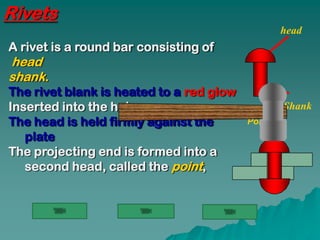

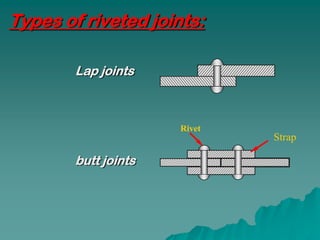

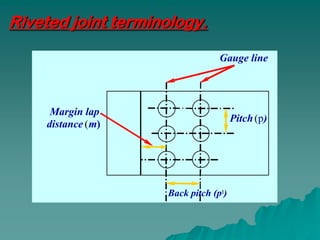

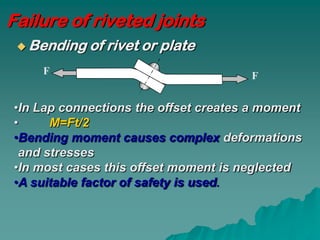

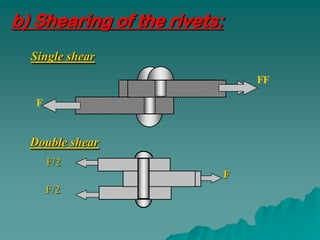

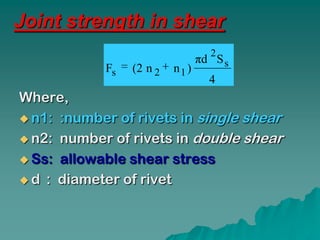

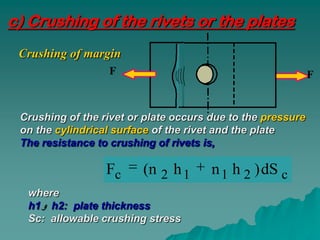

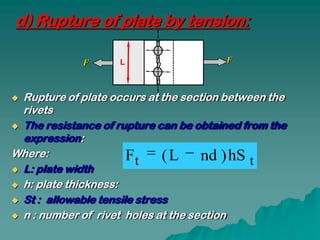

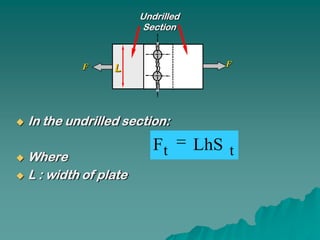

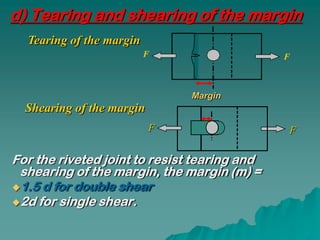

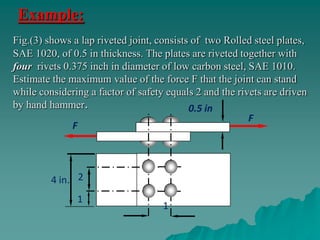

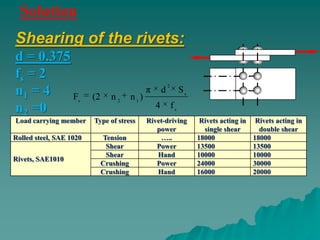

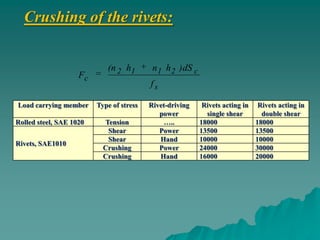

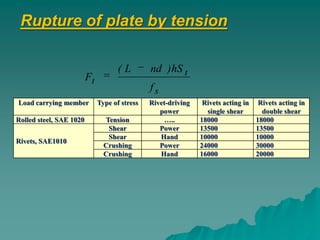

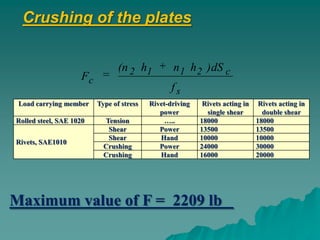

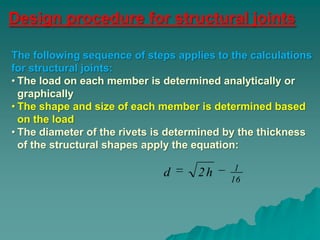

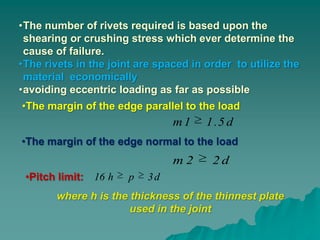

This document discusses riveted joints, including their applications, materials used, types of joints, and failure modes. Riveted joints are used in pressure vessels, boilers, tanks, bridges, ships, airplanes, cranes, buildings, and machinery. The document describes rivets and their components. It explains the types of riveted joints, including lap and butt joints. It then covers the potential failure modes of riveted joints, such as bending of rivets or plates, shearing of rivets, crushing of rivets or plates, rupture of plates by tension, and tearing or shearing of margins. The document provides examples of calculations for determining the load capacity of a ri