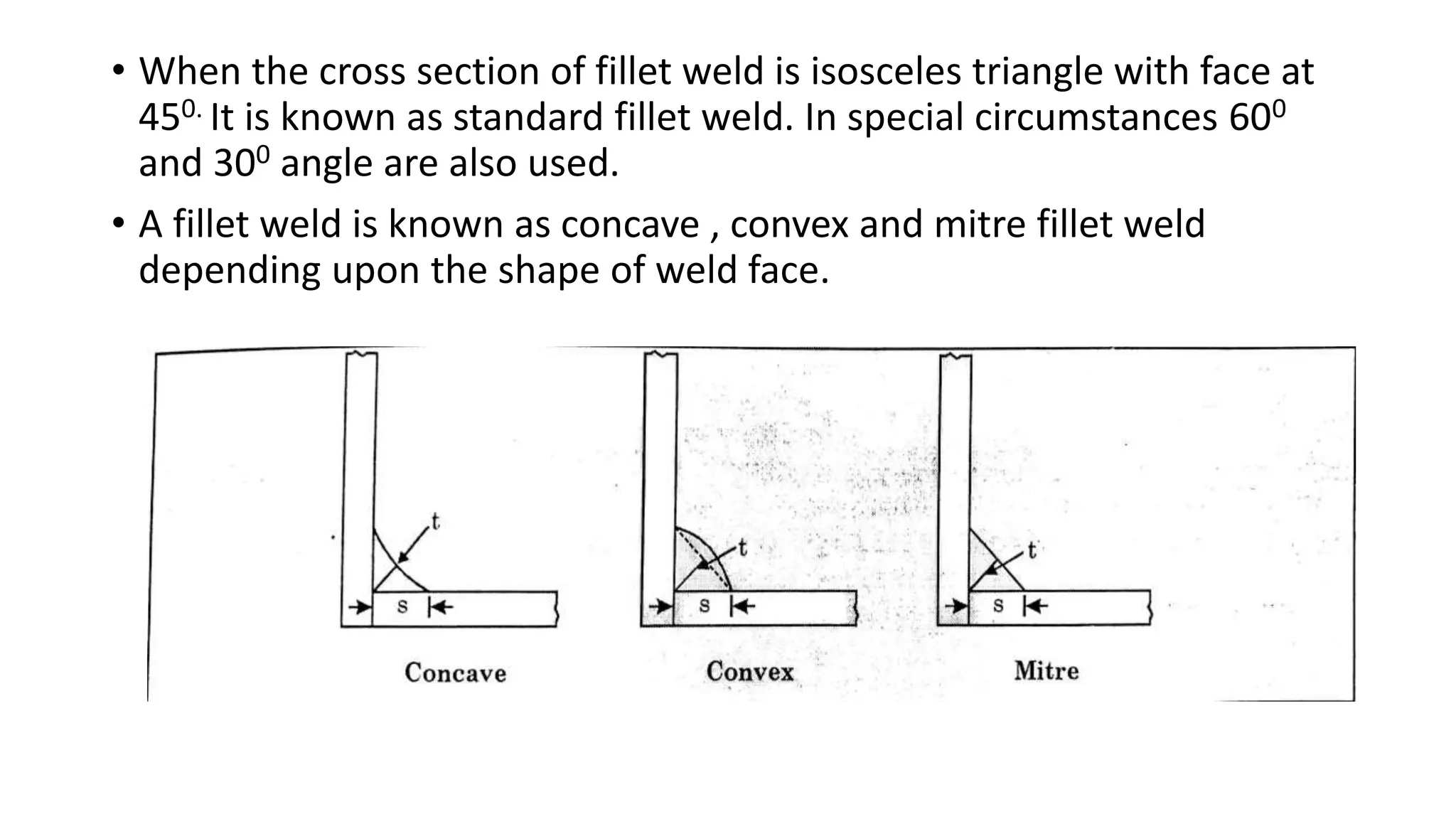

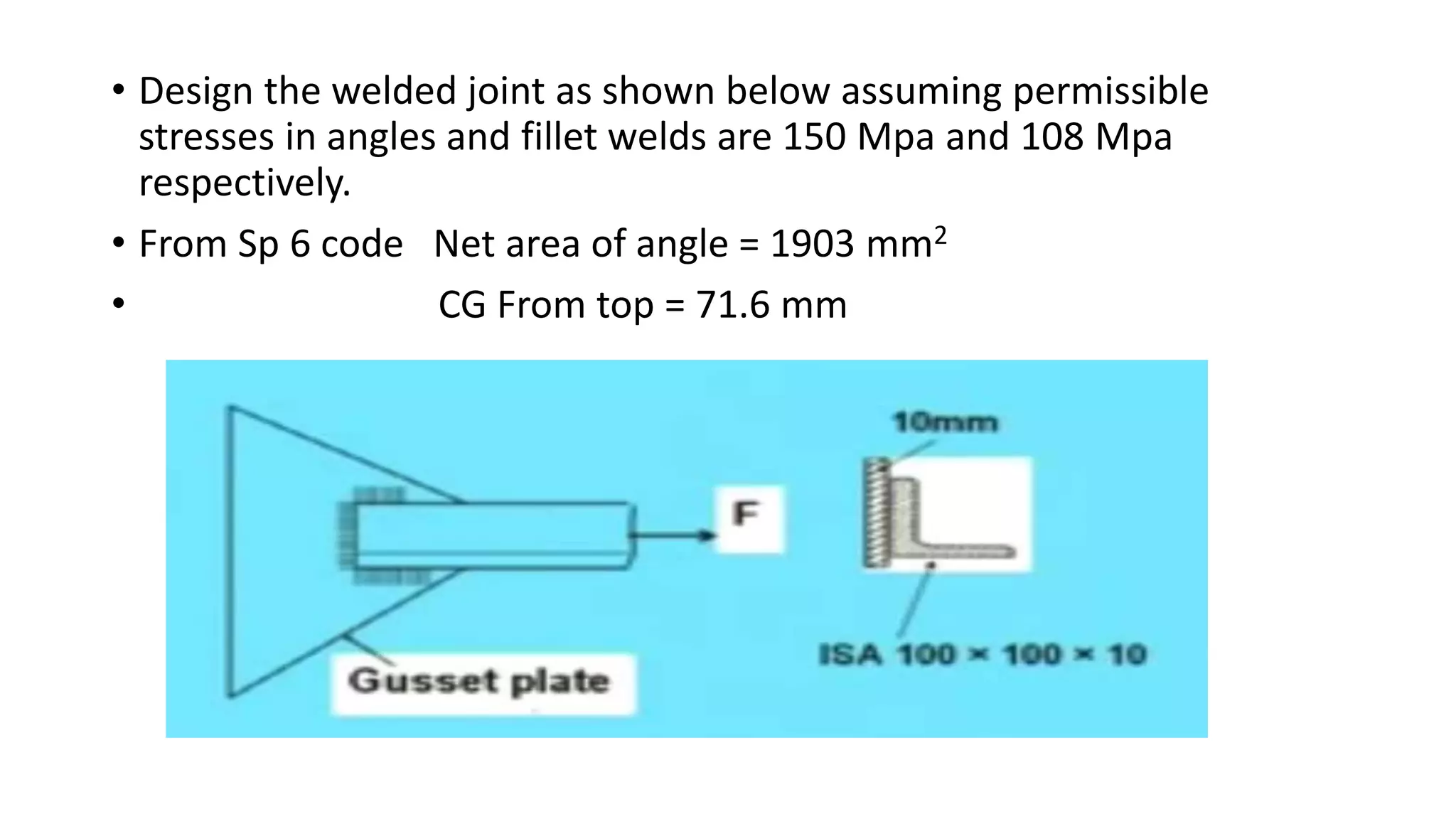

Welded connections can join metal pieces through a metallurgical bond. Common welded joints include butt joints, fillet welds, slot welds, and plug welds. Fillet welds join surfaces at right angles and have a triangular cross-section. Specifications cover weld sizes, lengths, and stresses. Advantages of welding include increased strength and reduced weight, while disadvantages include potential cracking and distortion during cooling. Design of welded joints involves calculating weld sizes and lengths to transmit required loads based on permissible stresses.