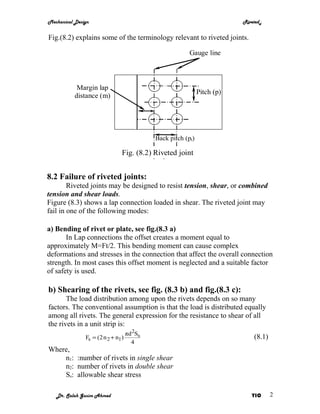

Riveting was commonly used to join metal parts before welding but is now less common. Rivets are cylindrical shafts inserted through holes in materials to be joined and formed into heads on both ends. Riveted joints can fail due to bending, shearing of rivets, crushing of rivets or plates, or tearing of materials. The document provides equations to calculate load capacities of riveted joints based on factors like rivet material properties, number of rivets, and whether rivets are in single or double shear. Design of riveted joints involves selecting rivet size, number and layout to optimize strength and load distribution.