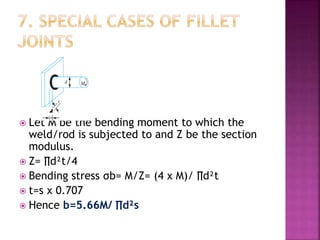

This document discusses welded connections. It begins by defining welding as the process of joining metals through heating and applying pressure or filler material. The document then covers the advantages and disadvantages of welded connections, different welding processes, types of welded joints including butt and fillet joints, stresses in welded joints, analyzing unsymmetrical welded sections under axial loads, and special cases of fillet joints subjected to torque or bending moments. Equations for calculating forces and stresses in various welded joint configurations are provided.