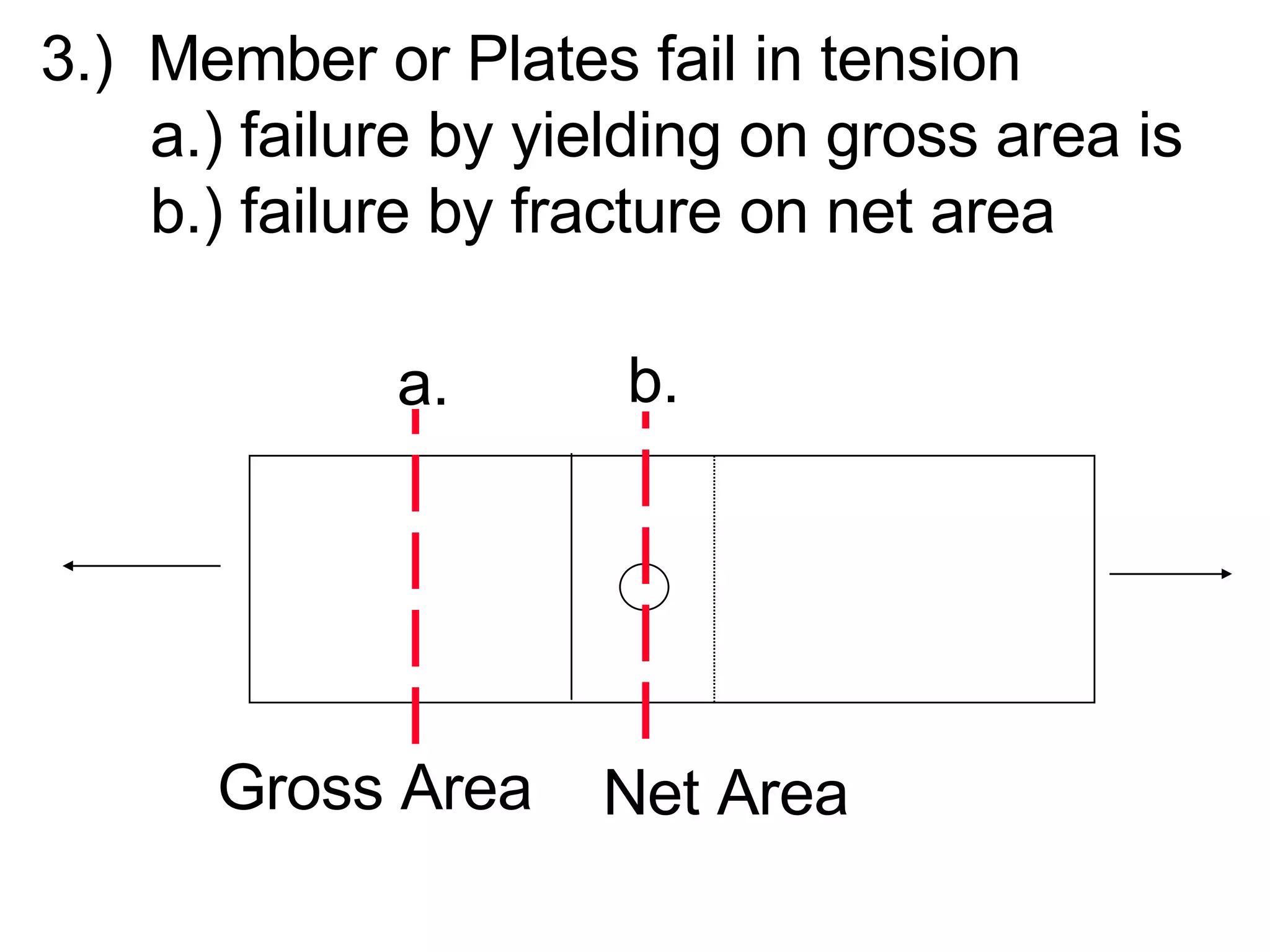

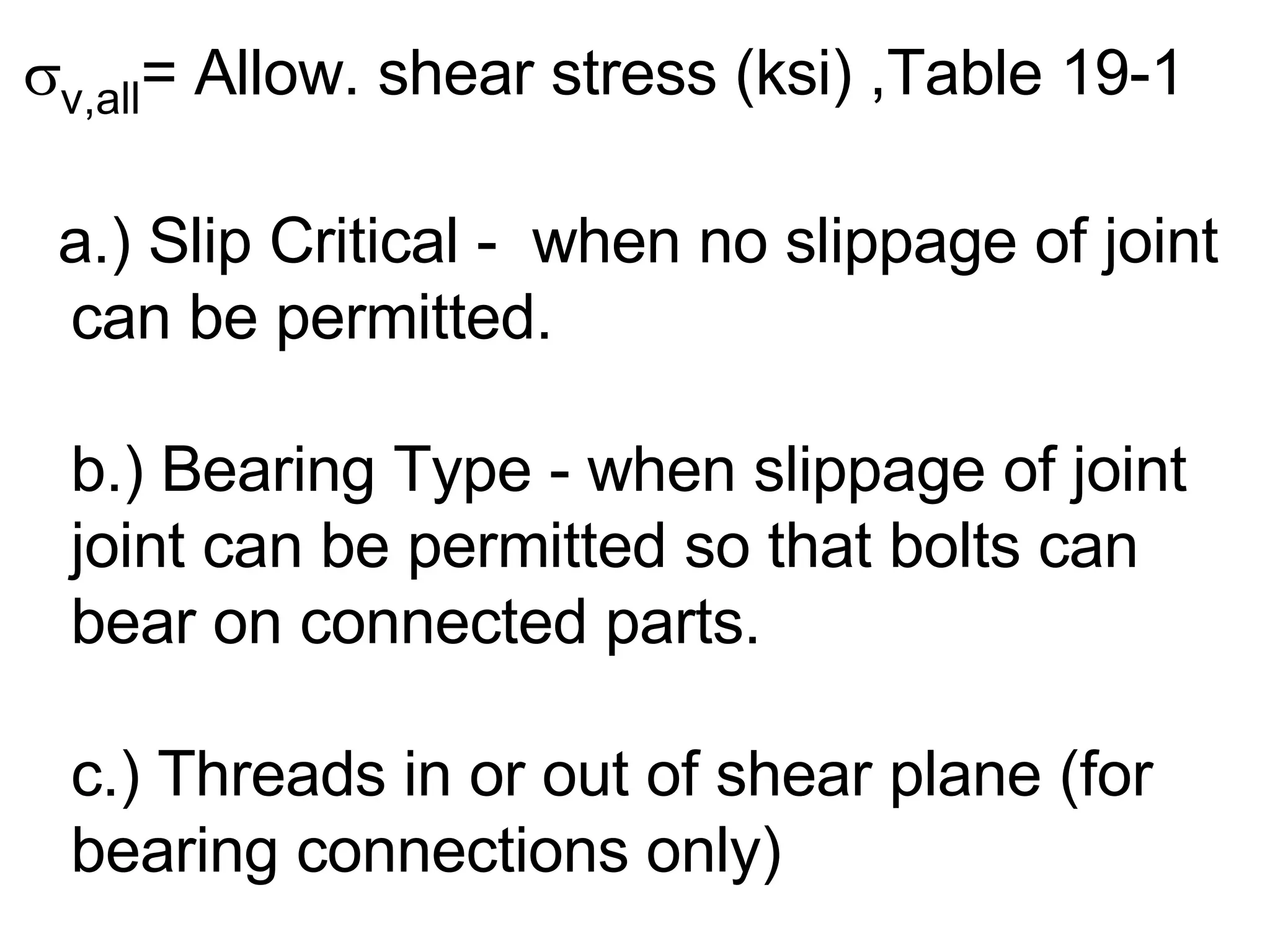

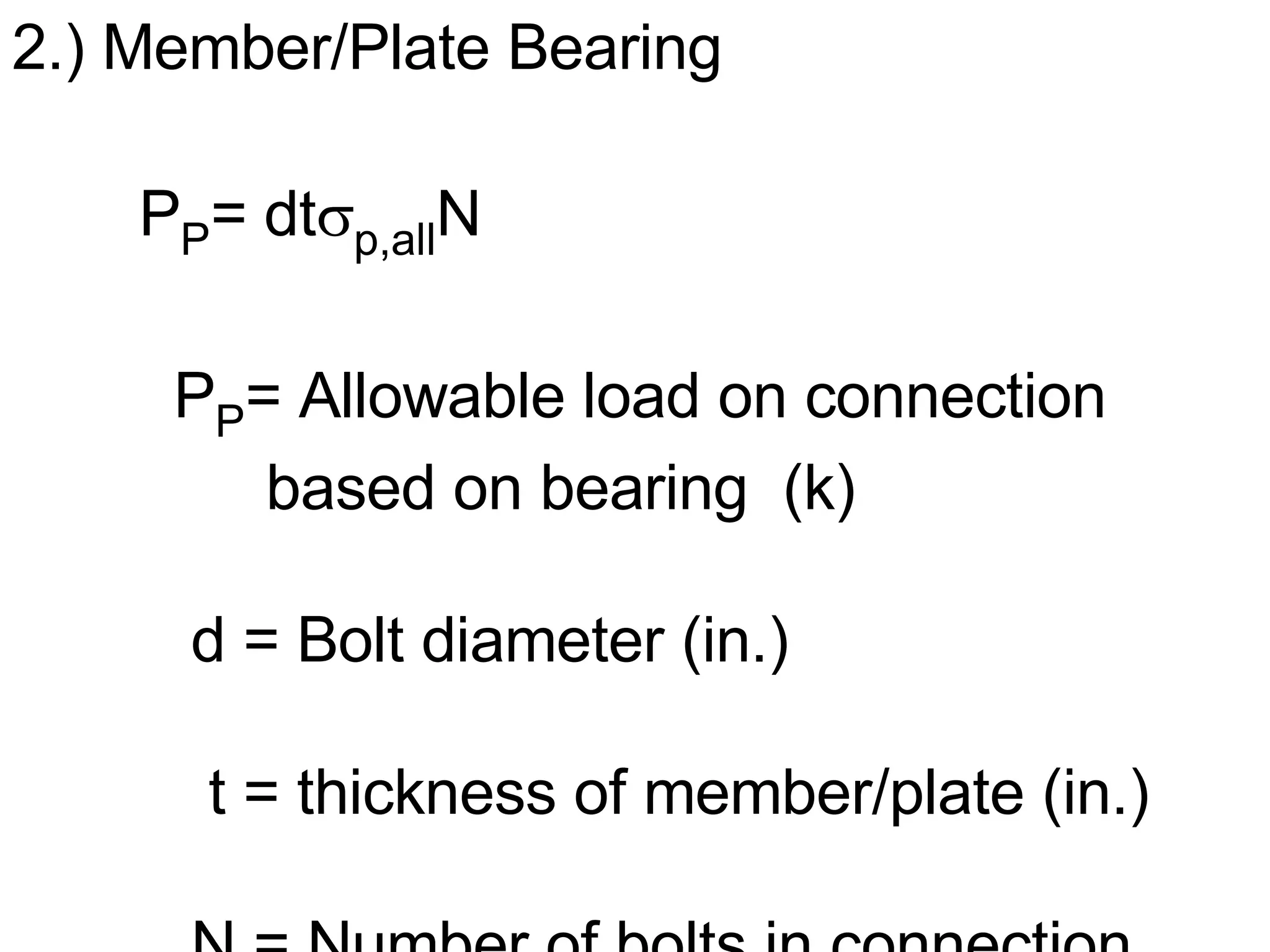

