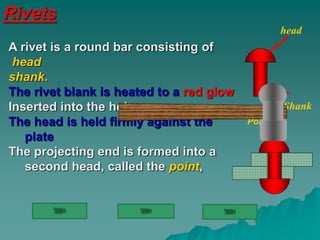

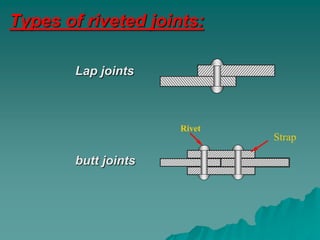

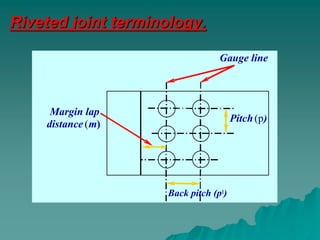

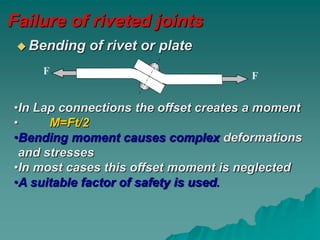

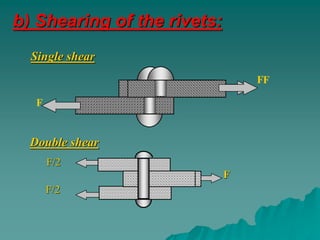

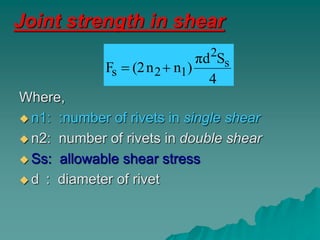

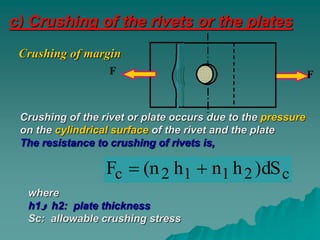

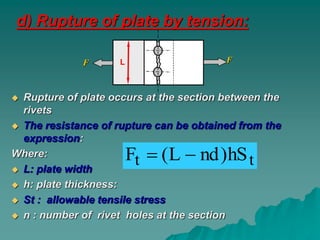

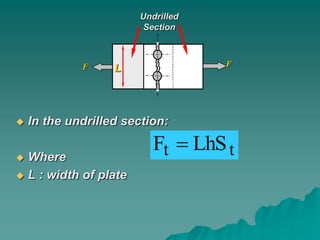

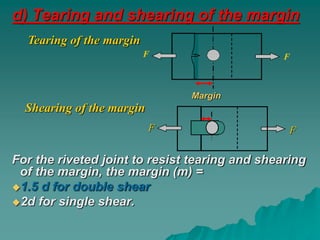

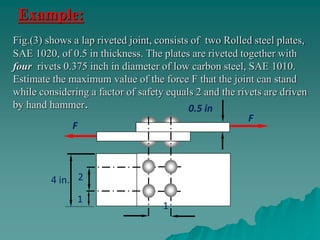

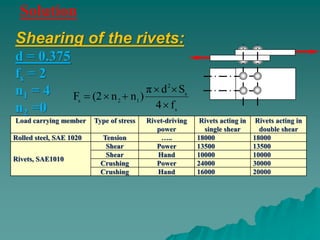

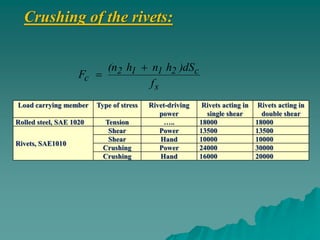

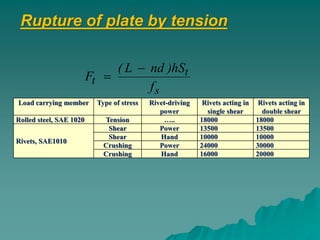

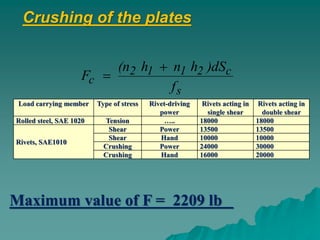

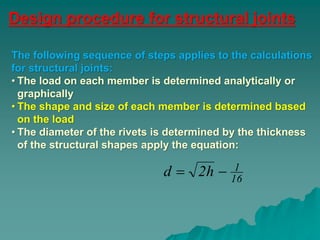

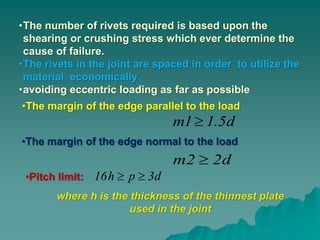

This document summarizes riveted joints, including their applications, components, types, and failure modes. Riveted joints are used to connect parts in pressure vessels, bridges, ships, airplanes, cranes, and buildings. A rivet consists of a head and shank. When forming a joint, rivets are inserted through holes in plates and the protruding end is hammered to form a second head. Common rivet materials include steel, nickel steel, brass, and aluminum. Key types of riveted joints are lap joints and butt joints. Failure can occur via bending of rivets or plates, shearing of rivets, crushing of rivets or plates, or rupture of