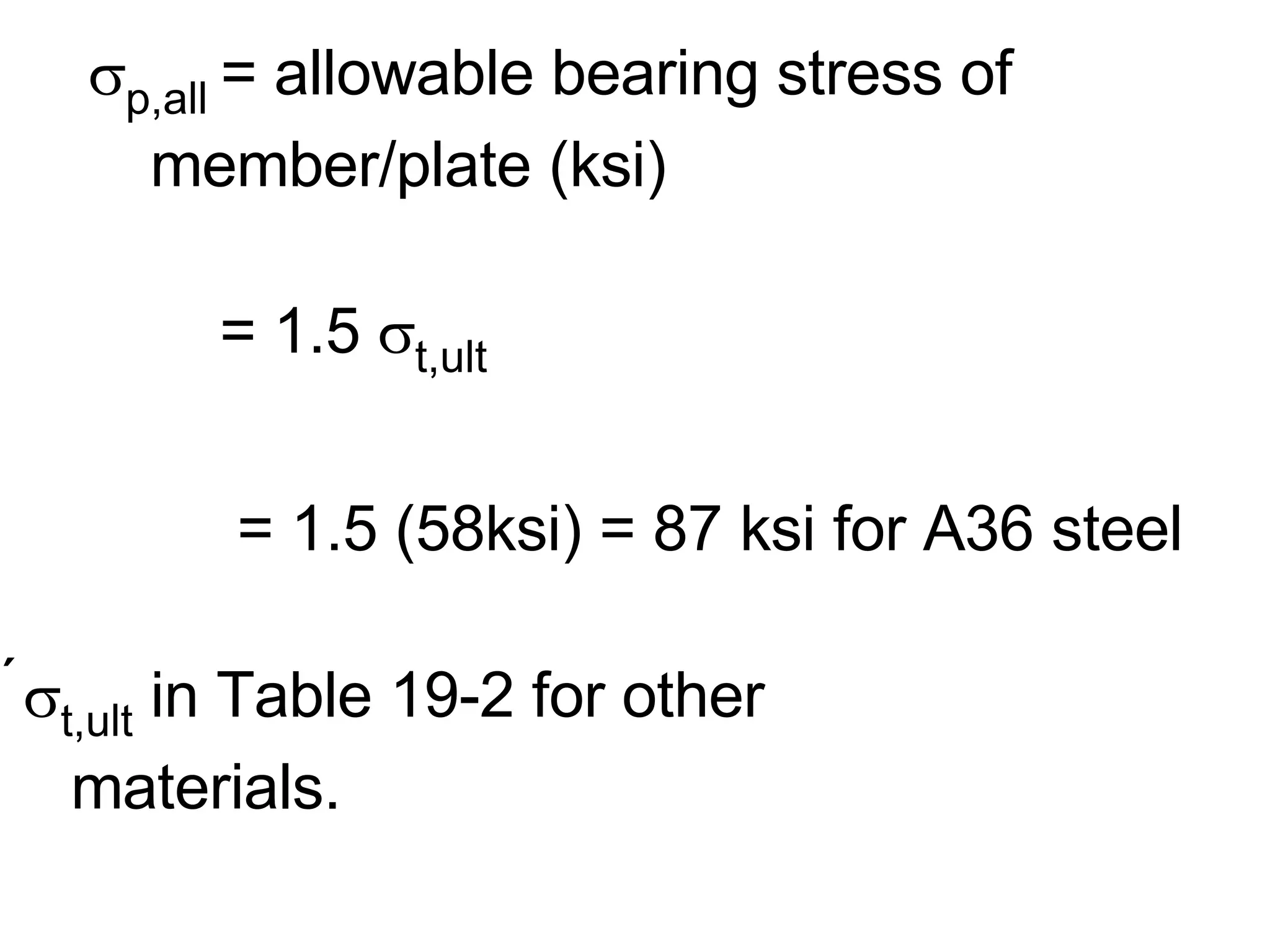

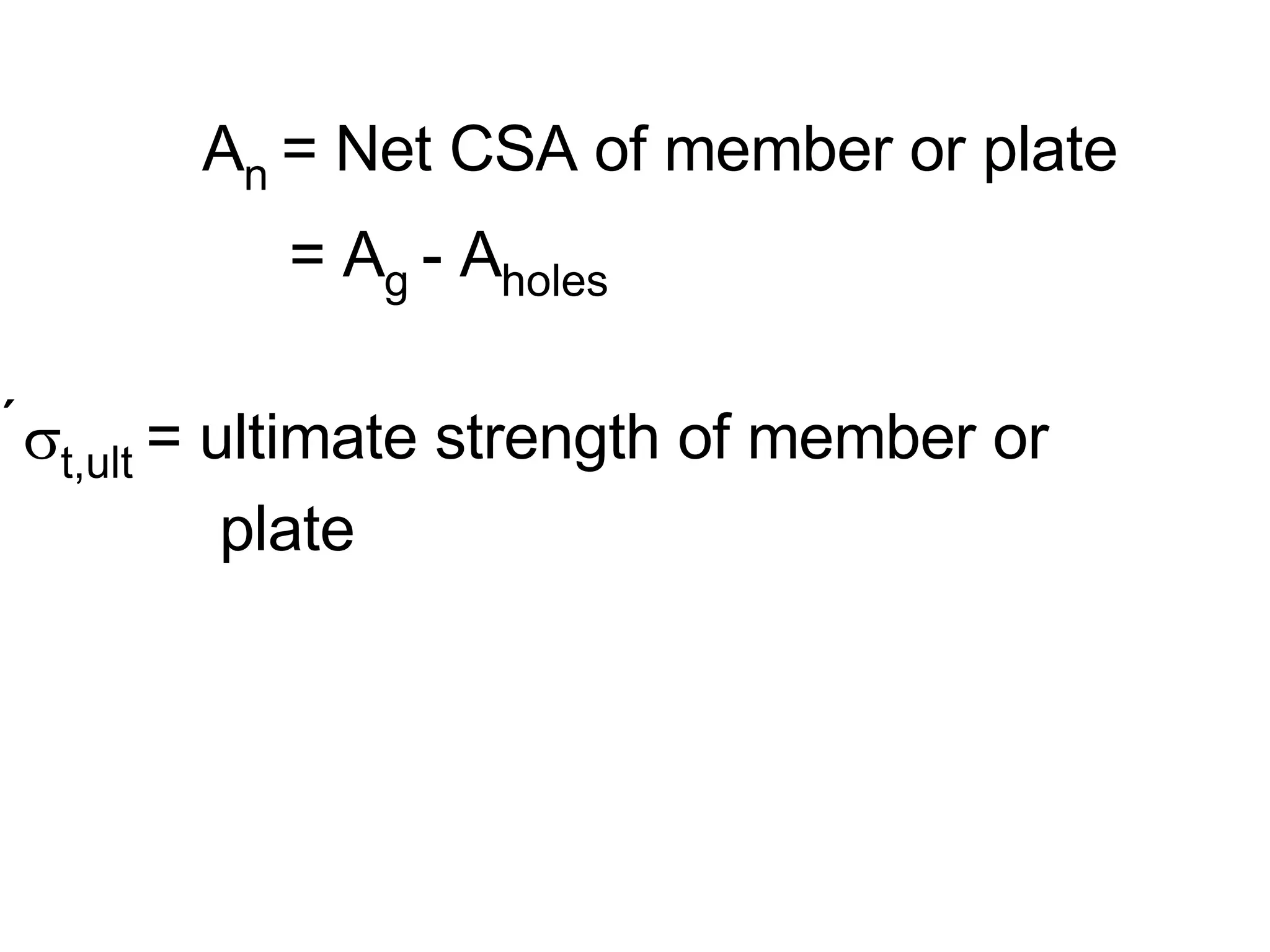

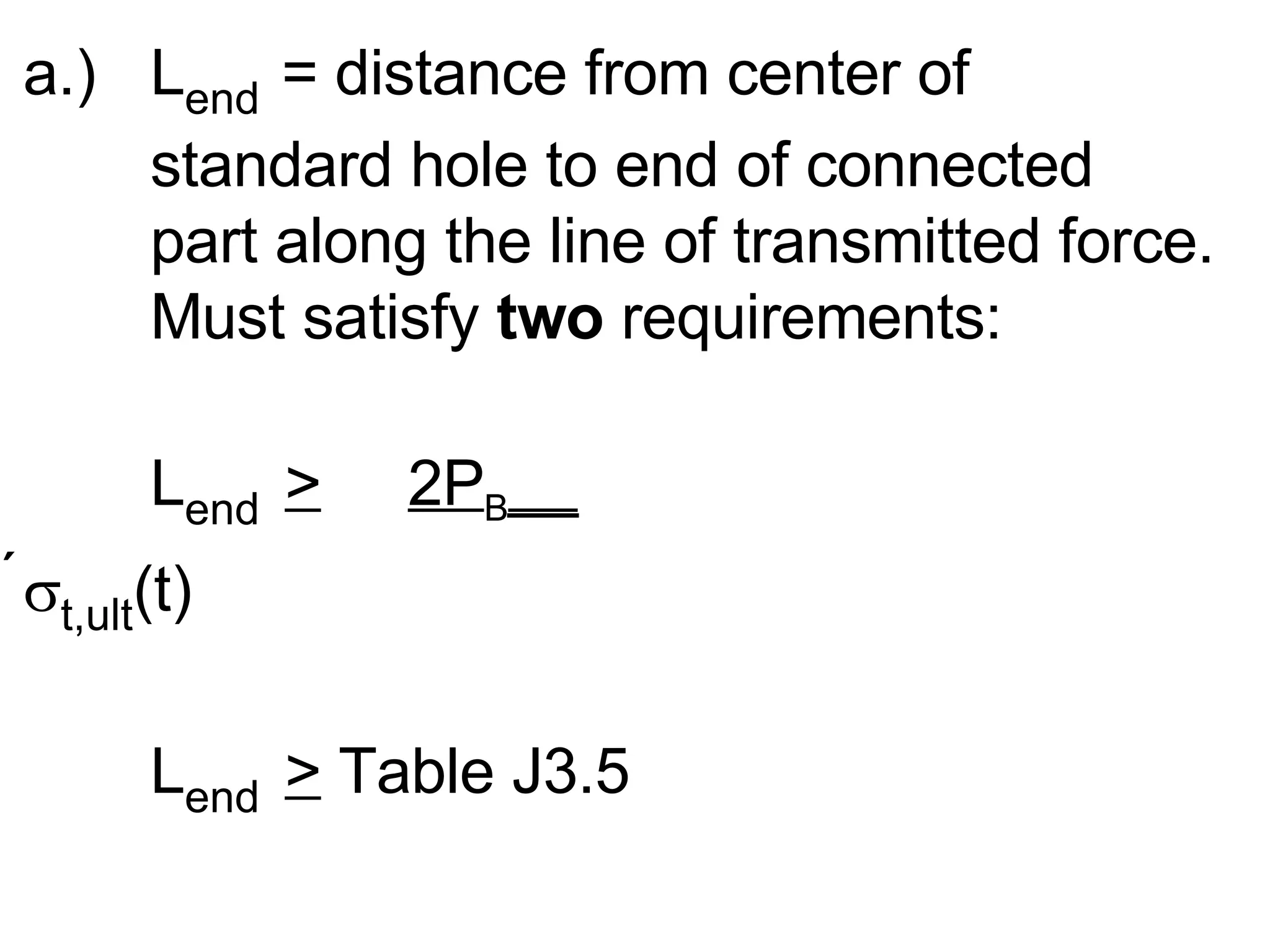

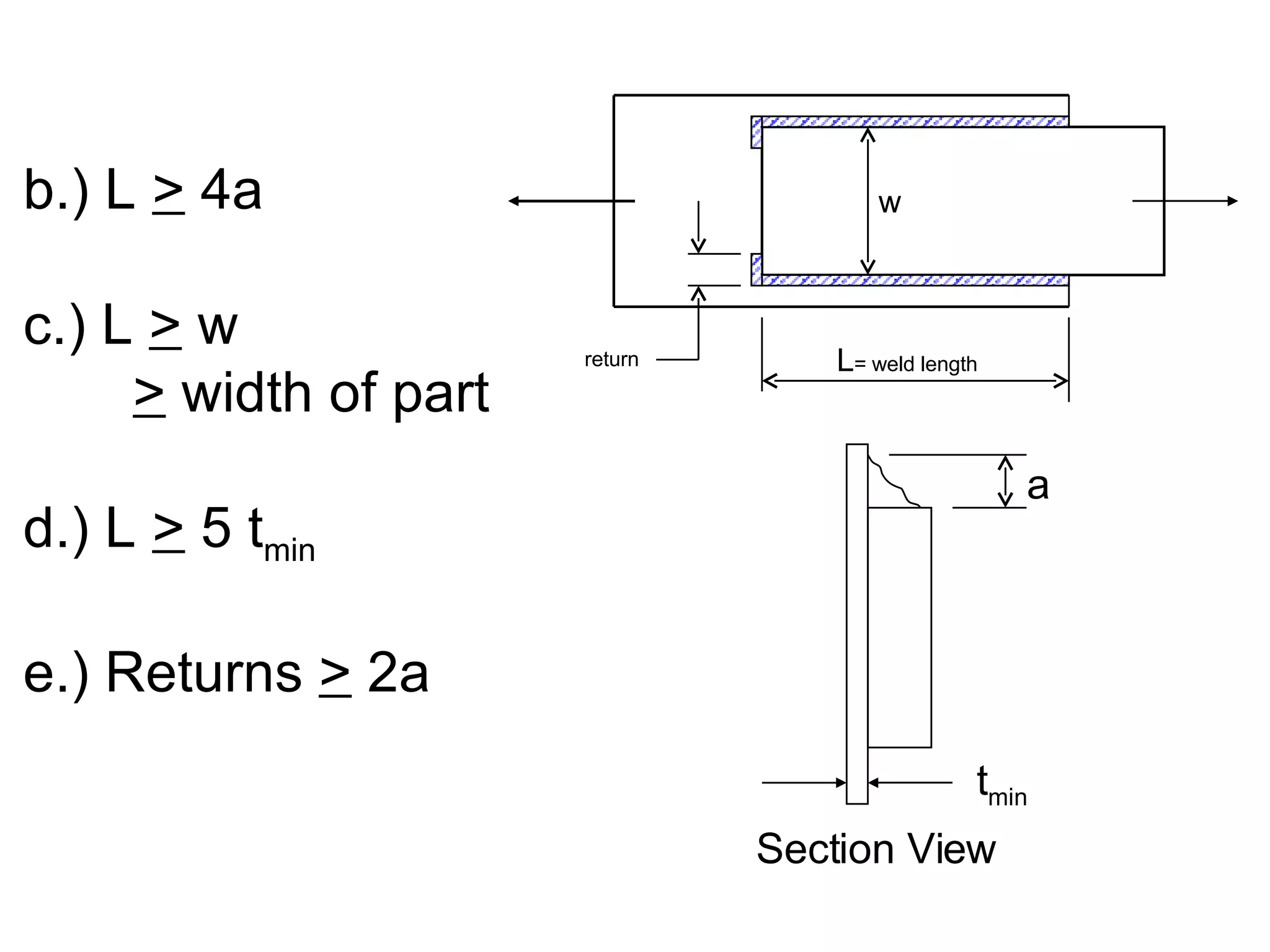

The document discusses bolted and welded steel connections. It describes different types of bolts used in structural steel connections and different types of bolted connections, including tension/compression, shear, and moment connections. It also discusses potential failure modes of bolted connections and design considerations to prevent these failures, including bolt shear, bearing, tension, and edge distances. The document then introduces welded connections, describing the welding process and different weld geometries. It discusses strength considerations for groove and fillet welds and design criteria for fillet weld size and length.